Solar Inverter Fan - On-grid Inverter with Energy Storage 2000W

- Loading Port:

- Shenzhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Unit pc

- Supply Capability:

- 8000 Units/month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of On-Grid Inverter With Energy Storage 2000W

1.Pure sine wave output

2.Microprocessor controlled to guarantee stable charging system

3.Multiple operations: Grid tie, Off grid, and grid tie with backup

4.Built-in MPPT solar charger

5.LCD display panel for comprehensive information

6.Multiple communication

7.Green substitution for generators

8.User adjustable charging current up to 25A

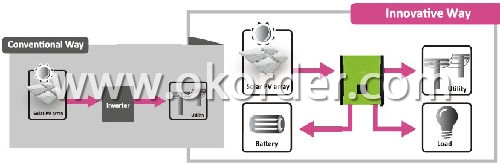

Feed-in is not only choice

In comparison with conventional grid-tie inverter, CNBM hybrid inverter is able to not only feed-in power to grid but also store solar power to battery for future usage and directly power to the loads.

Save money by discharging battery for self-consumption first

CNBM hybrid inverter can save money by using battery energy first when PV energy is low. Until battery energy is low, CNBM will extract AC power from the grid.

Power backup when AC failed

CNBM hybrid inverter can operate as an off-grid inverter to provide continuous power even without the grid.

It's perfect power solution for remote regions or temporary AC power source such as camping or flea market.

Datasheet of On-Grid Inverter With Energy Storage 2000W

MODEL | CNBM-H 2KW | CNBM-H 3KW |

RATED POWER | 2000W | 3000W |

GRID-TIE OPERATION | ||

PV INPUT (DC) | ||

Maximum DC power | 2250W | 3200W |

Nominal DC voltage / Maximum DC voltage | 300 VDC / 350VDC | 360 VDC / 500VDC |

Start voltage / Initial Feeding Voltage | 80 VDC / 120VDC | 116 VDC / 150 VDC |

MPP voltage range | 150 VDC ~ 320 VDC | 250 VDC ~ 450 VDC |

Number of MPP Trackers / Max. input current | 1 / 1×15A | 1 / 1×13A |

GRID OUTPUT (AC) | ||

Nominal Output Voltage | 101/110/120/127 VAC | 208/220/230/240 VAC |

Output Voltage Range | 88 - 127 VAC | 184 – 264.5 VAC |

Nominal Output Current | 18 A | 13.1 A |

Power Factor | > 0.99 | |

EFFICIENCY | ||

Maximum Conversion Efficiency (DC/AC) | 95% | 96% |

European Efficiency@ Vnominal | 94% | 95% |

OFF-GRID OPERATION | ||

AC INPUT | ||

AC Startup Voltage / Auto Restart Voltage | 60 - 70 VAC / 85VAC | 120 - 140 VAC / 180VAC |

Acceptable Input Voltage Range | 85 - 130 VAC | 170 - 280 VAC |

Maximum AC Input Current | 30A | 25A |

PV INPUT (DC) | ||

Maximum DC voltage | 350 VAC | 500 VAC |

MPP Voltage Range | 150 VAC ~ 320 VDC | 250 VAC ~ 450 VDC |

Maximum Input Current | 1 / 1×15A | 1 / 1×13A |

BATTERY MODE OUTPUT (AC) | ||

Nominal Output Voltage | 101/110/120/127 VAC | 208/220/230/240 VAC |

Output Frequency | 50 Hz / 60 Hz (auto sensing) | |

Output Waveform | Pure sine wave | |

Efficiency (DC to AC) | 90% | 93% |

HYBRID OPERATION | ||

PV INPUT (DC) | ||

Nominal DC voltage / Maximum DC voltage | 300 VDC / 350VDC | 360 VDC / 500VDC |

Start voltage / Initial Feeding Voltage | 80 VDC / 120VDC | 116 VDC / 150 VDC |

MPP voltage range | 150 VDC ~ 320 VDC | 250 VDC ~ 450 VDC |

Maximum Input Current | 1 / 1×15A | 1 / 1×13A |

GRID OUTPUT (AC) | ||

Nominal Output Voltage | 101/110/120/127 VAC | 208/220/230/240 VAC |

Output Voltage Range | 88 - 127 VAC | 184 – 264.5 VAC |

Nominal Output Current | 18 A | 13.1 A |

AC INPUT | ||

AC Startup Voltage / Auto Restart Voltage | 60 - 70 VAC / 85VAC | 120 - 140 VAC / 180VAC |

Acceptable Input Voltage Range | 85 - 130 VAC | 170 - 280 VAC |

Maximum AC Input Current | 30A | 25A |

BATTERY MODE OUTPUT (AC) | ||

Nominal Output Voltage | 101/110/120/127 VAC | 208/220/230/240 VAC |

Efficiency (DC to AC) | 90% | 93% |

BATTERY & CHARGER | ||

Nominal DC Voltage | 48 VDC | |

Maximum Charging Current | 25A | |

GENERAL | ||

PHYSICAL | ||

Dimension, D X W X H (mm) | 420 x 415 x 170 | |

Net Weight (kgs) | 15.5 | |

INTERFACE | ||

Communication Port | RS-232 / USB | |

Intelligent Slot | Optional SNMP, Modbus, and AS400 cards available | |

ENVIRONMENT | ||

Humidity | 0 ~ 90% RH (No condensing) | |

Operating Temperature | 0 to 40°C | |

Altitude | 0 ~ 1000 m | |

COMPLIANCE | ||

Standard | CE, VDE 0126-1-1,VDE-AR-N 4105 | |

- Q: Can a solar inverter be used with dual-axis solar trackers?

- Yes, a solar inverter can be used with dual-axis solar trackers. A solar inverter is responsible for converting the direct current (DC) generated by the solar panels into alternating current (AC) that can be used to power electrical devices or be fed into the grid. The dual-axis solar trackers enable the solar panels to follow the sun's movement in both horizontal and vertical directions, maximizing their exposure to sunlight throughout the day. The solar inverter can still perform its function of converting DC to AC regardless of the type of solar tracking system used.

- Q: What is the role of power factor correction in a solar inverter?

- The role of power factor correction in a solar inverter is to improve the efficiency and performance of the inverter by correcting and optimizing the power factor of the electrical system. By adjusting the phase relationship between voltage and current, power factor correction ensures that the inverter draws and supplies power more effectively, reducing energy losses, improving power quality, and minimizing harmonics in the system. This helps to maximize the overall power output and reliability of the solar inverter, leading to better energy conversion and utilization.

- Q: Can a solar inverter be connected to a smart home or monitoring system?

- Yes, a solar inverter can be connected to a smart home or monitoring system. Many modern solar inverters have built-in communication capabilities, such as Wi-Fi or Ethernet connectivity, which allows them to connect to a smart home or monitoring system. This enables users to monitor and control their solar power generation and energy consumption remotely, receive real-time data and alerts, and optimize their energy usage for maximum efficiency.

- Q: What is the role of a solar inverter in a solar-powered electric vehicle charging station?

- The role of a solar inverter in a solar-powered electric vehicle charging station is to convert the direct current (DC) produced by the solar panels into alternating current (AC) that can be used to charge electric vehicles. The inverter ensures that the electricity generated by the solar panels is compatible with the charging station and the electric vehicle's charging requirements.

- Q: Can a solar inverter be used with solar-powered electric vehicle charging stations?

- Yes, a solar inverter can be used with solar-powered electric vehicle charging stations. A solar inverter is necessary to convert the DC (direct current) power generated by solar panels into AC (alternating current) power that can be used by electric vehicle charging stations. This allows the solar power to be fed into the charging station and used to charge electric vehicles.

- Q: How does the total harmonic distortion affect the performance of a solar inverter?

- Total harmonic distortion (THD) refers to the measure of distortion or deviation from the ideal sine wave in an electrical system. In the case of a solar inverter, high THD levels can negatively impact its performance. Excessive harmonic distortion can lead to increased heat generation, reduced power efficiency, and potential damage to connected devices. Moreover, higher THD levels may also result in poor power quality, affecting the overall reliability and stability of the inverter's output. Therefore, minimizing total harmonic distortion is crucial to ensure optimal performance and reliable operation of a solar inverter.

- Q: Can a solar inverter be used with solar-powered remote sensing systems?

- Yes, a solar inverter can be used with solar-powered remote sensing systems. A solar inverter is responsible for converting the direct current (DC) generated by solar panels into alternating current (AC) that can be used to power various devices and systems. In the case of solar-powered remote sensing systems, the solar inverter would be an essential component in converting the DC power from the solar panels into the required AC power to operate the remote sensing equipment.

- Q: What is the role of a fault detection system in a solar inverter?

- The role of a fault detection system in a solar inverter is to monitor the performance and health of the inverter and solar panels, and to detect any faults or abnormalities that may occur during operation. It helps to identify issues such as short circuits, voltage fluctuations, overheating, or component failures, which can affect the efficiency and safety of the solar power system. By quickly identifying and alerting the user or system operator about these faults, the fault detection system allows for timely maintenance or repair, ensuring optimal performance and longevity of the solar inverter.

- Q: Can a solar inverter be used in systems with different module currents?

- Yes, a solar inverter can be used in systems with different module currents. Solar inverters are designed to convert the DC power produced by the solar panels into AC power for use in the electrical grid or for powering appliances. They typically have a wide range of input voltage and current ratings to accommodate different solar panel configurations. As long as the total power output of the solar panels is within the specifications of the inverter, it can be used in systems with varying module currents.

- Q: Can a solar inverter be used with a three-phase electrical system?

- Yes, a solar inverter can be used with a three-phase electrical system. In fact, many solar inverters are designed to work with three-phase systems. These inverters are capable of converting the direct current (DC) generated by the solar panels into alternating current (AC) that can be used by the three-phase electrical system.

Send your message to us

Solar Inverter Fan - On-grid Inverter with Energy Storage 2000W

- Loading Port:

- Shenzhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Unit pc

- Supply Capability:

- 8000 Units/month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords