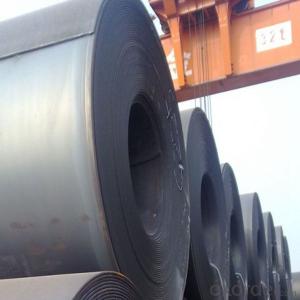

Hot Rolled Steel Sheets Steel Coils Made in China SS400

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC:

1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

DETAILS:

Thickness | 0.5-100mm |

Width | 1250mm,1500mm,1800mm,2000mm.,2500mm or as required |

Length | 2000-12000mm |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | A36,SS400,SPCC,SPHC, Q195, Q 235,Q345 |

Tehnique | Hot rolled;cold rolled |

Payment | TT ,L/C |

Packing | Standard seaworthy packing or as required |

Market | Mild east, North/South America, Europe, Asia,Africa etc |

Certificate | BV,SGS,MTC |

Delivery time | 30-45days after confirming the order |

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

DETAILED PICTURES FOR STEEL COILS

PAYMENT&DELIVERY FOR STEEL COILS/SHEETS

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

FEATURES OF STEEL COILS

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

FAQ

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q:What is the typical yield strength of steel sheets?

- The typical yield strength of steel sheets can vary depending on the grade and type of steel being used. However, for mild steel sheets commonly used in construction and manufacturing, the typical yield strength is around 250 megapascals (MPa) or 36,000 pounds per square inch (psi). Higher strength steels, such as high-strength low-alloy (HSLA) steels or advanced high-strength steels (AHSS), can have yield strengths ranging from 300 to 600 MPa (43,500 to 87,000 psi) or even higher. It is important to note that these values are general estimates and specific steel grades may have slightly different yield strengths.

- Q:Are steel sheets suitable for roofing?

- Yes, steel sheets are suitable for roofing. Steel is a strong and durable material that can withstand various weather conditions, including high winds, heavy rain, and snow. It also offers excellent protection against fire and is resistant to corrosion. Additionally, steel sheets are lightweight, easy to install, and can be designed in different styles and colors to enhance the aesthetic appeal of a building.

- Q:Can steel sheets be used in the food processing industry?

- The food processing industry can utilize steel sheets for various purposes. Steel, being a highly versatile and durable material, finds extensive applications in this industry. Steel sheets are commonly employed in the construction of tables, work surfaces, shelves, cabinets, and containers, among other equipment and machinery. The suitability of steel sheets for the food processing industry arises from their unique properties. Firstly, steel exhibits resistance to corrosion, a crucial factor in an environment where food and liquids are constantly present. This resistance ensures that the steel sheets maintain their structural integrity and do not contaminate the food being processed. Secondly, steel is easily cleanable and sanitizable, a critical requirement for maintaining high standards of hygiene in the food processing industry. The smooth surface of steel sheets allows for easy wiping and prevents the accumulation of dirt, bacteria, and other contaminants that could compromise the quality and safety of the food. Furthermore, steel sheets possess exceptional strength and can withstand heavy loads and physical impacts. This makes them ideal for use in equipment and machinery that handle large quantities of food or require frequent movement or transportation. Additionally, steel is a non-porous material, meaning it does not absorb or retain odors, flavors, or stains from the food being processed. This property ensures that the steel sheets do not affect the taste or quality of the food. To summarize, steel sheets are widely utilized in the food processing industry due to their durability, corrosion resistance, ease of cleaning, and non-porous nature. They provide a reliable and hygienic solution for constructing essential equipment and machinery in food processing operations.

- Q:Can steel sheets be used in food-grade applications?

- Yes, steel sheets can be used in food-grade applications. Stainless steel sheets are commonly used in various food processing and handling equipment, as they offer excellent resistance to corrosion, durability, and ease of cleaning.

- Q:Can steel sheets be used for insulation cladding?

- No, steel sheets are not typically used for insulation cladding. Insulation cladding is typically made of materials with better insulating properties, such as foam boards or reflective foil. Steel sheets are more commonly used for structural purposes or as a protective covering.

- Q:What are the safety considerations when working with steel sheets?

- When working with steel sheets, there are several important safety considerations to keep in mind: 1. Personal Protective Equipment (PPE): It is crucial to wear appropriate PPE to protect yourself from potential hazards. This may include safety glasses or goggles, gloves, steel-toed boots, and a hard hat. 2. Lifting and handling: Steel sheets can be heavy and awkward to handle. Use proper lifting techniques, such as bending your knees and keeping your back straight, or use mechanical lifting equipment like cranes or forklifts. Never attempt to lift a sheet that is too heavy for you alone. 3. Slips, trips, and falls: Steel sheets can create slippery surfaces, especially when wet or oily. Keep work areas clean and free of debris, and use non-slip mats or flooring where appropriate. Be cautious of trip hazards, such as cords or tools, and use caution when moving around the work area. 4. Sharp edges and corners: Steel sheets often have sharp edges and corners that can cause cuts or injuries. Use caution when handling and moving them, and wear gloves to protect your hands. If necessary, use edge protectors or file down any sharp edges to reduce the risk of injuries. 5. Fire hazards: Steel sheets can be flammable when exposed to high temperatures or sparks. Ensure that work areas are clear of flammable materials and follow proper fire safety procedures, such as having fire extinguishers readily available and knowing how to use them. 6. Noise and vibration: Working with steel sheets can generate significant noise and vibration. Wear ear protection, such as earplugs or earmuffs, to protect your hearing. If using power tools, ensure they are properly maintained and have vibration-dampening features to minimize the risk of hand-arm vibration syndrome. 7. Adequate ventilation: Some steel sheets may release fumes or dust when cut or welded. Ensure that the workspace is well-ventilated to prevent the accumulation of harmful gases or particles. If necessary, use exhaust fans or wear respiratory protection to avoid inhalation of hazardous substances. By following these safety considerations, you can minimize the risks associated with working with steel sheets and create a safer work environment for yourself and others.

- Q:Can steel sheets be used for signage or displays?

- Yes, steel sheets can definitely be used for signage or displays. Steel is a versatile material that offers durability and strength, making it suitable for both indoor and outdoor applications. Steel sheets can be cut, bent, or welded into various shapes and sizes, allowing for the creation of custom signage or displays. The smooth surface of steel sheets provides an excellent canvas for painting, printing, or applying vinyl graphics, making them ideal for showcasing logos, messages, or visual content. Additionally, steel sheets can be powder coated or galvanized to enhance their resistance to corrosion, ensuring long-lasting and attractive signage or displays.

- Q:Can steel sheets be used for electromagnetic shielding?

- Yes, steel sheets can be used for electromagnetic shielding. Steel is a highly conductive material, which means it can effectively divert and absorb electromagnetic waves, preventing them from penetrating through the shield. This makes steel sheets an excellent choice for applications requiring electromagnetic shielding, such as electronic devices, power transformers, and MRI machines.

- Q:Are steel sheets suitable for railway carriages?

- Indeed, railway carriages find steel sheets to be a fitting option. The robustness, resilience, and capacity to endure the ceaseless strain linked with train operations render steel a favored material for these carriages. Steel sheets provide the essential structural strength to uphold the carriage and its occupants, simultaneously safeguarding against impacts and harsh weather conditions. Furthermore, steel boasts relative cost-effectiveness and widespread accessibility, rendering it an optimal selection for the creation of railway carriages.

- Q:Are the steel sheets available in different colors?

- Yes, steel sheets are available in different colors. Steel sheets can be coated or painted in various colors to match specific aesthetic or design preferences. The color options may vary depending on the manufacturer or supplier, but common colors include black, white, gray, blue, red, and green. Additionally, some steel sheets may feature a textured or patterned finish to further enhance their visual appeal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Sheets Steel Coils Made in China SS400

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords