430 201 202 304 304l 316 316l 321 310s 309s 904l Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

430 201 202 304 304l 316 316l 321 310s 309s 904l Stainless Steel Sheet

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

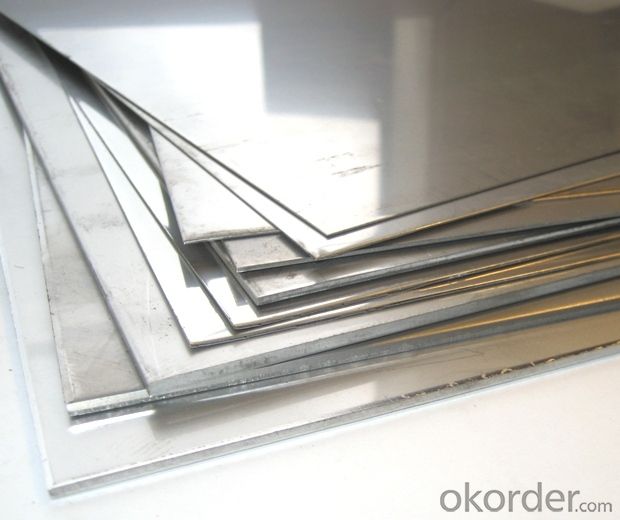

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q:What are the different types of perforations available for stainless steel sheets?

- Stainless steel sheets offer several options for perforations, each with its own purpose and characteristics. Here are some of the most common types available: 1. Round Perforations: The most widely used type, these consist of evenly spaced round holes punched through the sheet. They provide good airflow, visibility, strength, and durability. 2. Square Perforations: Similar to round perforations, square ones have evenly spaced square holes. They are preferred for a more modern and geometric aesthetic, creating visually appealing patterns. 3. Slotted Perforations: These have elongated, rectangular holes for better drainage and airflow. They are ideal for grilles, screens, and filters. 4. Hexagonal Perforations: Featuring hexagon-shaped holes, this type offers an interesting visual pattern and increased strength and rigidity. 5. Decorative Perforations: Designed to enhance the aesthetic appeal, these come in various shapes, sizes, and patterns such as floral or custom designs. They are commonly used in architecture, interior design, and decorative panels. 6. Micro Perforations: These are extremely small and closely spaced holes for applications requiring high precision and fine filtering, like speaker grilles, ventilation systems, or sieves. It's important to note that the availability of specific perforation types may vary depending on the supplier or manufacturer. Additionally, some suppliers may offer custom perforation options to meet unique requirements or design preferences.

- Q:Can stainless steel sheets be used for insulation?

- Stainless steel sheets are not typically used as insulation materials. While stainless steel has excellent heat resistance and is commonly used in various applications due to its durability and corrosion resistance, it does not possess good insulation properties. Insulation materials are designed to minimize heat transfer by reducing conduction, convection, and radiation. They typically have low thermal conductivity, which means they are effective in preventing heat transfer. Stainless steel, on the other hand, has high thermal conductivity, meaning it can conduct heat easily. To achieve insulation, it is more common to use materials such as fiberglass, mineral wool, foam boards, or reflective barriers. These materials have lower thermal conductivity and can effectively trap air or create a barrier that restricts the transfer of heat. By comparison, stainless steel sheets would not provide the same level of insulation as these specialized materials. However, stainless steel sheets can still be used in construction or industrial settings for their other properties, such as strength, corrosion resistance, and aesthetic appeal.

- Q:What does stainless steel plate mean?

- Stainless steel plate, the surface of the board is bright and clean, with high plasticity, toughness and mechanical strength, acid, alkaline gas, solution and other media corrosion. It is an alloy steel which is not easily rusted, but it is not absolutely rusty. Stainless steel plate refers to the atmosphere, steam and water and other weak medium corrosion of steel plate, and acid resistant steel plate refers to acid, alkali, salt and other chemical corrosive medium corrosion of steel plate. Stainless steel plate has been published since the beginning of twentieth Century, and now has a history of more than 1 centuries.

- Q:How do I prevent galvanic corrosion on stainless steel sheets?

- To prevent galvanic corrosion on stainless steel sheets, you can consider a few measures. Firstly, ensure that you use compatible metals when in contact with stainless steel to avoid creating a galvanic couple. Additionally, using insulation or separating materials, such as plastic or rubber gaskets, between dissimilar metals can help prevent galvanic corrosion. Regular cleaning and maintenance of stainless steel surfaces can also mitigate the risk of corrosion. Lastly, applying protective coatings or using corrosion inhibitors can provide an extra layer of defense against galvanic corrosion on stainless steel sheets.

- Q:What is the Young's modulus of stainless steel sheets?

- The Young's modulus of stainless steel sheets typically ranges from 190 to 220 gigapascals (GPa).

- Q:Are stainless steel sheets suitable for roofing applications?

- Certainly, roofing applications can benefit from the use of stainless steel sheets. Stainless steel possesses qualities such as durability, corrosion resistance, and strength, rendering it an excellent choice for roofs. It exhibits remarkable tolerance to severe weather conditions like extreme temperatures, strong winds, and heavy rainfall. Moreover, stainless steel sheets possess fire-resistant properties, thereby enhancing the safety level of the roof. Furthermore, stainless steel boasts an extended lifespan, necessitating minimal maintenance and repairs. In summary, stainless steel sheets offer a dependable and enduring solution for roofing needs.

- Q:Can stainless steel sheets be used for escalator cladding?

- Yes, stainless steel sheets can be used for escalator cladding. Stainless steel is a durable and corrosion-resistant material that can withstand the daily wear and tear of escalator usage. It provides a sleek and modern appearance while also offering protection and easy maintenance.

- Q:How do you prevent fingerprints and smudges on stainless steel sheets?

- To prevent fingerprints and smudges on stainless steel sheets, there are a few effective methods you can follow: 1. Clean with microfiber cloth: Use a soft microfiber cloth to wipe the stainless steel surface. Microfiber is gentle and won't leave any scratches or streaks. Avoid using rough materials like paper towels or abrasive sponges. 2. Use a stainless steel cleaner: Invest in a high-quality stainless steel cleaner specifically designed for removing fingerprints and smudges. Follow the instructions on the cleaner and apply it evenly on the surface using a cloth or a sponge. Wipe off any excess cleaner with a clean cloth. 3. Apply baby oil or mineral oil: Apply a small amount of baby oil or mineral oil on a cloth and rub it gently over the stainless steel surface. This will create a thin protective layer that helps prevent fingerprints and smudges from sticking to the metal. 4. Avoid touching the surface with bare hands: One of the main causes of fingerprints and smudges is direct contact with hands. Try to handle stainless steel sheets with clean, dry hands or wear gloves if necessary. This will help minimize the transfer of oils and residue onto the surface. 5. Regular cleaning routine: Establish a regular cleaning routine for your stainless steel sheets. Wipe them down with a microfiber cloth or stainless steel cleaner at least once a week, or more frequently in high-traffic areas. This will prevent the buildup of oils and grime, reducing the chances of fingerprints and smudges. By following these methods, you can effectively prevent fingerprints and smudges on stainless steel sheets, keeping them looking clean and shiny for an extended period of time.

- Q:How do you prevent discoloration on stainless steel sheets?

- There are several steps you can take to prevent discoloration on stainless steel sheets. Firstly, it is essential to clean the surface regularly. Use mild soap or detergent with warm water and avoid abrasive cleaners or scrubbing pads that can cause scratches. Secondly, avoid using harsh chemicals or cleaners that contain chlorine, bleach, ammonia, or acids. Stick to mild and non-abrasive cleaners specifically made for stainless steel. After cleaning, make sure to rinse the sheet thoroughly with clean water to remove any residue from the cleaning solution. Residual chemicals can cause discoloration if left on the surface for too long. It is important to dry the stainless steel sheet completely after cleaning and rinsing. Moisture left on the surface can lead to water spots or staining, especially in areas with hard water. Use a soft cloth or towel to remove all moisture and ensure a dry and shiny surface. Applying protective coatings or sealants designed for stainless steel can help prevent discoloration. These coatings create a barrier that protects the surface from environmental factors like humidity, oxidation, and staining. Proper handling and care are also crucial. Avoid dragging or sliding objects across the sheets to prevent scratches or abrasions that may lead to discoloration. Handle the sheets with care, using clean gloves or a soft cloth to minimize the risk of surface damage. Regularly inspect the stainless steel sheets for any signs of discoloration or damage. Address any issues promptly by following the appropriate cleaning and maintenance procedures to prevent further damage and maintain the appearance of the stainless steel. By following these preventive measures, you can effectively minimize discoloration on stainless steel sheets and keep them looking clean, shiny, and free from stains for a longer period of time.

- Q:Can stainless steel sheets be used in manufacturing processes?

- Yes, stainless steel sheets can be used in manufacturing processes. Stainless steel is a highly versatile and durable material that is commonly used in various industrial applications. Due to its corrosion resistance, strength, and heat resistance properties, stainless steel sheets are ideal for manufacturing processes that require a material to withstand harsh conditions, such as chemical processing, food and beverage production, pharmaceutical manufacturing, and automotive manufacturing. Stainless steel sheets can be formed, cut, welded, and machined to suit specific manufacturing requirements, making them a popular choice in the industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

430 201 202 304 304l 316 316l 321 310s 309s 904l Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords