Branded Green Colour Rubber Adhesive Masking Tape NZ

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 roll

- Supply Capability:

- 20000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General purpose of Green Colour Rubber Adhesive Masking Tape

1) good adhesive

2) good flexibility

3) No residual left

4) Different sizes are available

Feature of Green Colour Rubber Adhesive Masking Tape

general purpose masking tape, adhesive tape, paper tape.

1) good adhesion. 2) good flexibility.

-General purpose masking tape is made of crepe paper coated with natural rubber adhesives.

-It is designed for interior paint masking, light-duty packaging, holding, bundling, splicing and packaging.

-Practical for construction, building, home, office or industrial applications.

-Jumbo roll, log roll and cut roll are available.

-The width of jumbo roll is from 980mm - 1250mm

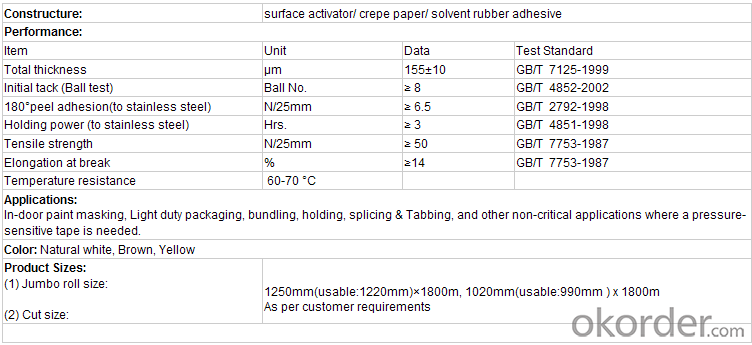

Specifications

Advantages of Green Colour Rubber Adhesive Masking Tape:

Different temperature resistance with good adhesion

High tensile strength, good resistance of damage, no residue, eco-friendly

Accept custom design

SGS, ISO, BV, CTI certificates approved

Professional teamwork for orders

No.267 on the 2014 Fortune Global 500

Professional manufacturer with 31 years experiences of adhesive tapes

Special size, color can be made according to customer's requirement.

Our Services

Your inquiry related to our product & price will be replied within 24 hours.

Well-trained & experienced staff can answer all your inquiries in English or other language

Your business relationship wit us will be confidential to any third party

Good after-sale service offered please free feel to contact us for more information

FAQ

Q 1: Do you have any MOQ of Wonder Masking Tape?

A: Yes, according to the size you need.

Q 2: What is the delivery time?

A: Sample time 7 days, 30 days for the mass production.

Q 3: Can we put our logo on the products?

A: Yes, welcome.

Q 4: How should I pay for you if I place order to you?

A: Usually, 30% T/T deposit in advance, 70% balance against the copy of B/L.

- Q: Can packaging tape be used for sealing plastic wrap?

- No, packaging tape is not typically used for sealing plastic wrap. Packaging tape is designed to adhere to cardboard and other surfaces, providing a secure seal for packages. On the other hand, plastic wrap is a thin, transparent film used to cover and protect food or other items. It is typically sealed by pressing the edges together or using a specialized plastic wrap cutter. While packaging tape may provide a temporary seal, it is not designed for use with plastic wrap and may not provide a secure or long-lasting seal. It is recommended to use the appropriate method for sealing plastic wrap, as specified by the manufacturer.

- Q: Can packaging tape be used for sealing office supplies or stationery?

- Yes, packaging tape can certainly be used for sealing office supplies or stationery. It is a versatile adhesive tape that is commonly used for sealing boxes and packages. However, when using packaging tape for sealing smaller items like office supplies or stationery, it is important to consider the size and weight of the item. If the item is lightweight and the packaging tape is not too wide or bulky, it can be a convenient and effective option for sealing. However, for smaller items, it may be more suitable to use other types of tape, such as clear tape or double-sided tape, which are specifically designed for sealing stationery and office supplies.

- Q: What are the common sizes and lengths of packaging tape rolls?

- The common sizes and lengths of packaging tape rolls vary depending on the specific needs and preferences of individuals or businesses. However, there are a few standard sizes and lengths that are commonly found in the market. The most common width for packaging tape rolls is 2 inches (or approximately 5 centimeters). This width is suitable for most general packaging purposes, providing a good balance between adhesion strength and ease of application. In terms of length, packaging tape rolls usually come in various options ranging from 55 yards (or approximately 50 meters) to 110 yards (or approximately 100 meters). The 55-yard length is often considered standard and is widely available, while the 110-yard length is commonly referred to as a "jumbo" roll and is preferred by those who require larger quantities of tape or frequently engage in extensive packaging tasks. It's worth noting that some manufacturers may offer packaging tape rolls with different dimensions, catering to specific needs. For instance, there may be narrower or wider tapes available, such as 1.5 inches or 3 inches, to accommodate specific packaging requirements. Ultimately, the choice of size and length of packaging tape rolls depends on the volume of packaging tasks, the nature of the items being packaged, and personal preferences. It is advisable to consider the specific needs and evaluate the best option accordingly.

- Q: What are the benefits of using silent packaging tape?

- Silent packaging tape offers several benefits including noise reduction during packaging, increased productivity due to minimized distractions, improved customer satisfaction by avoiding noisy packaging, and a more pleasant work environment for employees.

- Q: Is packaging tape resistant to chemicals or solvents?

- Generally, chemicals and solvents do not pose a threat to packaging tape. Packaging tapes are typically composed of materials like polypropylene or polyvinyl chloride (PVC), which possess excellent chemical resistance. These materials are specifically engineered to endure exposure to a broad array of chemicals and solvents commonly found in industrial or commercial settings. Nevertheless, it is crucial to acknowledge that the resistance of packaging tape may differ depending on factors such as the brand, type, and quality of the tape. Consequently, it is advisable to review the product specifications or seek guidance from the manufacturer to obtain detailed information regarding the chemical resistance of a particular tape.

- Q: Can packaging tape be used for sealing wooden crates?

- Yes, packaging tape can be used for sealing wooden crates. It provides a strong and secure bond, ensuring that the crate remains sealed during transportation or storage. Packaging tape is designed to adhere to various surfaces, including wood, making it an effective choice for sealing wooden crates. However, it is important to consider the weight and size of the crate before solely relying on packaging tape. For heavier or larger crates, it may be necessary to reinforce the seal with additional methods such as nails or screws.

- Q: Is packaging tape resistant to extreme pressure or weight?

- Packaging tape is designed to provide a strong and secure seal for packages, but its resistance to extreme pressure or weight can vary depending on the specific type and quality of the tape. Generally, packaging tapes are made from durable materials like polypropylene or polyester that can withstand typical handling and transportation pressures. However, it is important to note that packaging tape may not be able to withstand extremely heavy loads or excessive pressure. In such cases, it is recommended to reinforce the tape with additional layers or use specialized heavy-duty tapes that are specifically designed for high-pressure or weight-bearing applications.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is typically designed to be easily removed without causing any harm to surfaces. However, the ease of removal can vary depending on several factors, including the type and quality of the tape, the surface it is applied to, and how long it has been in place. Most packaging tapes are created to stick firmly to surfaces during transportation or storage, ensuring that the package remains sealed and secure. Nevertheless, they are also formulated to be peeled off easily when necessary, without leaving any residue or causing damage. In most situations, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is generally developed to strike a good balance between sticking power and ease of removal. This allows for effortless removal without the need for excessive force or any sticky residue. However, there may be instances where the tape might be more challenging to remove, particularly if it has been in place for a long time or exposed to extreme temperatures. In such cases, using heat, such as a hairdryer, to soften the adhesive can be helpful, making it easier to peel off. It is important to note that the ease of tape removal can also be influenced by the surface it is applied to. Smooth and non-porous surfaces like glass or metal are generally easier to clean without causing any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to prevent any potential damage. In conclusion, while packaging tape is generally designed to be easily removed without causing damage, it is essential to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

- Q: Are there any safety precautions to consider when using packaging tape?

- Yes, there are a few safety precautions to consider when using packaging tape. First, always use caution when handling the tape dispenser to avoid accidental cuts or injuries. Ensure that the area where you are using the tape is clear of any obstacles or potential tripping hazards. It is also important to store the tape in a safe place, away from heat sources or direct sunlight, as excessive heat can cause the tape to lose its adhesive properties. Lastly, be mindful of the weight and size of the package you are sealing, as using insufficient tape can cause the package to come apart during transportation.

- Q: Can packaging tape be used for sealing foam?

- Yes, packaging tape can be used for sealing foam. Packaging tape is commonly used for sealing boxes and packages, but it can also be used effectively to seal foam. When using packaging tape to seal foam, it is important to ensure that the tape is securely adhered to the foam surface to create a tight seal. This can be achieved by applying pressure to the tape after it has been applied. Additionally, it is recommended to use a tape that is specifically designed for sealing foam, as these tapes often have stronger adhesive properties and are more resistant to temperature changes and moisture. Overall, packaging tape can be a convenient and effective option for sealing foam.

Send your message to us

Branded Green Colour Rubber Adhesive Masking Tape NZ

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 roll

- Supply Capability:

- 20000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords