Custome Packaging Tape Uline - BOPP Bag Sealing Tape for Various Industries

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1 x 20FCL roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

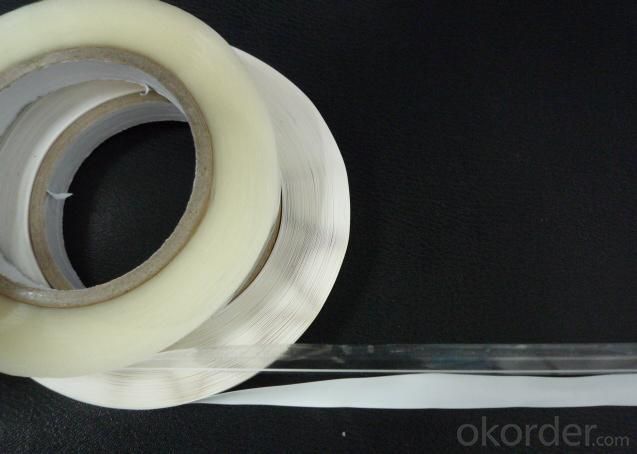

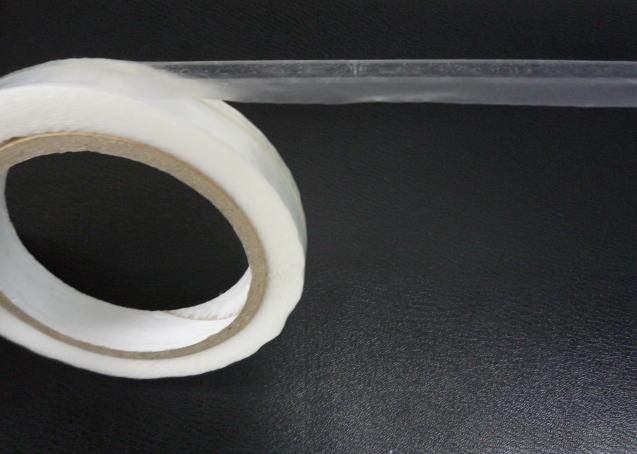

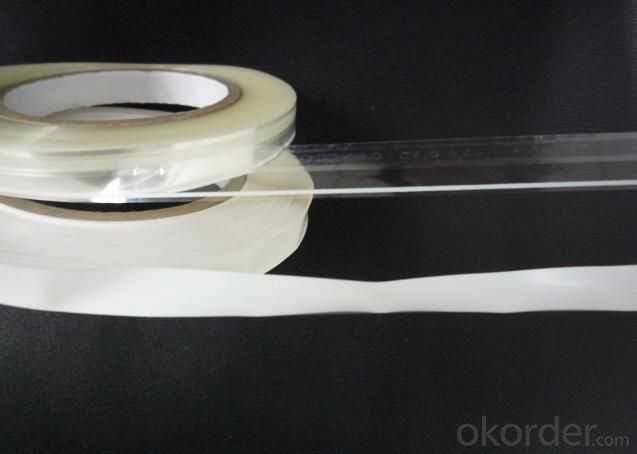

General Information Of Packing Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

Suitable for sealing plastic bags such as OPP or PP .PE materials.

Reusable, no peel off of adhesive, no residue.

It does not react chemically with the contents of the bags to color changes etc.

Name Bag Sealing Tape

Item No BG-15P

Carrier PET film

Release Liner PE Film

Adhesive Acrylic Adhesive

Release Liner width 13/14mm

Carrier Width 6mm

AB Side Coating Width 4mm/7mm (middle glue)

Packing Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

Core I.D.: 3” (76mm?1)

Jumbo Roll:1280mm x 4000m

Cut Roll: As per customer’s requirements

Application Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

Carton sealing & packing, Light duty packaging, bundling, holding, and other office & household use.

Service Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

We have a group of professional technicians and workers with rich experience, who are dedicated in this industry and try to offer best service to every customer. We are undertaking the idea of “reliable quality, reasonable price, and good service” to meet the needs of every customer. Your success is our goal, and your content is our hope. We keep pursuing “exact production, high-quality service”.

Handing and Storage OfBOPP Bag Sealing Tape Used For Sealing In Various Industries

Handling procedures:Caution with edge of sheet. After using this sheet, wash hands.

Storage procedures:Keep dry and cool and away from direct sunlight for quality.

Stability and Reactivity Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

Chemical Stability: Stable and non-reactivity

Conditions to Avoid: Away from high temperature

Incompatibility with various substances:specific materials/condition to avoid.

Hazardous Decomposition Products:Thermal decomposition will produce mainly C02,and slightly CO.

Hazardous Polymerization:Can not occur

Transport Information Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

Not a hazardous material for DOT shipping.

UN:None

Packaging sign:According to the buyer

Packaging Category:No information found/According to the buyer.

Shipping Marks: According to the buyer

Remarks Of BOPP Bag Sealing Tape Used For Sealing In Various Industries

The data above are typical results and subject to change without notice.

Tolerance: Weight and Thickness: 10%; Width: 3mm; Length: Cut Roll & Log Roll 0.3m, Jumbo Roll 0.5%.

The products should be stored at room temperature and be kept away wet and/or heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

- Q: Is packaging tape resistant to tearing or ripping?

- Yes, packaging tape is designed to be resistant to tearing or ripping. It is typically made from strong materials like polypropylene or polyester and has reinforced fibers or adhesive for added durability.

- Q: Is packaging tape resistant to mold or mildew?

- Packaging tape is generally resistant to mold or mildew. Typically, materials like polypropylene or vinyl, which do not offer a suitable environment for mold or mildew growth, are used to make most packaging tapes. These materials are impermeable and waterproof, preventing moisture from penetrating and creating conditions favorable for mold or mildew to thrive. Moreover, packaging tape often has a mold or mildew-resistant adhesive coating. Nevertheless, it is worth mentioning that if the tape is applied to a surface already contaminated with mold or mildew, it may not hinder further growth or eradicate the existing mold or mildew.

- Q: Can packaging tape be used for sealing glass jars?

- Indeed, sealing glass jars is possible with packaging tape. However, it should be noted that packaging tape is not specifically designed for this purpose and more suitable alternatives are available. While packaging tape can offer a temporary seal, it may not be as effective in preserving the freshness and airtightness of the jar's contents. Furthermore, the tape may not adhere well to glass surfaces and could peel off over time, potentially compromising the seal. For optimal results in preserving the contents of glass jars, it is recommended to utilize specialized methods and materials such as rubber gaskets, metal lids with screw caps, or heat-sealing techniques.

- Q: Can packaging tape be used for sealing chemical or hazardous material containers?

- No, packaging tape is not suitable for sealing chemical or hazardous material containers as it is not designed to withstand the potential leaks or spills that may occur. Specialized tapes or sealing methods should be used to ensure proper containment and safety.

- Q: How does packaging tape differ from masking tape?

- Packaging tape and masking tape are distinct types of tapes serving different purposes and possessing unique traits. Specifically intended for sealing and securing packages or boxes, packaging tape finds common use in the shipping and packaging industries. It is typically constructed from robust and long-lasting materials like polypropylene or PVC, ensuring exceptional adhesion and resistance against tearing or splitting. Its notable high tensile strength guarantees the package remains securely sealed during transit or storage. Moreover, packaging tape generally boasts a potent adhesive that adheres well to various surfaces, including cardboard, plastics, and metals. It is available in different widths and lengths to accommodate diverse packaging requirements. In contrast, masking tape primarily finds application in painting and DIY projects. Composed of a thinner and less resilient material, such as crepe paper, it possesses a less aggressive adhesive in comparison to packaging tape. The primary objective of masking tape is to establish clean, straight lines and safeguard surfaces from paint or other liquids during painting tasks. Masking tape can be effortlessly applied and removed without leaving any residue or causing damage to the surface. Furthermore, it is recognized for its ability to conform to uneven surfaces, enabling precise masking and detailing work. To summarize, packaging tape is designed for secure sealing and packaging of boxes and packages, whereas masking tape is primarily utilized for painting and surface protection. Packaging tape is stronger, more durable, and possesses a more potent adhesive, whereas masking tape is thinner, more flexible, and can be effortlessly removed without leaving any residue.

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Yes, packaging tape can be used for sealing protective packaging materials like bubble wrap. It provides a secure and effective way to seal the packaging, ensuring that the contents remain protected during transportation or storage.

- Q: What are the tapes for packing tape?

- Double sided tape writing, leather tape, textured adhesive tape, high temperature resistant double sided adhesive tape, industrial adhesive tape

- Q: What are the different types of packaging tape available?

- There are several different types of packaging tape available, including transparent tape, brown or tan tape, reinforced tape, water-activated tape, and duct tape. Each type of tape has its own unique properties and is designed for specific packaging needs and applications.

- Q: Is packaging tape resistant to UV rays?

- Packaging tape is typically resistant to UV rays, as it is commonly composed of materials such as polypropylene or polyethylene that possess innate UV radiation resistance. Consequently, the tape remains intact and adhesive when exposed to sunlight or other UV sources. Nonetheless, it is crucial to acknowledge that prolonged UV exposure may gradually degrade the tape. For optimal durability, it is advisable to store and employ packaging tape in a cool, dry location, avoiding direct sunlight whenever feasible.

- Q: Is packaging tape waterproof?

- Yes, packaging tape is typically waterproof. It is designed to be resistant to moisture and can provide a strong seal, preventing water from seeping into the package. However, it is important to note that the level of waterproofing may vary depending on the quality and type of packaging tape used. Some tapes may provide a more secure seal than others, so it is always recommended to choose a tape specifically designed for packaging and sealing purposes.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | Southeast Asia; South America; Eastern Europe; North America; Northern Europe; South Asia; Western Europe; Africa; Mid East |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 10%-20% |

| No.of Employees in Trade Department | 11-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 600 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | produce single sided tapes,double sided tapes, masking tape, Opp tape |

| Product Price Range | High; Average |

Send your message to us

Custome Packaging Tape Uline - BOPP Bag Sealing Tape for Various Industries

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1 x 20FCL roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords