Blacked Coated Hot Rolled High Carbon Seamless Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Blacked Coated Hot Rolled High Carbon Seamless Steel Pipe

1.Structure of Hot Rolled High Carbon Seamless Steel Pipe:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2.Main Features of the Hot Rolled High Carbon Seamless Steel Pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3.Hot Rolled High Carbon Seamless Steel Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4. Packing and Delivery:

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 50-60days after received 30%TT or Original LC |

5. FAQ of Hot Rolled High Carbon Seamless Steel Pipe

A. How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

B. How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

C. Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

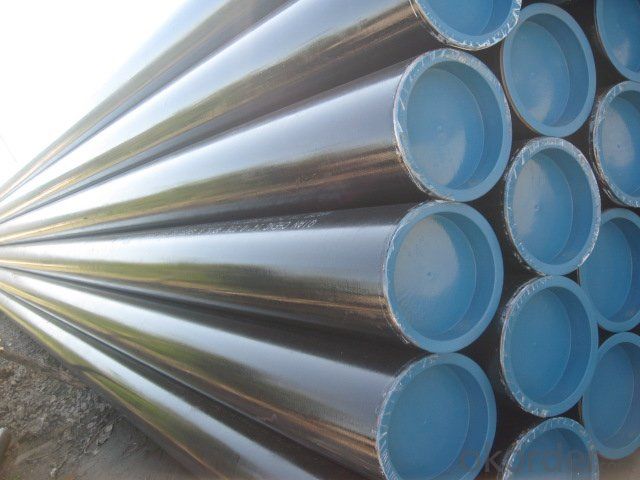

6.Hot Rolled High Carbon Seamless Steel Pipe Images:

7. Company Information:

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. In line with the business, CNBM International launched E-business platform Okorder.com.Our goal is to transform CNBM International into the global leading brand in building materials industry within 3 to 5 years through innovation and reform, by strengthening the overall management of supply chain, developing and cultivating both domestic and overseas market, improving the procedure and information system, enhancing the ability to organize resources and to provide value-added services under a professional team and a learning organization.

- Q: How are steel pipes protected against rusting?

- Steel pipes are protected against rusting through a process called corrosion protection. There are several methods employed to prevent rust formation on steel pipes, including: 1. Coatings: One common method is applying various coatings to the surface of the steel pipes. These coatings act as a barrier, preventing oxygen and moisture from reaching the metal surface and initiating the rusting process. Coating options include epoxy, polyethylene, zinc, or even a combination of these materials. 2. Galvanization: Galvanizing steel pipes involves immersing them in a bath of molten zinc. This process creates a protective layer of zinc on the surface of the pipes which acts as a sacrificial barrier. If any small areas of the pipe surface are exposed, the zinc coating will corrode instead of the steel, providing ongoing protection against rust. 3. Cathodic Protection: This method utilizes an electrical current to protect the steel pipes. By connecting the pipes to a sacrificial anode, usually made of zinc or magnesium, the anode will corrode instead of the steel pipes when exposed to moisture and oxygen. This process is commonly used in underground or underwater applications. 4. VCI (Vapor Corrosion Inhibitor) Technology: VCI technology involves the use of chemical compounds that release a vapor that protects the steel pipes from rusting. These compounds form a thin layer on the surface of the pipes, inhibiting the corrosion process by neutralizing oxygen and moisture. 5. Regular Maintenance: In addition to the above methods, regular inspection and maintenance are crucial to prevent rust formation on steel pipes. This includes cleaning the pipes, removing any accumulated debris or corrosive substances, and repairing any damaged coatings or protective layers. Overall, these methods of corrosion protection effectively safeguard steel pipes from rusting, ensuring their longevity and durability in various industrial, commercial, and residential applications.

- Q: What does GALV mean in a steel tube?

- GALV is the abbreviation of English galvanized (Galvanized), which means galvanized steel pipe.

- Q: What is the average lifespan of a steel pipe?

- The average lifespan of a steel pipe can vary depending on various factors such as its quality, usage conditions, maintenance, and exposure to external factors. However, on average, a properly installed and maintained steel pipe can last anywhere from 20 to 100 years or more.

- Q: How are steel pipes measured and specified?

- Steel pipes are measured and specified based on their diameter (nominal pipe size or NPS) and wall thickness (schedule or SCH). The NPS represents the internal diameter of the pipe, while the SCH indicates the thickness of the pipe walls. These measurements are crucial for ensuring proper compatibility and functionality in various applications, such as plumbing, construction, and industrial processes.

- Q: What are the alternatives to steel pipes for various applications?

- Some alternatives to steel pipes for various applications include PVC (polyvinyl chloride) pipes, copper pipes, aluminum pipes, and fiberglass pipes. Each alternative has its own advantages and disadvantages, such as cost, durability, and resistance to corrosion, which make them suitable for specific applications.

- Q: Are steel pipes suitable for underground irrigation pumping?

- Indeed, steel pipes prove to be a fitting option for underground irrigation pumping. Renowned for their robustness and resilience, steel pipes present themselves as an optimal selection for subterranean utilities. They boast the capacity to endure substantial pressure, ward off corrosion, and remain less susceptible to soil shifting or fluctuations in temperature. Moreover, steel pipes exhibit a lengthier lifespan when juxtaposed with alternative materials, thereby mitigating the necessity for frequent replacements. However, it remains imperative to guarantee meticulous coating or lining of the steel pipes to avert corrosion and to consistently examine and uphold them for their continued efficacy and durability.

- Q: How are steel pipes used in fire protection systems?

- Fire protection systems rely on the inclusion of steel pipes, which serve as an essential component for the distribution of water and fire suppressants within buildings. These pipes are renowned for their robustness, longevity, and ability to endure extreme temperatures, rendering them optimal for withstanding the harsh conditions associated with fires. Within fire protection systems, steel pipes are commonly utilized to establish an interconnected network of pipes responsible for supplying water to sprinkler heads or fire hydrants throughout a building. This network guarantees that water is readily accessible to suppress or extinguish fires during emergencies. One of the primary advantages of steel pipes in fire protection systems is their capacity to withstand the elevated pressure and flow rates necessary for effective fire suppression. Steel pipes can handle forceful water flow with ease, enabling prompt and efficient distribution of water to affected areas, thereby aiding in the control and extinguishing of fires in the shortest possible time. Additionally, steel pipes possess an inherent resistance to corrosion, a crucial attribute for preserving the integrity of fire protection systems over time. Corrosion has the potential to weaken pipes, leading to leaks or complete failure, which can prove catastrophic during a fire incident. However, steel pipes possess an extended lifespan and require minimal maintenance when compared to other pipe materials, ensuring the longevity and dependability of the system for many years to come. Moreover, steel pipes are frequently selected for use in fire protection systems due to their fire-resistant properties. Steel inherently possesses the ability to withstand high temperatures without deformation or compromising its structural integrity. This characteristic is of utmost importance in fire protection systems, as it enables the pipes to remain intact and continue delivering water even amidst a fire, ensuring the safety of occupants and minimizing damage to the building. In conclusion, steel pipes hold a pivotal role in fire protection systems by guaranteeing the reliable and efficient distribution of water or fire suppressants. Their strength, durability, resistance to high temperatures, and corrosion resistance make them the ideal choice for effectively combating fires and safeguarding lives and property.

- Q: How do you calculate the stress in a steel pipe?

- To calculate the stress in a steel pipe, you need to determine the applied force or load acting on the pipe and divide it by the cross-sectional area of the pipe. This will give you the stress value, which is typically measured in units of force per unit area (such as pounds per square inch or pascals).

- Q: What's the difference between No. 20 steel pipe and 27SiMn Steel Pipe?

- Cold plastic deformation and for bending, rolling, bending and hammer arch processing, arc welding and contact welding welding performance is good, when the thickness is small, prone to strict requirement of shape crack or complex shape parts. The cold or normalizing condition of cutting is better than that of annealing. It is generally used to make the material with little force and high toughness.

- Q: How do steel pipes handle chemical substances?

- Steel pipes are highly resistant to chemical substances due to their inherent strength and durability. They can effectively handle a wide range of chemical substances without corroding or degrading. Additionally, steel pipes can be further protected by coatings or linings to enhance their resistance to specific chemicals.

Send your message to us

Blacked Coated Hot Rolled High Carbon Seamless Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords