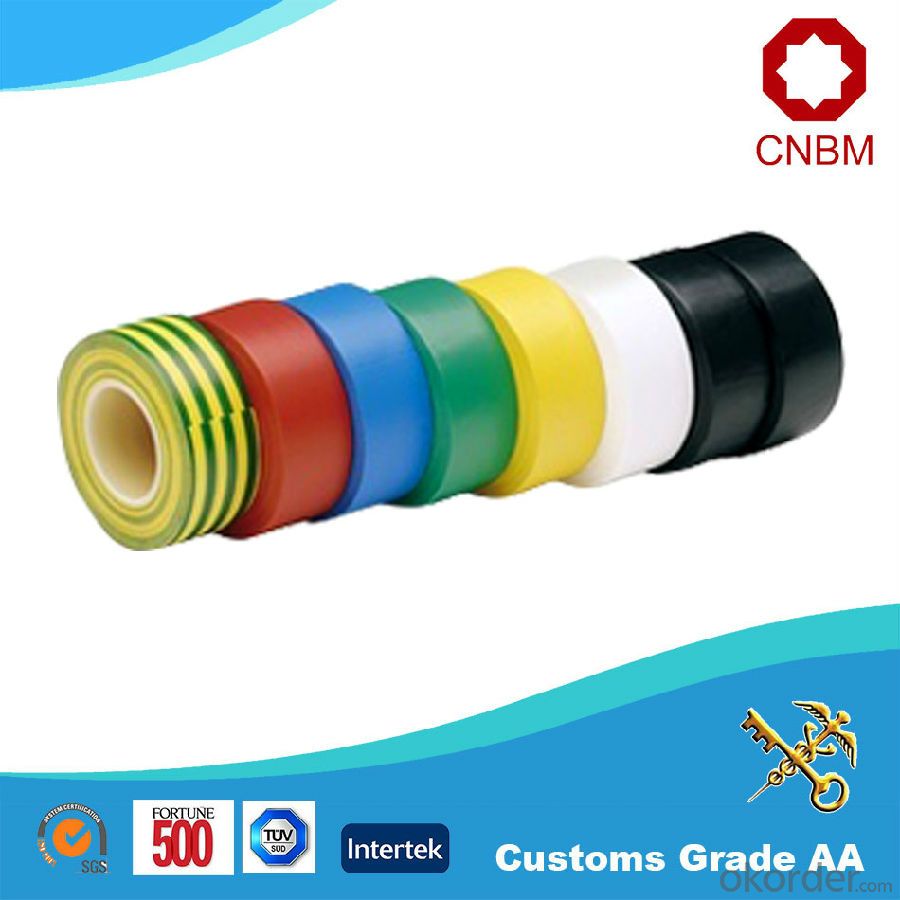

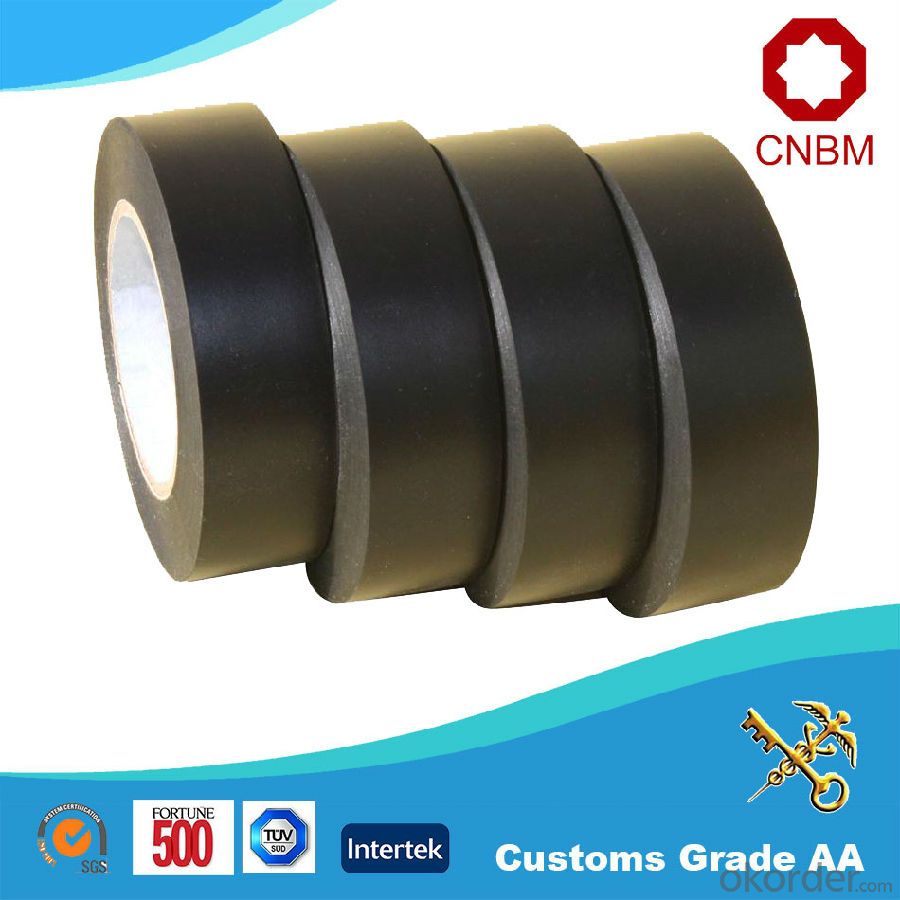

Black Vinyl Packaging Tape with Strong Adhesion PVC Wire Harness Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wire Harness Tape PVC Strong Adhension Cheap

1. Structure of Wire Harness Tape Description

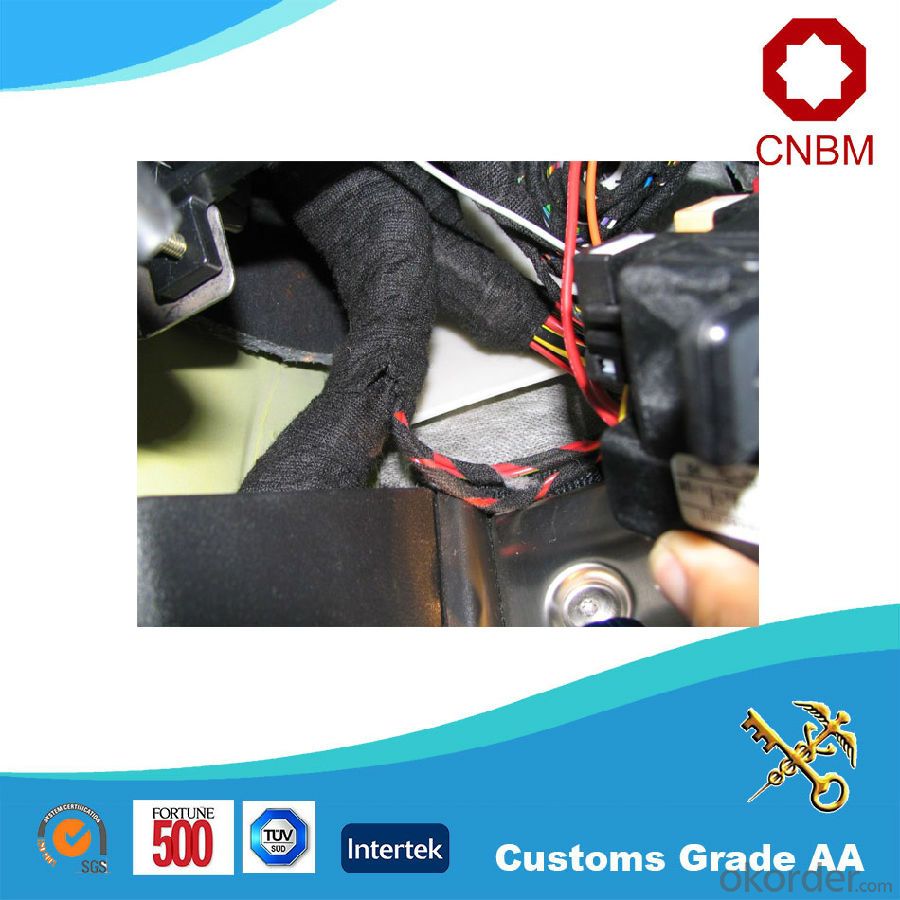

Wire Harness Tape is of PVC film as the carrier, coating with natural rubber. Wire Harness Tape: widely used as permanent wrapping on cables and wiring harnesses for automobile.

2. Main Features of the Wire Harness Tape

High abrasion resistance

Moisture resistant

High adhesive force

Burning-resistance

High tear resistance and stability

Safety and environmental friendly

3. Wire Harness Tape Images

4. Wire Harness Tape Specification

Item No. | Thickness (micron) | Adhesion to steel (N/cm) | Tensile Strength (N/cm) | Elogation (%) | Teperature Resistance (DC) | Flame Resistance (S) |

PW-11 | 110 | 1.2 | 15 | 150 | 80 | <2< span=""> |

PW-12 | 120 | 1.2 | 16 | 150 | 80 | <2< span=""> |

PW-13 | 120 | 1.2 | 20 | 180 | 80 | <2< span=""> |

PW-15 | 120 | 1.2 | 25 | 200 | 80 | <2< span=""> |

5. FAQ

Q1. Why choose us?

World Top 500 Enterprise

Quality guarantee with third party certification

OEM service, supported by strong R&D team

One-step service: transportation, capital etc.

A short lead time

Q2. What is the working environment?

Working temperature: from -18°C to +80°C. It is specially conceived for professional electrical insulating applications where environmental safety is concerned.

Q3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do I prevent packaging tape from wrinkling?

- To prevent packaging tape from wrinkling, make sure to apply it smoothly and evenly, without any folds or creases. Start by holding the tape at a slight angle and pressing it firmly onto the surface, while gradually unrolling it. Avoid tugging on the tape too forcefully, as this can cause it to wrinkle. Additionally, using a good quality tape dispenser or a handheld tape gun can help ensure a smooth application.

- Q: Can packaging tape be used for other purposes besides packaging?

- Yes, packaging tape can be used for other purposes besides packaging. It can be used for sealing envelopes, securing loose items, repairing torn paper or books, creating temporary labels, organizing cables, and many other miscellaneous tasks.

- Q: Is packaging tape safe for use on children's toys or products?

- Packaging tape is not recommended for direct use on children's toys or products. While packaging tape is commonly used for sealing and securing packages, it is not designed or tested for contact with children's skin or for use on items that may come into direct contact with their mouths or eyes. Children's toys and products are subject to specific safety regulations and guidelines to ensure they are safe for use and do not pose any harm to children. It is important to follow the manufacturer's instructions and use appropriate materials that are specifically designed for children's toys and products, such as non-toxic adhesives or child-safe tapes, to ensure the safety of children.

- Q: Does packaging tape come in different materials for specific applications?

- Yes, packaging tape does come in different materials for specific applications. These materials include polypropylene, PVC, paper, and filament tape. Each material has unique properties that make it suitable for various purposes such as sealing lightweight packages, securing heavy boxes, or providing extra strength and tear resistance.

- Q: Can packaging tape be used for sealing cardboard boxes?

- Yes, packaging tape is commonly used for sealing cardboard boxes as it provides a strong and secure bond.

- Q: Is packaging tape safe to use on painted furniture?

- Yes, packaging tape is generally safe to use on painted furniture. It is designed to adhere to various surfaces, including painted surfaces, without causing damage or leaving residue when properly applied and removed. However, it is always recommended to test a small, inconspicuous area first to ensure compatibility and to handle the tape with care to avoid any potential paint or finish peeling.

- Q: Can packaging tape be used for sealing pet food or treats?

- Yes, packaging tape can be used for sealing pet food or treats. It provides a strong and secure seal to keep the contents fresh and protected. However, it is important to ensure that the tape used is safe for pets, meaning it should be non-toxic and not contain any harmful substances that could potentially be ingested by the animals. It is recommended to use pet-safe packaging tape specifically designed for sealing pet food or treats, as it meets the necessary safety requirements and regulations.

- Q: Can packaging tape be used for other purposes?

- Yes, packaging tape can certainly be used for other purposes beyond its primary use of sealing packages. Due to its strong adhesive properties and durability, it can be used for various other applications. One common alternative use of packaging tape is for organizing and bundling items together. Whether it's sorting cables and cords, securing loose items, or grouping similar items, packaging tape can effectively keep things neatly organized. It can also be used to secure items to walls or surfaces temporarily, such as posters or decorations, without causing any damage. Additionally, packaging tape can be utilized for crafting and DIY projects. Its adhesive nature makes it a great material for creating temporary or permanent bonds between different materials. It can be used to repair torn papers, create labels or tabs, or even make custom stickers. Its versatility and availability in different widths and lengths make it a handy tool for various creative endeavors. Moreover, packaging tape can be utilized for household fixes and repairs. From mending broken items to reinforcing weak joints, the strong adhesive properties of packaging tape can provide a quick and temporary solution. It can also be used to seal minor leaks or cracks temporarily until a proper repair can be made. In conclusion, while packaging tape is primarily designed for sealing packages, its strong adhesive properties and versatility make it suitable for various other purposes. Whether it's organizing, crafting, or quick fixes, packaging tape can be a useful tool to have on hand.

- Q: What are the considerations for using packaging tape on plastic packaging materials?

- When working with plastic packaging materials and using packaging tape, it is essential to keep several important factors in mind. These factors include: 1. Adhesive Compatibility: Ensuring that the adhesive used in the packaging tape is compatible with the specific type of plastic material is crucial. Different plastics have different surface properties, and they may require different adhesive formulations to ensure proper bonding. For instance, low surface energy plastics like polyethylene may necessitate a tape with a specially designed adhesive for such surfaces. 2. Strength and Durability: Plastic packaging materials come in varying thicknesses and strengths. When choosing packaging tape, it is important to consider the strength and durability required for the specific plastic material being used. The tape should be strong enough to securely hold the packaging together without tearing or breaking, thus maintaining the package's integrity during handling and transportation. 3. Temperature Resistance: Plastic packaging materials can be sensitive to temperature changes. If the package is exposed to extreme temperatures, such as heat or cold, the packaging tape should be capable of withstanding these conditions without losing its adhesive properties. Certain plastic materials may also shrink or expand due to temperature changes, which can impact the tape's adhesion. Therefore, it is important to select a tape suitable for the expected temperature range. 4. Residue and Damage: Some packaging tapes may leave behind adhesive residue or cause damage when removed from plastic packaging materials. This can pose a problem if the packaging needs to be reused or if the plastic material is susceptible to damage. By choosing a packaging tape that is designed to be easily removable or leaves minimal residue, these concerns can be mitigated. 5. Regulatory Compliance: Depending on the industry or product being packaged, there may be specific regulations and standards that must be followed. It is important to ensure that the packaging tape used complies with any applicable regulations, such as food safety standards or environmental requirements. By taking these factors into consideration, one can select the appropriate packaging tape that will effectively adhere to plastic packaging materials while also providing the necessary strength, durability, temperature resistance, and compliance with regulations.

- Q: How do I prevent packaging tape from becoming too loose?

- Here are some helpful suggestions for preventing packaging tape from becoming loose: 1. Opt for high-quality packaging tape: Invest in packaging tape that boasts a strong adhesive. Inferior quality tapes tend to lose their stickiness quickly, resulting in loose packaging. 2. Ensure cleanliness and dryness of surfaces: Prior to applying the tape, make sure that the surfaces are clean and dry. Dust, moisture, or oil can weaken the adhesive and cause the tape to loosen. 3. Apply firm pressure: When sealing a package, exert firm pressure while affixing the tape onto the surface. Be sure to run your hand or a flat object along the length of the tape to ensure proper adhesion. 4. Utilize overlapping tape: Instead of using only a single strip of tape, overlap it by a few inches. This overlapping technique provides added strength and diminishes the likelihood of the tape becoming loose. 5. Avoid extreme temperature fluctuations: Extreme temperature changes can adversely affect the adhesive properties of packaging tape. Refrain from storing packages in areas with high humidity or extreme temperature variations, as this can cause the tape to loosen. 6. Strengthen with extra tape: If you are sealing a heavy or bulky package, contemplate reinforcing it with additional tape. Apply extra strips of tape across the sides or diagonally to provide supplementary support and minimize the risk of the tape coming loose. 7. Properly store packages: When storing packages, ensure they are stacked correctly and not subjected to excessive pressure or weight. Inadequate storage conditions can cause the tape to loosen over time. By adhering to these recommendations, you can effectively prevent packaging tape from becoming too loose, thereby guaranteeing that your packages remain securely sealed during transit or storage.

Send your message to us

Black Vinyl Packaging Tape with Strong Adhesion PVC Wire Harness Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords