Quick Details

Material: 100% PP

Supply Type: Make-to-Order

Type: Mesh Fabric

Pattern: Coated

Coated Type: HDPE Laminated

Style: Plain

Width: <span class="attr-value" title="57/58"" style="margin: 0px; padding: 0px; border: 0px; font-family: inherit; font-size: inherit; font-style: inherit; font-variant: inherit; font-weight: inherit; line-height: inherit; vertical-align: baseline; word-wrap: break-word;">57/58"

Technics: Woven

Feature: Waterproof, Anti-Static, Tear-Resistant, Blackout, Shrink-Resistant

Use: Bag, Military, Tent, Curtain, Industry, Toy

Certification: Oeko-Tex Standard 100

Yarn Count: 650D

Weight: 50-180GSM

Density: 7*7,9*9,11*11

Model Number: Multiple

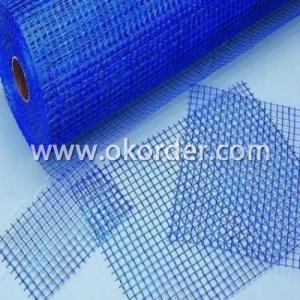

Material: PE

Width: 2-10m

Weight: 60-160GSM

Colour: various colours

Sizes: as required