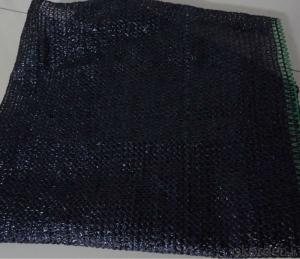

ISO Standard PE Tarpaulin for Waterproof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PE Tarpaulin

Company and Product Introduction

Our company was founded in 1984, with production area more than 100000m2, more than 300 production lines, including 10 sets drawing machine, 250sets woven machine, 20 sets coating machine, 20 printing machine.

We specializing in producing and exporting tarpaulin, including PE tarpaulin, PP tarpaulin, PVC tarpaulin, Mesh tarpaulin, Camouflage tarpaulin, and special customized tarpaulin.

Feature of Tarpaulin

-Waterproof

-Sun block

-Freezing-resistant

-Anti-aging

-corrosion-resistant

-Portable, easy folding and durable

Application of Tarpaulin

-Make shock proof shed

-Greenhouse

-Woven bag

-Grass prevention cloth

-Furniture cover

-Insulation quilt

-Truck cover

-Also widely used in shipyard, oil field, industrial and mining area, petroleum industrial, construction site, etc.

Tarpaulin technical data

Material | HDPE woven fabric with LDPE coating in both sides |

Density | 6*6~16*16 mesh |

Weight | From 50g/m2 up to 300g/m2 |

Color | Blue/ Grey/ Green/ White/ Yellow/ Red, any color is avalible |

As customer required | |

Tarpaulin Roll Size | 100m per roll or as customers’ requirement |

Tarpaulin Sheet Size | Regular size(m*m): 2*3, 3*4, 3*5, 4*5, 4*6, 5*8,6*8,6*10,10*50, or as customers’ requirement |

Package | 1.Tarpaulin roll is packed on paper coil, packed by tarpaulin same with inner products. 2.Tarpaulin sheets are packed in a bale every 5sheets or as customers’ requirement. Carton packing is also available. |

Container Loading | 1. Tarpaulin rolls: 20GP can load 17 tons. 2. Tarpaulin sheets in bale packing: 20GP can load 10ton, 40HQ can load 25 tons. 3. Carton packing: 20GP can load 8 tons, 40HQ can load 22 tons. |

FAQ:.

1. What’s the payment term?

TT: 50% before production, 50% before shipment.

Or LC at sight.

2. Can you provide free samples?

Yes, we support you with free of charge samples, you’ll just need to pay for the express cost.

3. What’s your leading time?

For regular items, 2~3 days will finish one 40HQ. For special items, 7~15days will finish one 40HQ.

4. Will you support factory inspection and products inspection before shipment?

Yes, warmly welcome you to visit our factory and inspect products quality before shipment.

- Q: What kind of plastic is the bumper of the car made of?

- At present the domestic automobile bumper is generally used (modified) toughened polypropylene (PP) material as raw material injection molding polypropylene (propylene) - Poly (commonly known as PP plastic material), has a high melting point (up to 167 DEG C), heat density (0.90g/cm3), is a kind of general plastic in the light, there is the high corrosion resistance (tensile strength 30MPa), strength, rigidity and the transparency of its products are relatively well characterized, disadvantages are poor low temperature resistance (by impact PP copolymer, Styrene Elastomer and polyolefin rubber modified materials, 3 kinds of blend composition with high rigidity, impact resistance, scratch and coating, injection molding bumper after loading, 8 km/h impact fragmentation, and has restored flexibility, performance and cost is decreased almost PU, 10%~20%).

- Q: What are the environmental implications of using plastic in automotive products?

- The environmental implications of using plastic in automotive products are significant. Plastic production contributes to greenhouse gas emissions and relies heavily on fossil fuel extraction. Additionally, the disposal of plastic products, such as car parts and interior components, often leads to pollution and long-lasting environmental degradation. Plastic waste can end up in landfills, oceans, or incinerators, further exacerbating the problem. Moreover, the breakdown of plastic into microplastics can harm ecosystems and pose risks to wildlife and human health. Overall, reducing the use of plastic in automotive products is crucial for mitigating environmental impact and promoting sustainability.

- Q: How do automotive plastic products contribute to improved resistance to electromagnetic interference?

- Automotive plastic products contribute to improved resistance to electromagnetic interference by providing a shield against external electromagnetic radiation. These products are made with conductive materials or coated with conductive layers, which can absorb or reflect electromagnetic waves, reducing their impact on the electronic components in vehicles. This shielding effect prevents interference and ensures the proper functioning of sensitive electronic systems, such as communication devices, navigation systems, and safety features in automobiles.

- Q: What's the difference between a gasoline tank and a plastic car?

- Volume problem, the plastic tank must have internal / external stiffeners, so it will occupy part of the volume of fuel. The metal tank does not occupy the volume of the fuel. So, with the same external volume of the tank, the metal tank can hold more fuel.

- Q: Colorful cars are mainly made of plastic, rubber and other materials, right?

- Rubber can be divided into natural rubber and synthetic rubber in two categories:Natural rubber: cutting by rubber tree, mucilage collected out, after removing impurities, solidification, smoke, drying process, raw material and the formation of.2. synthetic rubber by-products produced by the petrochemical industry, according to the different needs of different raw material was synthesized. The properties such as: SBR, NBR, EPDM, BR, IIR, CR, Q, FKM and so on. But because of the difference in synthetic way, similar material can be divided into several different types of rubber. Through the setting of any type of rubber, rubber material can be changed into hundreds of products with demand.Natural rubber from rubber trees in tropical and subtropical regions. Because the rubber has an important role in industry, agriculture, national defense field, so it is an important strategic material, which prompted the lack of rubber resources of the country in the research and development of synthetic rubber.Two. Chemical composition of rubber

- Q: How do automotive plastic products contribute to improved resistance to fire?

- Automotive plastic products contribute to improved resistance to fire through the use of flame retardant additives in their composition. These additives help to slow down or prevent the spread of flames, thus increasing the overall fire safety of the vehicle. Additionally, automotive plastic products are designed to have high melting points, which further enhances their fire resistance.

- Q: What are the cost advantages of using automotive plastic products?

- There are several cost advantages associated with using automotive plastic products. Firstly, plastic materials are generally less expensive compared to traditional materials like metal or glass. This makes the production of automotive components and parts more cost-effective. Additionally, plastic is lightweight, which helps to reduce fuel consumption and increase overall vehicle efficiency, resulting in cost savings for the end consumer. Furthermore, plastic parts can be molded and shaped easily, reducing the need for additional finishing processes and labor costs. Lastly, plastic is resistant to corrosion and requires less maintenance, leading to lower repair and replacement expenses in the long run.

- Q: What are some examples of automotive plastic products used in body trim and moldings?

- Some examples of automotive plastic products used in body trim and moldings include bumper covers, door handles, mirror housings, fender flares, side skirts, grille inserts, and wheel arches.

- Q: What are the regulations governing the use of plastic in automotive products?

- The regulations governing the use of plastic in automotive products vary by country and region. In general, these regulations focus on ensuring the safety, reliability, and environmental sustainability of automotive plastics. They may involve standards for material composition, durability, flammability, and emissions. Additionally, some regulations target the recycling and disposal of plastic components to promote circular economy practices. It is important for automotive manufacturers to comply with these regulations to meet industry standards and ensure the overall quality of their products.

- Q: What's the coat under the headlights?

- The front and rear bumpers are made of plastic, known as plastic bumpers. The plastic bumper of a general automobile is composed of three parts: an outer plate, a buffer material and a cross beam. Wherein, the outer plate and the buffering material are made of plastic, and the cross beam is punched into a U groove by a cold rolled sheet; the outer plate and the buffering material are attached to the cross beam.

Send your message to us

ISO Standard PE Tarpaulin for Waterproof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords