Geocells Suppliers UK - Black PP Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Black PP Geogrid Description:

Black PP Geogrid is with polypropylene, high density polyethylene as raw materials, made by special extrusion, two-way stretch.It Can reduce structural fill, uniform load distribution, and has high two-way tensile modulus and tensile strength, high mechanical damage ability, endurance ability

Main Features of Black PP Geogrid :

Black PP Geogridcan be used to enhancement of permanent bearable toft including roads and railways embankment, slopes, tunnel, airfields, parks, docks and ground which cargo lays on and their main usage are as follows:

Enhance the bearing capacity of road foundation and extend the duration of roads.

Prevent road surface from collapse, crack and being dirty.

Be convenient for construction, timesaving and cut down the cost of maintenance.

Prevent tunnel from crack occurring

Further solidity slopes to proof water and soil from losses.

Reduce the surface thickness of the ground.

Consolidate the net for growing grass on the slopes so as to stabilization surrounding virescence.

Be used for artificial top net of mines instead of metal ones.

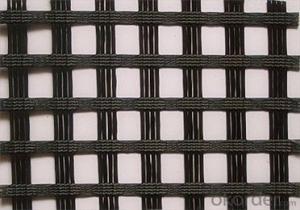

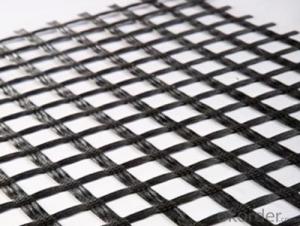

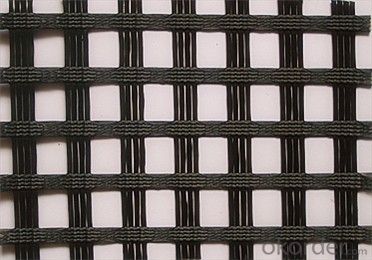

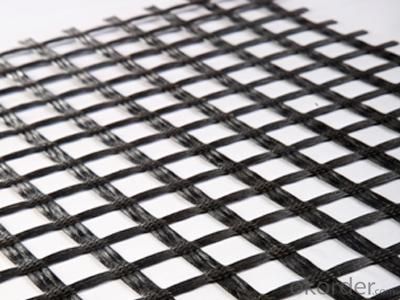

Black PP Geogrid Images

Black PP Geogrid Specification:

| Specifications | Tensile strength(KN/m) | Tensile strength at 2% elongation | Tensile strength at 5% elongation | Nomianal elongation | Products in the range of coal mine | Max peel strength at welding point | ||

| GSJ30-30 | ≥30.0 | ≥10.0 | ≥20.0 | ≤12 | Fire out time from outer flam(s) | Surface resistivity | ≥30.0 | |

| GSJ40-40 | ≥40.0 | ≥20.0 | ≥25.0 | ≤3 | <1×109 | |||

| GSJ50-50 | ≥50.0 | ≥17.0 | ≥34.0 | |||||

| GSJ60-60 | ≥60.0 | ≥22.5 | ≥40.0 | |||||

| GSJ80-80 | ≥80.0 | ≥28.0 | ≥56.0 | ≤13 | ||||

| GSJ100-100 | ≥100.0 | ≥35.0 | ≥70.0 | |||||

| GSJ120-120 | ≥120.0 | ≥60.0 | ≥90.0 | |||||

| GSJ150-150 | ≥150.0 | ≥52 | ≥104.0 | |||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geogrids be used in reinforcement of concrete structures?

- Yes, geogrids can be used in the reinforcement of concrete structures. Geogrids are high-strength synthetic materials that are commonly used to enhance the stability and strength of various civil engineering projects, including concrete structures. They are typically embedded within the concrete to provide additional tensile strength and prevent cracking or failure. Geogrids are particularly effective in applications where there is a need for increased load-bearing capacity, such as road and bridge construction.

- Q: What does the geotextile 200# mean?

- Geotextile is made of synthetic fiber by acupuncture or woven into a permeable geosynthetic material. The finished product is cloth, the general width of 4-6 meters, the length of 50-100 metersGeneral specifications from the arbitrary choice between 80g/ square meters ~800g/ square metersOf course, the high requirements of the occasion, there is a high weight of Geotextile

- Q: The difference between composite geomembrane and bentonite waterproof blanket

- Different waterproof performance. Composite geomembrane: composite geomembrane composite impermeable membrane is divided into one cloth and two membrane. Tensile, tearing resistance, bursting and other physical and mechanical properties of high index, the product has high strength, good elongation, deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, good performance of seepage control, etc..

- Q: Are geogrids effective in preventing soil creep?

- Yes, geogrids are effective in preventing soil creep. Geogrids provide additional reinforcement to the soil, increasing its stability and resistance to movement. They help distribute the forces acting on the soil, reducing the potential for creep and maintaining slope integrity.

- Q: How do geogrids improve the stability of railway embankments?

- Geogrids improve the stability of railway embankments by providing reinforcement and preventing soil movement. They distribute the load more evenly, reducing the potential for settlement and slope failure. Additionally, geogrids increase the bearing capacity of the embankment, enhancing its overall stability and longevity.

- Q: How do geogrids improve the load distribution in paved surfaces?

- Geogrids improve the load distribution in paved surfaces by providing reinforcement and stabilization to the base layers of the pavement. They distribute the load across a larger area, reducing the stress on the pavement and preventing cracks, rutting, and other forms of pavement distress.

- Q: What are the long-term maintenance requirements for geogrids?

- The long-term maintenance requirements for geogrids are typically minimal. Once installed, geogrids require periodic inspections to ensure they are functioning properly and to address any issues that may arise, such as soil erosion or damage to the geogrid itself. Additionally, regular maintenance of the surrounding area, such as vegetation control and debris removal, can help prolong the lifespan and effectiveness of the geogrids.

- Q: What is the road geogrid

- GeogridThe grid is made of polypropylene, polyvinyl chloride and other high molecular polymer thermoplastic or molded into a two-dimensional grid or a certain degree of three-dimensional grid screen, when used as civil engineering, known as the geogrid

- Q: How do geogrids improve the performance of reinforced slopes?

- Geogrids improve the performance of reinforced slopes by providing additional stability and strength to the soil structure. They act as a reinforcement material, increasing the tensile strength of the soil and preventing it from sliding or collapsing. The geogrids also distribute the applied loads more evenly, reducing the potential for deformation and settlement. Overall, geogrids enhance the slope's resistance to erosion, improve slope stability, and increase the longevity and durability of the reinforced structure.

- Q: What criteria should be used in the construction of Geogrid

- 1, the construction site: requirements compaction flat, horizontal, removal of the protrusion. 2, in the formation of compaction: Geogrid laying site, installation of the grid the main stress direction (longitudinal) should be perpendicular to the axis of the embankment, laying should be smooth, no wrinkles, as far as possible tension. With the plug pin and the earth pressure is fixed, the laying of the grille main stress direction is best long without joint connection between the amplitude and the amplitude of the manual banding lap, lap width not less than 10cm. If the grid is set above two layers, the seam should be staggered. After laying a large area, the overall adjustment of its flatness. When the cover of a layer of soil, not rolling before, should be used manually or machine tensioning grid, the strength should be uniform, so that the grid in the soil for the tension state. 3, the choice of packing: packing should be selected according to the design requirements. Practice has proved that, in addition to frozen soil, swamp soil, domestic waste, chalk, diatomite can be used as filler. However, the mechanical properties of gravelly soil and sandy soil are stable, and the water content is very small. Packing size should not be greater than 15cm, and pay attention to control the packing gradation, to ensure the compaction weight. 4, the packing of the paving and compaction: when the laying of the grid positioning, should be filled in a timely manner, the exposure time shall not exceed 48 hours, can also take the side of the laying of the backfill flow shop. First spread the filler at both ends, the grid will be fixed, and then to the central propulsion. Rolling sequence is the first two sides after the middle. When the roller compaction can not directly contact with the reinforced material, the non compacted reinforcement generally do not allow the vehicle to travel on the above, so as to avoid the dislocation. The degree of compaction is 20-30cm. Pressure...

Send your message to us

Geocells Suppliers UK - Black PP Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords