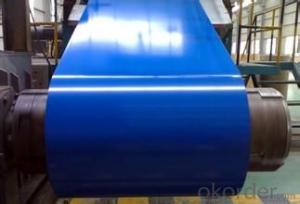

Best sell Prepainted Galvanized Steel Coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4800 PCS

- Supply Capability:

- 480000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Prepainted Galvanized Steel Coil is made by cold rolled steel sheet and galvanized steel sheets as baseplate,through the surface pretreatment (degreasing,cleaning,chemical conversion processing),coated by the method of continuous coatings (roller coating method), and after roasting and cooling.

Prepainted Galvanized Steel Coil is light,beautiful and has good corrosion resistant performance, can be directly processed also, Prepainted Galvanized Steel Coil provides the construction,shipbuilding,vehicle manufacturing,furniture industry,and electrical industry a new material,while Prepainted Galvanized Steel Coil has good effects on the areas of replacing wood with steel,efficient construction,energy saving,prevent pollution,etc.

Product Details

| Standard: | AISI,ASTM,GB,JIS | Grade: | CGCC/SPCC | Thickness: | 0.14mm-0.8mm |

| Place of Origin: | Shandong China (Mainland) | Brand Name: | Huafeng | Model Number: | 0.14-0.8mm(600-1250mm) |

| Type: | Steel Plate | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Container Plate | Special Use: | High-strength Steel Plate | Width: | 600mm-1250mm |

| Length: | available length | color: | Ral color number | zinc coating: | Z40-180g/m2 |

| coil ID: | 508/610mm | coil weight: | 4-8metric tons | back: | 5-7um |

| top: | 15-17um |

Packaging & Delivery

Packaging Detail:Export standard package :bundled wooden box or be required; The inner size of container is below: 20 ft GP:5.8m(length)x 2.13m(width)x 2.18m(high) about 24-26 CBM 40 ft GP:11.8m(length)x 2.13m(width)x 2.72m(high)about 68 CBM We will packing as the factory ,and reach the stander of export . Or as the customer request.In addition,We will make the products with good surface protection

Delivery Detail:According to the quantity or as per customer's request .

Product Picture

Our Company Introduction

1.Corporate Mission:

Devote to introducing quality products to the world, benefiting people's life. We make every effort to build a first class corporate in Chinese steel import and export line.

2.Corporate Philosophy:

Integrity, Teamwork, Professionalism and Innovation

3.Corporate Values:

Go forward together with the era, Create values together with customers, Develop together with employees

4.Other Products We Do :

Hot rolled coil

Cold rolled coil

Galvanized \ galvalume coil

PPGI/PPGL

Corrugated sheet (roof sheet, wall sheet, decking sheet )

Steel pipes( galvanized, seamless, welded pipe )

Profiled bars(H beam/ I beam/ Angle/ Channel/)

Steel bars and mesh

Please contact me if you are interested in our products and I will try my best to offer you the best goods and service.

- Q: How are steel coils used in the production of metal fencing?

- Steel coils are used in the production of metal fencing by being unrolled, cut, and shaped into various fencing components such as posts, rails, and pickets. These coils provide a consistent and high-quality source of steel, ensuring durability and strength in the final fencing product.

- Q: How are steel coils used in the production of industrial boilers?

- Steel coils are used in the production of industrial boilers to form the main body and components of the boiler, providing strength and durability. The coils are first shaped into the desired boiler structure, such as the shell and tubes, and then welded together to create a sturdy and leak-proof vessel. Additionally, the coils are often used to manufacture the heat exchangers and other critical parts of the boiler, ensuring efficient heat transfer and reliable operation.

- Q: Hi! does anyone know where can i find a building with a structure of steel frames, i need to do an analysis for school so i need joint details, girder details and such! PLEASE help me! thanks

- if u need to analyse a steel framed structure for joint details the best example would be of a mechanic workshop...the truss of such a workshop is always supported on a portal frame and in most of the case thats a steel structure...do keenly observe the joints at the footing plates that is connected to the girder section...nd also observe the joints in truss of such a frame....myslf m a civil engg. student.

- Q: I have a set of Stainless steel pots and pans. Everything is sticks to them. What must I do so things don't stick?

- I only cook acidic foods in stainless steel or tomato sauces, Marinara sauces. Or sauces with wine in it. Because stainless steel is good with those kind of foods. Maybe you should use a little more fat, butter or Olive oil. And don't get the pan too hot, ( I don't care what other ppl say). Sometimes I heat up the pan and put a pat of butter in the pan to judge how hot it is. Once the butter starts sizzling or sputtering, the pan has reached the right temperature. Don't let the butter burn, the pan is too hot if the butter scorches. You can put a tablespoon (or less) olive oil in the skillet first and then a pat of butter; let them blend together. The oil will help keep the butter from burning.

- Q: How are steel coils used in the production of storage racks and shelving?

- Storage racks and shelving heavily rely on steel coils during their manufacturing process. These coils, typically made from high-quality steel, are rolled into long, continuous strips. The steel coils undergo further processing to transform them into sheets or strips, which are then used to construct the frames, shelves, and other structural components of storage racks and shelving systems. Initially, the steel coils go through a series of machines to unwind and flatten them, ensuring uniform thickness and width. This step enables manufacturers to obtain steel sheets or strips with consistent dimensions, which are vital for producing storage racks and shelving that meet specific design specifications and structural requirements. After flattening and cutting the steel coils into desired sizes, they undergo additional processing to incorporate necessary features and characteristics. This may involve bending, punching, or welding the steel to create desired shapes, such as uprights, beams, or brackets for the storage racks and shelving. These components are then assembled to form the framework of the storage system. The durability and strength of steel make it an ideal material for storage racks and shelving. Steel coils provide the essential structural integrity and load-bearing capacity needed to support heavy items and endure regular use. Additionally, steel is resistant to corrosion, ensuring the longevity and reliability of storage racks and shelving systems. Furthermore, steel coils can be coated or galvanized to enhance their resistance to rust and corrosion. This protective layer helps maintain the visual appeal and structural integrity of the storage racks and shelving, particularly in environments with high humidity or exposure to moisture. In conclusion, steel coils play a crucial role in the production of storage racks and shelving. They serve as the raw material for fabricating various components, guaranteeing the strength, durability, and load-bearing capacity necessary for these storage systems. The versatility and adaptability of steel allow manufacturers to create storage racks and shelving that meet specific design requirements and provide long-lasting storage solutions for a wide range of applications.

- Q: Some stainless steel products are as shiny as chrome. Can all/most stainless steel be polished to a chrome like luster.

- No they can not, it depends on the type of finish the stainless steel has. They do make a product called never dull. It is a polishing cloth that will soften the metal as it polishes.

- Q: I'm going to see Man Of Steel this weekend, and the reviews that I've been hearing aren't that good. I've been hearing that it's this depressing, dark, dramatic film with no humor, loud noises, and action on top of action (which is kind of what I expected from this movie). With that said, I was quite positive that this was what the fans wanted, a more serious Super Man interpretation. I'm ultimately going to judge the movie when I see it, but for now, I have 3 short questions for you:1) What did you think of Man Of Steel?2) Superman Returns got somewhat better reviews than Man Of Steel. Does it seem logical?3) There is a huge fan battle between Man Of Steel and Christopher Reeve's version of Super Man. Which one do you favor?

- I loved the new interpretation in Man of Steel Superman Returns got very poor reviews in the beginning, and as the hatred has worn off and fans have been the only ones voting, the score has moved up. As fond as I am of Christopher Reeves, his version was a touch campy. I much prefer the serious treatment.

- Q: How are steel coils used in the production of steel screws?

- Steel coils are used in the production of steel screws as they serve as the raw material for manufacturing the screws. The steel coils are unwound and fed into a machine that cuts and shapes the steel into the desired screw form. This process ensures that the screws are made from high-quality steel and have the necessary strength and durability.

- Q: How are steel coils used in the manufacturing of power generation equipment?

- Steel coils are used in the manufacturing of power generation equipment as they serve as a primary material for constructing various components such as turbines, generators, and transformers. The steel coils are shaped, cut, and welded to create sturdy structures that can withstand high temperatures and pressures, ensuring reliable and efficient power generation.

- Q: With the Reduced weight of steel,wouldn't the projectile be at a much higher velocity when fired causing more damage?I mean l couldn't steel be worked to seal the bore,not damage the rifling and still cheap enough to mass produce,and be light enough to carry much more ammo.

- The bullet needs to be a bit malleable to conform to the grooves in the barrel. In an American .30 gun a .308 bullet is forced out of the gun it has to conform to the .30 bore and .308 grooves to form a tight seal. That's why lead and copper are the primary materials of the bullet. A steel bullet in a steel bore would potentially produce a pipe bomb or at least do significant damage to the bore. Also, the weight of bullets are optimized for their application with the current materials. There is no need or desire to reduce the mass of the bullet. Simply reducing mass for increased velocity can effect the terminal ballistics in all kinds of ways, but you cannot assume that damage will be higher for a variety of reasons. If nothing else the fact that the military has INCREASED the 5.56x45mm from 55gr to 62gr should be enough to doubt your claim. Also steel is about 70% the density of lead, so there would not be a major savings in mass, but aluminum is only 25% the density and it is much closer to the hardness of lead. If you really wanted a light bullet, the aluminum may be the way to go.

Send your message to us

Best sell Prepainted Galvanized Steel Coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4800 PCS

- Supply Capability:

- 480000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords