Ball Mill Liner Plate With Alloy Steel Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Mill Liner Plate With Alloy Steel Materials

Alloy steel is steel that is alloyed with a variety of elements to improve its mechanical properties.In wear resistant industry,Chromium,Mo,Nickle are added into carbon steel to achieve wear resistance and corrosion resistance properties.

In our company ,we divide alloy steel into 6 groups according to the element be added:

Low chromium Alloy Steel(Cr2)

Medium Chromium Alloy Steel(Cr5)

Cr-Mo Alloy Steel (Cr5Mo)

Cr-Mo Ni Alloy Steel(Cr5MoNi)

Low carbon high chromium Alloy Steel(Cr8Cu)

Low carbon Mo-Cr-Ni Alloy Steel

| Name | C | Mn | Cr | Si | S,P | Cu | Mo | Ni |

Cr2 | 0.3-1.2 | 0.3-1.5 | 1.0-3.0 | 0.3-1.5 | ≤0.06 | |||

Cr5 | 0.3-0.65 | 0.3-1.2 | 4.0-6.0 | 0.3-1.2 | ≤0.06 | |||

Cr5Mo | 0.3-0.65 | 0.3-1.2 | 4.0-6.0 | 0.3-1.2 | ≤0.06 | 0.3-1.0 | 0.3-1.0 | |

Cr5MoNi | 0.3-0.65 | 0.3-1.2 | 4.0-6.0 | 0.3-1.2 | ≤0.06 | |||

Cr8Cu | 0.2-0.35 | 0.3-1.2 | 6.0-9.0 | 0.3-1.2 | ≤0.06 | 0.3-1.0 | ||

Cr8MoNiCu | 0.2-0.35 | 0.3-1.2 | 6.0-9.0 | 0.3-1.2 | ≤0.06 | 0.3-1.0 | 0.3-1.0 | 0.3-1.0 |

The mechanical property after heat treating:44-54HRC;10-60J/cm2

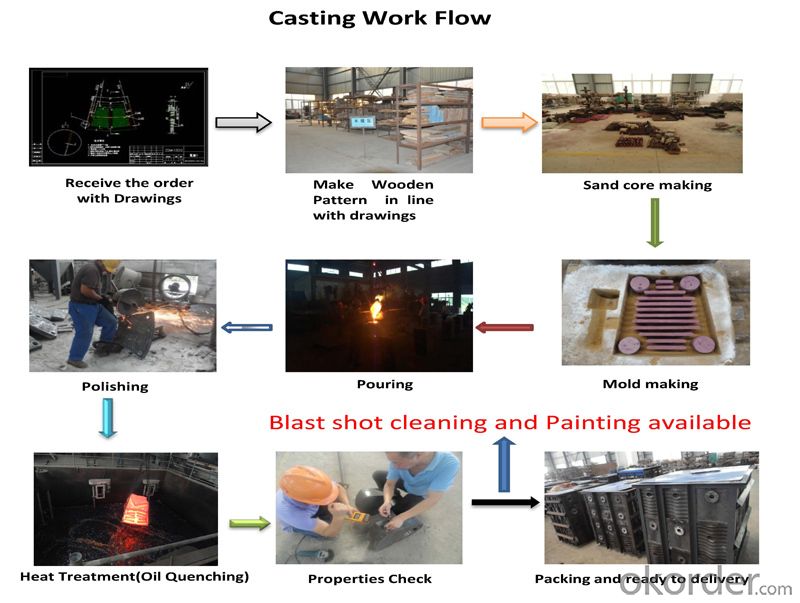

Heat Treatment Method

1.Oil Quenching

Fog Quenching

Tempering:

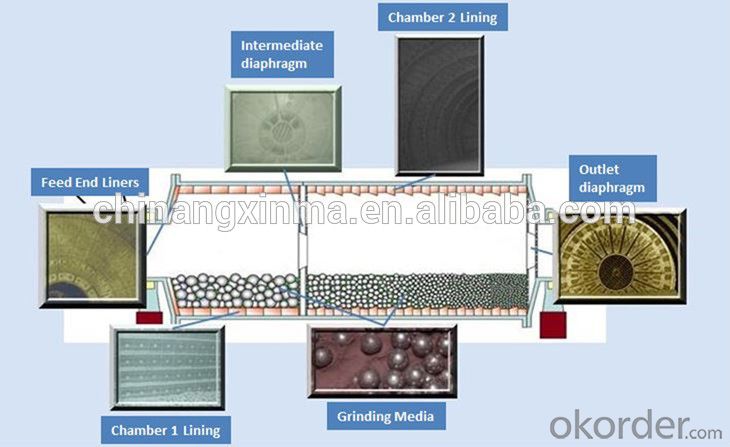

The other products we offer for ball mill as the following picture

Company Information

- Q: How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q: Why do cheap cars like stamping parts instead of casting parts?

- The difference between automobile stamping parts and castingsAs the saying goes, there will be progress in comparison. In fact, through comparison, we can find the advantages and disadvantages of both. Next, we will talk about the difference between car stamping parts and castings.Looking for national casting orders, ductile iron castings, purchasing castings, foundry orders, and consulting foundry technology issuesCasting order networkAutomotive stamping parts are widely used in every field of our life, including some electronic components, auto parts, decorative materials and so on.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- The molten iron (molten iron, scrap steel, scrap casting, iron alloy) is melted into cast iron by means of an electric furnace or cupola, and is poured into a casting.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: How can the casting be quenched and tempered?

- Cast steel annealing or normalizing parts in strength and toughness is insufficient, can be used in quenching and tempering treatment. It is mainly used for gear, gear and other parts of the cast steel. The conditioning has two kinds: one kind is cast directly after quenching and tempering, with warm water (40---50 degrees) intermittent cooling, suitable for ZG270---500, ZG310----570 and other castings.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- There are various casting stresses after casting, which can be divided into two kinds: thermal stress and shrinkage stress. In a long time placed in the atmosphere, called aging treatment.Aging treatment is an effective measure to eliminate casting stress. Aging is divided into natural aging, thermal aging and resonance aging.1, the so-called natural aging, the casting is placed in the open field for more than half a year, so that the internal stress relief.

- Q: What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- For example Changchun FAW, under a casting, two casting and other casting plant, but there are more than half of all outsourcing in Tianjin Hebei Shandong purchase, many automobile enterprises to casting foundry.

- Q: How to solve casting defect casting?

- Prevention methodReduce the gas in the metal liquid and oxidize the slag, improve the fluidity of the metal liquidIncrease pouring temperature and pouring speed, strengthen slag collection, slag block or bottom pouring bag, teapot ladle pouring, can not cut off when pouring, prevent the slag from blocking the nozzle, and cause the casting to breakIncrease the sprue and sprue height, increase the runner section area and the sprue number, and improve the filling speed and the metal hydrostatic headImprove the casting design and increase the thickness of the thin-wall part of the castingChange the pouring position and pouring system, the casting thin wall plane is located at the top and away from the gate, to prevent the filling of liquid metal splashing, eddy current, avoid metal stream in the casting thin sections or core support, cold iron, insert the confluence, when necessary, take horizontal vertical pouring cold or inclined castingIncrease the permeability of core and sand, strengthen the exhaust of mould, and the quantity of air outlet and riser should be enoughChange the size and location of the core, the inner cold iron, the core support, the internal cold iron, the insert should be no rust, no oil pollutionCheck the type, tight box, press the operation of iron is safe, to prevent running fire

- Q: The difference between sheet metal and casting parts

- Sheet metal refers to the metal sheet (which can be bent straight board, etc.) generally uniform thickness, can obtain the required parts by stamping, molding, welding, splicing and other processing methods.

Send your message to us

Ball Mill Liner Plate With Alloy Steel Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords