ASTM A615/BS4449 Reforcing Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 180 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

ASTM A615/BS4449 Reforcing Steel Bar

Description of ASTM A615/BS4449 Reforcing Steel Bar

1, Diameter: 5.5mm-10mm ASTM A615/BS4449 Reforcing Steel Bar

10m- 40mm ASTM A615/BS4449 Reforcing Steel Bar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of ASTM A615/BS4449 Reforcing Steel Bar

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

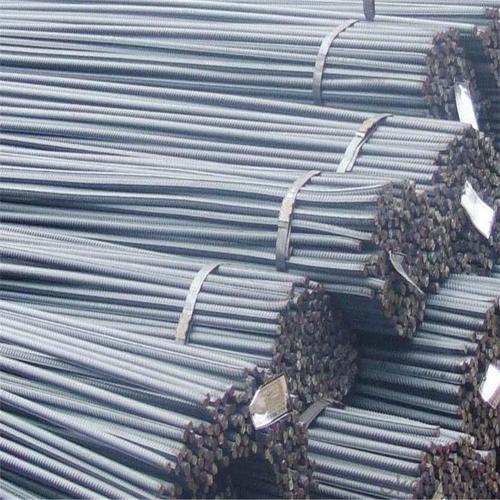

Products Show of ASTM A615/BS4449 Reforcing Steel Bar

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different powder coating techniques used for special steel?

- There are several powder coating techniques used for special steel, including electrostatic spraying, fluidized bed coating, and electrostatic fluidized bed coating. These techniques involve applying a dry powder coating to the steel surface, which is then cured to form a durable and protective layer. Each technique has its own advantages and is used based on the specific requirements of the steel and the desired finish.

- Q: What are the requirements for special steel used in low-temperature applications?

- Special steel used in low-temperature applications must meet certain requirements to ensure its performance and reliability in such conditions. These requirements primarily revolve around three key factors: toughness, resistance to brittle fracture, and corrosion resistance. Toughness is of utmost importance in low-temperature applications because it determines a material's ability to absorb energy and resist cracking or fracturing. Special steel for low-temperature applications should have high toughness, which is typically achieved through the addition of certain alloying elements such as nickel and manganese. These elements enhance the steel's ability to withstand impact loads and prevent catastrophic failures. Resistance to brittle fracture is another crucial requirement for steel used in low-temperature environments. At low temperatures, steel becomes more susceptible to brittle fracture, which can occur without any significant deformation or warning. To mitigate this risk, special steel for low-temperature applications undergoes specific heat treatment processes to refine its microstructure and improve its resistance to brittle fracture. Corrosion resistance is also an essential requirement for special steel used in low-temperature applications. Low temperatures can often lead to the formation of ice or condensation, which can introduce moisture and potentially corrosive substances to the steel's surface. Therefore, the steel must have excellent corrosion resistance properties to prevent degradation and maintain its structural integrity over time. This is commonly achieved through the addition of corrosion-resistant elements such as chromium and molybdenum. In addition to these primary requirements, other factors such as dimensional stability, weldability, and cost-effectiveness should also be considered when selecting special steel for low-temperature applications. The material should have good dimensional stability to ensure it retains its shape and mechanical properties under varying temperature conditions. It should also be easily weldable to facilitate construction and maintenance processes. Moreover, the selected steel should be cost-effective, balancing its performance with the overall project budget. Overall, special steel used in low-temperature applications must possess high toughness, resistance to brittle fracture, and corrosion resistance. Meeting these requirements ensures the steel's reliability and longevity in challenging low-temperature environments, allowing for safe and efficient operation in various industries such as cryogenic storage, oil and gas exploration, and transportation.

- Q: What are the challenges in manufacturing special steel?

- Some of the challenges in manufacturing special steel include the high cost of raw materials, the complex and precise production processes, ensuring consistent quality and performance, meeting specific customer requirements, and staying up-to-date with rapidly advancing technologies and industry standards. Additionally, the demand for customization and shorter lead times can also present challenges in terms of production planning and logistics.

- Q: How does special steel contribute to reducing weight in applications?

- Special steel contributes to reducing weight in applications through its unique properties and manufacturing processes. Special steel alloys are engineered to have high strength-to-weight ratios, allowing them to provide the same structural integrity as conventional steel but at a reduced weight. These alloys often contain elements like chromium, nickel, and molybdenum, which enhance their strength and durability. Additionally, special steel can be manufactured through advanced techniques such as hot rolling, cold rolling, and heat treatment. These processes further refine the steel's microstructure, improving its mechanical properties while maintaining a lightweight composition. By using special steel in various applications, such as automotive parts, aerospace components, and construction materials, manufacturers can achieve weight reduction without compromising performance or safety.

- Q: What are the common applications of special steel in the manufacturing industry?

- Special steel, also known as alloy steel, is widely used in the manufacturing industry due to its unique properties and superior performance in various applications. Some common applications of special steel in the manufacturing industry include: 1. Automotive Industry: Special steel is extensively used in the manufacturing of automobile components such as engine parts, gears, axles, and crankshafts. The high strength, durability, and resistance to wear and corrosion make special steel an ideal choice for these critical automotive applications. 2. Aerospace Industry: Special steel plays a vital role in the aerospace sector, where it is used for manufacturing aircraft components like landing gear, turbine blades, and structural parts. The high tensile strength, lightweight nature, and ability to withstand extreme temperatures make special steel indispensable for ensuring the safety and efficiency of aircraft operations. 3. Construction Industry: Special steel finds widespread use in the construction sector for manufacturing structural elements like beams, columns, and reinforcement bars. The superior strength, ductility, and resistance to external forces make special steel an essential material for ensuring the structural integrity and safety of buildings, bridges, and other infrastructure projects. 4. Oil and Gas Industry: Special steel is extensively utilized in the oil and gas industry for manufacturing pipelines, drill bits, valves, and other equipment. The high resistance to corrosion, pressure, and extreme temperatures make special steel suitable for handling the harsh operating conditions encountered in oil and gas exploration, extraction, and transportation. 5. Tool and Die Making: Special steel is commonly employed in tool and die making due to its excellent hardness, toughness, and wear resistance. It is used for manufacturing cutting tools, molds, dies, and punches required in various industries such as automotive, aerospace, and consumer goods manufacturing. 6. Medical Industry: Special steel finds applications in the manufacturing of surgical instruments, implants, and medical devices. The biocompatibility, corrosion resistance, and sterilizability of special steel make it an ideal material for ensuring the safety and effectiveness of medical tools and implants. These are just a few examples of the common applications of special steel in the manufacturing industry. The versatility, reliability, and performance of special steel make it a preferred material choice in numerous other sectors, contributing to the advancement and growth of various manufacturing processes.

- Q: How does special steel contribute to the renewable energy conversion efficiency?

- Special steel plays a crucial role in enhancing the renewable energy conversion efficiency by providing durability, strength, and resistance to extreme conditions. It is used in the construction of wind turbines, solar panels, and hydropower systems, ensuring their reliability and longevity. Moreover, special steel alloys facilitate the development of more efficient and lightweight components, reducing energy losses and optimizing the overall performance of renewable energy systems.

- Q: How does special steel perform in terms of electrical conductivity?

- Special steel generally has poor electrical conductivity compared to other metals such as copper or aluminum. However, its electrical conductivity can be improved through specific alloying elements and heat treatments.

- Q: How is die steel used in metal stamping processes?

- Die steel is commonly used in metal stamping processes due to its high strength, hardness, and wear resistance properties. It is used to create dies, which are specialized tools that shape and cut metal sheets or strips into desired shapes. Die steel ensures that the dies can withstand the high forces and repetitive actions involved in metal stamping, allowing for precise and efficient production of various metal components and products.

- Q: What are the main applications of special steel in the mining transportation?

- Special steel is widely used in mining transportation for various applications. One of the main applications is in the manufacturing of mining equipment such as drill bits, cutting tools, and conveyor belts. Special steel's superior strength, hardness, and resistance to wear and corrosion make it ideal for these components, ensuring their durability and longevity in harsh mining environments. Additionally, special steel is also used in the construction of mine shafts, tunnels, and bridges, where its high tensile strength and resistance to extreme temperatures are crucial. Overall, special steel plays a vital role in enhancing the performance, safety, and efficiency of mining transportation systems.

- Q: How does special steel contribute to improved product performance?

- There are multiple ways in which special steel contributes to enhancing product performance. Firstly, special steel is renowned for its outstanding strength and durability. This means that products made from special steel can withstand heavy loads, high temperatures, and harsh environments without distorting or fracturing. As a result, the extended strength and durability of special steel lead to a longer lifespan for the product and reduced maintenance needs. Moreover, special steel possesses remarkable resistance to corrosion. It is less prone to rust and other types of corrosion, making it the perfect choice for products that are exposed to moisture or chemicals. This corrosion resistance ensures that the product remains in optimal condition, even in corrosive surroundings, and minimizes the need for frequent replacements. Additionally, special steel offers superior heat resistance. It can endure extreme temperatures without compromising its mechanical properties, such as strength and hardness. This attribute makes it suitable for products that operate in high-temperature conditions, including engines, turbines, and exhaust systems. The ability of special steel to retain its properties at elevated temperatures significantly enhances product performance and reliability. Furthermore, special steel can be customized to meet specific requirements through the utilization of different alloying elements and heat treatment processes. This customization enables manufacturers to finely adjust the material properties to suit the intended application, thereby resulting in improved product performance. For instance, by modifying the alloying elements, special steel can exhibit enhanced wear resistance, impact resistance, or hardness, depending on the desired application. To summarize, special steel contributes to improved product performance by offering exceptional strength, durability, corrosion resistance, heat resistance, and customization options. These properties not only extend the lifespan of the product but also enhance its reliability and performance in challenging conditions, ultimately benefiting the end-users.

Send your message to us

ASTM A615/BS4449 Reforcing Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 180 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords