BS4449 ASTM A615 DCL Reinforcing Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,ASTM,JIS,GB,DIN,API,EN,BS

Technique:

Cold Rolled,Hot Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

6-34mm

Width:

6-34mm

Length:

12m

Outer Diameter:

6-34mm

Net Weight:

10kg

Packaging:

seaworthy packaging

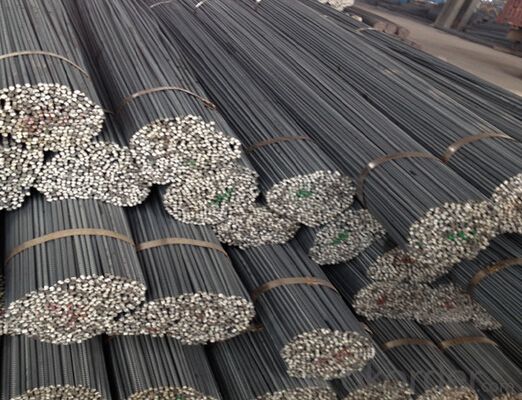

BS4449 ASTM A615 DCL Reinforcing Steel Rebar

Details of the BS4449 ASTM A615 DCL Reinforcing Steel Rebar

| Standard & Grade: | GB1499-98 : HRB335,HRB400,HRB500 |

| BS4449-1997 : GR460,GR500 | |

| CAN/CSA-G30.18-M92 : 400W | |

| ASTM A615 : Gr.40, Gr.60 | |

| Diameter: | 6mm;8mm;10mm;12mm;14mm;16mm;18mm;20mm;22mm;25mm;28mm;30mm;32mm;35mm;40mm |

| Length: | 6m,9m,12m |

| Packing: | Bundle packing |

| Origin: | China |

| Application: | Construction,Road,Machinery processing,Welding fields. |

| Delivery time: | 10-25 days |

| Shipment: | By bulk vessel or Container |

| Documents: | Mill Test Certificate,Commercial Invoice,Packing List,Certificate of Origin |

Company Introduction of the BS4449 ASTM A615 DCL Reinforcing Steel Rebar

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of the BS4449 ASTM A615 DCL Reinforcing Steel Rebar

| Packaging Detail | Sea worthy packing /as per customer's packing instruction |

| Delivery Detail | 15 ~ 40 days after receiving the deposit |

FAQ

| Are you a trading company or manufacturer? | Manufacturer |

| What’s the MOQ? | 1000m2 |

| What’s your delivery time? | 15-20 days after downpayment received |

| Do you Accept OEM service? | Yes |

| what’s your delivery terms? | FOB/CFR/CIF |

| What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

| Western Union acceptable for small amount. | |

| L/C acceptable for large amount. | |

| Scrow ,Paybal,Alipay are also ok | |

| Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

| What's your available port of Shipment? | Main Port, China |

| What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

| Where are your Market? | Covering more than 160 countries in the world |

- Q: What is the difference between black and epoxy-coated steel rebars?

- The main difference between black and epoxy-coated steel rebars is the presence of a protective coating on the latter. Black steel rebars are bare steel bars that are susceptible to corrosion, while epoxy-coated steel rebars have a layer of epoxy coating that acts as a barrier against corrosion. This coating provides enhanced durability and longevity to the rebar, making it more suitable for use in environments where corrosion is a concern, such as in coastal areas or concrete structures exposed to chemicals.

- Q: How are steel rebars classified based on their surface patterns?

- There are two main categories for classifying steel rebars, which are based on their surface patterns. These categories include plain rebars and deformed rebars. Plain rebars have a smooth and plain surface without any surface patterns or deformations. They are mainly used in situations where the concrete needs to slide along the rebar, such as in bridges and highway pavements. The smooth surface of plain rebars ensures a strong bond between the steel and concrete, allowing for good load transfer between the two materials. On the other hand, deformed rebars have surface patterns or deformations that improve their bond with concrete. These patterns can take the form of ribs, indentations, or other irregularities. Deformed rebars provide better mechanical anchoring to the concrete, preventing slippage and enhancing the overall structural integrity of reinforced concrete structures. Furthermore, deformed rebars are further classified based on the type and shape of their surface patterns. Some common types include ribbed rebars, indented rebars, and twisted rebars. Ribbed rebars have continuous, evenly spaced ribs along their entire length, ensuring strong bonding strength with the concrete even under heavy loads. Indented rebars have indentations or impressions along their length, increasing the surface area and enhancing the bond between the steel and concrete. Twisted rebars have a twisted pattern along their length, providing additional mechanical interlocking between the rebar and concrete. The choice of rebar surface pattern depends on the specific requirements of the construction project. Factors such as the type of structure, load-bearing capacity, and local building regulations play a crucial role in determining the appropriate classification of steel rebars based on their surface patterns.

- Q: Do l 8, three grade steel have discs?

- Yes, but because of the higher grade of the three screw thread, they are straight bars. It's not necessary to use grade three for 8 mm.

- Q: What are the methods used for corrosion protection of steel rebars?

- There are several methods used for corrosion protection of steel rebars. 1. Coating: One common method is to apply a protective coating on the surface of the steel rebar. This coating acts as a barrier, preventing moisture and oxygen from reaching the steel surface and causing corrosion. Coatings can be applied using various techniques such as hot-dip galvanizing, epoxy coatings, or fusion-bonded epoxy coatings. 2. Cathodic Protection: Another method is cathodic protection, which involves the use of sacrificial anodes or impressed current systems. Sacrificial anodes are made of a more reactive metal (such as zinc or magnesium) that corrodes over time instead of the steel rebar. This ensures that the steel remains protected. Impressed current systems use an external power source to provide a protective current to the steel rebar, preventing corrosion. 3. Concrete cover: A simple but effective method is to provide a sufficient concrete cover over the steel rebar. The concrete acts as a physical barrier, shielding the steel from the environment. The thickness of the concrete cover is critical and should be designed according to specific standards to ensure adequate protection. 4. Inhibitors: Corrosion inhibitors can be added to the concrete mix or applied on the surface of the steel rebar. These inhibitors work by reducing the corrosive effects of moisture and oxygen on the steel surface. They can be organic or inorganic compounds that form a protective layer on the steel, inhibiting the corrosion process. 5. Proper design and construction practices: Lastly, proper design and construction practices can greatly contribute to corrosion protection. This includes avoiding the use of dissimilar metals that can cause galvanic corrosion, ensuring proper drainage to prevent water accumulation, and taking measures to minimize exposure to corrosive environments. It is important to note that a combination of these methods is often used to provide optimal corrosion protection for steel rebars, depending on the specific project requirements and environmental conditions.

- Q: What are the main uses of steel rebars?

- Steel rebars, otherwise known as reinforcing bars, serve as a crucial component in construction and civil engineering endeavors, granting robustness and steadiness to concrete structures. The primary applications of steel rebars encompass the following: 1. Reinforcement of Concrete: Steel rebars are strategically integrated within concrete structures to heighten their tensile strength. While concrete exhibits commendable resistance against compressive forces, it remains vulnerable in terms of tension. By incorporating rebars, the resulting composite material (reinforced concrete) is endowed with the ability to withstand both compressive and tensile forces, rendering it suitable for various applications such as building columns, beams, slabs, and foundations. 2. Enhancement of Structural Stability: Steel rebars play a pivotal role in elevating the structural stability of edifices and infrastructures. They facilitate the uniform distribution of loads across the structure, preventing the occurrence of cracks, sagging, or collapse. Through the reinforcement of concrete elements with rebars, structures become capable of enduring substantial loads, seismic activity, and other external forces. 3. Bridges and Highways: Steel rebars find extensive employment in the construction of bridges and highways. As bridges are routinely subjected to substantial loads and harsh environmental conditions, robust and durable reinforcement is imperative. Steel rebars ensure the longevity and structural integrity of these critical infrastructure projects. 4. Retaining Walls and Tunnels: Retaining walls serve the purpose of holding back soil or other substances, thereby preventing erosion. Steel rebars are commonly employed to reinforce these structures, enabling them to withstand the lateral pressures exerted by the retained material. Similarly, in tunnel construction, rebars bestow strength upon the concrete lining, ensuring stability and averting collapse. 5. Foundations: Steel rebars form an indispensable constituent in the construction of building foundations. They contribute to the even distribution of the structure's weight onto the ground, thereby averting the occurrence of settlement or sinking. Furthermore, rebars anchor the foundation to the ground, endowing it with stability against soil movement or seismic forces. 6. Pre-stressed and Post-tensioned Concrete: In the realm of pre-stressed and post-tensioned concrete construction, steel rebars are employed to introduce compressive forces into the concrete members. This technique elevates the structural performance by diminishing tensile stress, augmenting load-bearing capacity, and minimizing cracking. 7. Masonry Reinforcement: Steel rebars are also utilized to reinforce masonry structures such as walls, columns, and arches. By embedding rebars within mortar joints or cores, the overall strength and stability of the masonry system are enhanced, enabling it to withstand lateral loads and seismic forces. To summarize, steel rebars are indispensable in contemporary construction endeavors, furnishing concrete structures with strength, stability, and durability. By virtue of their capacity to resist tensile forces, they ensure the well-being and longevity of buildings, bridges, highways, tunnels, and other crucial infrastructure projects.

- Q: Are there any environmental benefits to using steel rebars?

- Yes, there are several environmental benefits to using steel rebars in construction. Here are some of the key advantages: 1. Recyclability: Steel rebars are highly recyclable, meaning they can be reused or repurposed after their lifespan in a structure ends. This reduces the demand for new steel production and the associated energy consumption and greenhouse gas emissions. In fact, steel is one of the most recycled materials globally, with a recycling rate of around 90%. 2. Durability: Steel rebars are known for their strength and durability, which allows structures to last longer. This reduces the need for frequent replacements or repairs, resulting in less waste generation and the conservation of resources. 3. Energy efficiency: Steel production has become increasingly energy-efficient over the years, with advancements in technology and processes. This means that the environmental impact of steel production has been decreasing, making it a more sustainable choice compared to other materials. 4. Reduced deforestation: Steel rebars offer an alternative to timber reinforcement, which is often sourced from deforestation practices. By using steel rebars instead, we can help reduce the pressure on forests and protect their valuable ecosystem services. 5. Reduced waste: Steel rebars can be prefabricated and cut to specific lengths, minimizing waste on construction sites. Additionally, the scrap generated during the fabrication process can be recycled, further reducing waste generation. Overall, using steel rebars in construction offers various environmental benefits, including recyclability, durability, energy efficiency, reduced deforestation, and waste reduction. These advantages contribute to a more sustainable and environmentally-friendly construction industry.

- Q: How do steel rebars prevent corrosion in concrete structures?

- Steel rebars prevent corrosion in concrete structures through the process of passivation. Passivation is the formation of a thin, protective oxide layer on the surface of the steel rebar, which acts as a barrier against corrosion-causing agents. When steel rebars are embedded in concrete, the alkaline environment created by the cement paste helps in passivating the steel. The high pH level of the concrete creates a protective layer of iron oxide (rust) on the rebar's surface, preventing the steel from coming into contact with moisture and oxygen. Furthermore, the dense and impermeable nature of well-constructed concrete limits the movement of water and other corrosive substances towards the steel rebars. This reduces the likelihood of corrosion initiation and its progression. In addition to the alkaline environment and concrete's impermeability, steel rebars are also typically coated with a layer of epoxy or zinc to provide an extra layer of protection. These coatings further enhance the resistance of the steel to corrosion, particularly in aggressive environments such as marine or chloride-rich conditions. Regular maintenance and preventive measures, such as ensuring proper concrete cover over the rebars and avoiding the presence of excessive moisture or chloride ions, also play a crucial role in preventing corrosion in concrete structures.

- Q: What are the guidelines for proper tying of steel rebars in concrete structures?

- To ensure the structural integrity and durability of concrete structures, it is crucial to adhere to guidelines for the proper tying of steel rebars. Here are some important guidelines to consider: 1. Rebar Placement: Before tying, accurately position the rebars according to the structural drawings and design specifications. Place them at the designated locations and depths, ensuring proper spacing to provide the necessary strength and reinforcement. 2. Tying Tools: Utilize suitable tools like pliers or rebar tying machines for secure and proper tying. Ensure that the tools are in good condition and appropriate for the size and type of rebars being used. 3. Tying Technique: Employ a consistent and efficient tying technique. Begin by securely holding the rebars together at the intersection point. Wrap the tie wire around both rebars multiple times, ensuring tight and firm connections. Properly twist and neatly cut the tie wire to avoid any protrusions. 4. Tie Wire Selection: Use high-quality tie wires with sufficient strength to withstand tension and load requirements. Opt for corrosion-resistant materials such as galvanized steel or stainless steel to prevent rusting and deterioration over time. 5. Tying Spacing: Adhere to the specified tying spacing as per the design requirements. Adequate spacing between ties helps maintain rebars in their designated positions, preventing displacement during concrete pouring and subsequent curing. 6. Tying Quantity: Tie rebars at suitable intervals to ensure ample connection and reinforcement. The number of ties needed depends on the size, shape, length of rebars, and structural design specifications. 7. Tying Consistency: Maintain consistency in tying throughout the entire concrete structure. Uneven or inconsistent tying can result in weak points, reduced reinforcement, and compromised structural integrity. 8. Tying Safety: Prioritize safety during the tying process. Wear appropriate personal protective equipment (PPE) like gloves and safety glasses to prevent injuries. Take precautions to avoid tripping hazards and ensure a safe working environment. 9. Inspection and Quality Control: Regularly inspect the tied rebars to ensure compliance with design specifications and quality standards. Conduct visual inspections and perform pull tests to assess the strength and effectiveness of the ties. 10. Compliance with Codes and Standards: Adhere to local building codes, industry standards, and engineering guidelines specific to your region. These codes provide essential requirements for rebar tying, ensuring the durability and safety of the concrete structure. By following these guidelines, construction professionals can enhance the strength, stability, and longevity of concrete structures through proper tying of steel rebars.

- Q: How do steel rebars affect the overall noise insulation of a structure?

- The overall noise insulation of a structure is minimally affected by steel rebars. This is because noise insulation primarily relies on the density and thickness of the construction materials used for walls, floors, and ceilings. Steel rebars, which are used to reinforce concrete structures, do not make a significant contribution to a building's sound insulation properties. The main purpose of steel rebars is to provide strength and stability to the concrete, ensuring its structural integrity. They are typically embedded within the concrete, thus present throughout the building's framework. However, steel rebars themselves do not possess any sound-absorbing or sound-blocking characteristics. To enhance the noise insulation of a structure, other materials specifically designed for sound insulation, such as insulation boards, acoustic panels, or soundproofing materials, need to be incorporated into the building design. These materials are intended to absorb or block sound waves, reducing the transmission of noise from one area to another. Although steel rebars do not directly contribute to noise insulation, they indirectly play a role in maintaining the overall structural integrity of a building. A well-constructed and sturdy structure can help minimize vibrations and sound transmission caused by external noise sources. Therefore, while steel rebars themselves do not significantly affect noise insulation, their presence indirectly contributes to a more solid and stable building, which can help reduce structural vibrations and unwanted noise.

- Q: How are steel rebars protected from theft during construction?

- Steel rebars are protected from theft during construction through various measures such as storing them in secure areas, implementing strict access control, utilizing surveillance systems, and employing security personnel. Additionally, some construction sites may also use special marking or tracking systems on the rebars to deter theft and aid in their recovery if stolen.

Send your message to us

BS4449 ASTM A615 DCL Reinforcing Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords