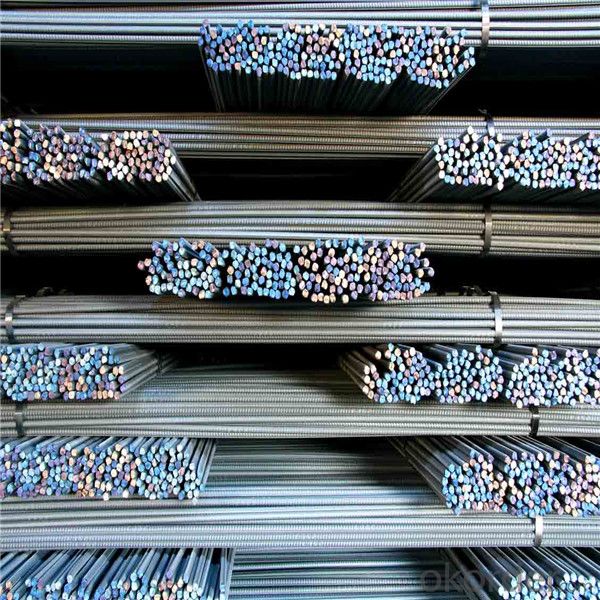

Reinforcing Steel Rebar BS4449 ASTM A615 DCL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 19000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Rebar is common steel reinforcing bar, an important component of reinforced concrete and reinforced masonry structures.

It is usually formed from mild steel, and is given ridges for better frictional adhesion to the concrete.

Concrete is a material that is very strong in compression, but virtually without strength in tension. To compensate for this

imbalance in concrete's behavior, rebar is formed into it to carry the tensile loads.

Most grades of steel used in rebar cannot accept welding; such as, to adjacent steel plates or as means to bind single pieces of rebar together. However, special grades of rebar steel and welding rods make welding by expert welders possible.

To prevent workers from accidentally impaling themselves, the protruding ends of steel rebar are often bent over or covered with special plastic "mushroom" caps.

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q:Can steel rebars be used in structures with high levels of carbonation or acid attack?

- No, steel rebars should not be used in structures with high levels of carbonation or acid attack. Steel is susceptible to corrosion in acidic environments, and high carbonation levels can increase the acidity of the surroundings. In such conditions, alternative materials that are resistant to corrosion and acid attack, such as stainless steel or fiber-reinforced polymers, should be considered for structural reinforcement.

- Q:Can steel rebars be used in school construction?

- Yes, steel rebars can be used in school construction. Steel rebars are commonly used in the construction industry as reinforcement for concrete structures, including schools. They provide strength and durability to the building, ensuring its long-term stability and resistance to various forces, such as earthquakes or heavy loads.

- Q:How do steel rebars affect the durability of concrete structures?

- Steel rebars greatly enhance the durability of concrete structures. By reinforcing the concrete, rebars improve its tensile strength, preventing cracking and enhancing its ability to withstand external forces and loads. This reinforcement also helps to increase the overall lifespan of the structure, making it more resistant to corrosion, fatigue, and other forms of degradation.

- Q:Can steel rebars be used in other construction materials apart from concrete?

- Yes, steel rebars can be used in other construction materials apart from concrete. They can also be utilized in masonry structures, timber frames, and even in composite materials. The high strength and durability of steel rebars make them suitable for reinforcing various construction materials, enhancing their structural integrity and load-bearing capacity.

- Q:Can steel rebars be used for both residential and commercial construction?

- Yes, steel rebars can be used for both residential and commercial construction. Steel rebars are commonly used as reinforcement in concrete structures to provide additional strength and stability. They are suitable for various construction projects, including residential buildings, commercial buildings, bridges, and infrastructure projects. The use of steel rebars ensures that the concrete structure can withstand heavy loads, seismic activity, and other external forces. Whether it is a small residential house or a large commercial complex, steel rebars are a reliable and commonly used material for reinforcing concrete structures in both residential and commercial construction.

- Q:Can steel rebars be used in historical monument conservation?

- Yes, steel rebars can be used in historical monument conservation. They are commonly used to reinforce and strengthen structures, including historical monuments, to ensure their stability and longevity. However, it is important to carefully consider the specific requirements and limitations of each monument to ensure that the use of steel rebars does not compromise its historical integrity or aesthetic value.

- Q:What is the role of steel rebars in preventing cracks in concrete?

- Steel rebars play a crucial role in preventing cracks in concrete by providing tensile strength. As concrete is strong in compression but weak in tension, rebars act as reinforcement, absorbing and distributing the tensile forces that would otherwise cause cracks. By resisting the tension, rebars reinforce the concrete structure, enhance its durability, and ensure it remains stable and crack-resistant over time.

- Q:What is the process of joining steel rebars together?

- The process of joining steel rebars together is commonly done through methods such as overlap splicing, mechanical splicing, and welding. In overlap splicing, two rebars are overlapped and tied together using wire or steel straps. Mechanical splicing involves using couplers or threaded connectors to join rebars together. Welding, on the other hand, involves melting the ends of two rebars and fusing them together using heat. Each method has its own advantages and considerations, depending on factors like the structural requirements and project specifications.

- Q:How are steel rebars protected against theft on construction sites?

- Steel rebars are often protected against theft on construction sites through various security measures. These measures can include the use of surveillance cameras, security guards, fencing, and locked storage areas. Additionally, some construction sites may employ the use of tagging or marking systems on the rebars themselves to make them easily traceable and identifiable.

- Q:What is the effect of steel rebars on the formwork design?

- Steel rebars have a significant effect on the formwork design in construction projects. These rebars, also known as reinforcement bars, are used to provide strength and stability to concrete structures. One of the main effects of steel rebars on formwork design is the need for proper positioning and spacing of the rebars within the formwork. The formwork needs to be designed to accommodate the rebars and allow for their proper placement in order to ensure the structural integrity of the concrete element. This may involve creating openings or recesses in the formwork to allow the rebars to pass through. The presence of steel rebars also affects the size and dimensions of the formwork. Since the rebars occupy space within the concrete element, the formwork needs to be adjusted accordingly to accommodate these additional materials. This may require increasing the size or thickness of the formwork to accommodate the desired concrete cover over the rebars. Another effect of steel rebars on formwork design is the consideration of the weight and load-bearing capacity of the formwork system. Steel rebars can add significant weight to the concrete structure, and the formwork needs to be designed to withstand this additional load. This may involve using stronger and more robust materials for the formwork, as well as ensuring proper bracing and support. Furthermore, the presence of steel rebars may also impact the formwork construction process. The formwork needs to be carefully designed to allow for the installation and removal of the rebars without compromising the integrity of the formwork system. This may involve incorporating removable sections or panels in the formwork design to facilitate the placement and removal of the rebars. In conclusion, steel rebars have a significant effect on the formwork design in construction projects. They require careful consideration and planning to ensure proper positioning, spacing, and support within the formwork. The presence of rebars also affects the size, dimensions, weight, and construction process of the formwork system. Overall, proper integration of steel rebars within the formwork design is crucial for the successful construction of durable and structurally sound concrete elements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Reinforcing Steel Rebar BS4449 ASTM A615 DCL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 19000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords