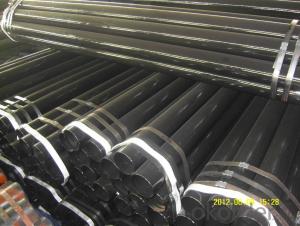

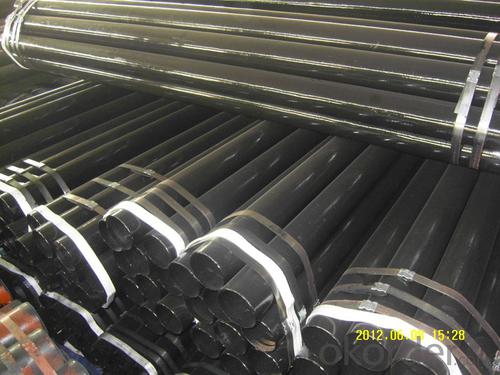

ASTM A 106 GRB cold drawn seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Thickness: | 1 - 80 mm | Section Shape: | Round | Outer Diameter: | 6 - 2020 mm |

Place of Origin: | Shandong China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Oil Pipe |

Technique: | Cold Drawn,Seamless | Certification: | API | Surface Treatment: | Copper Coated |

Special Pipe: | API Pipe | Alloy Or Not: | Is Alloy | Grade: | 20#,45#,15CrMo,10CrMo910,13CrMo44,12Cr2Mo,12CrMo195,12Cr1MoVG,API J55,API K55,St37,St52,St35.8,St37-2,St42-2,10#-45#,Cr-Mo alloy,API J55-API P110,ST35-ST52 |

Standard: | GB 5310-1995,GB 3087-1999,GB/T 8163-1999,GB/T 8162-1999,GB/T 9711.1-1997,GB 13296-2007,GB/T 3091-2001,GB/T 3089-1982,GB/T 17396-1998,GB/T 12771-2000,GB |

Packaging & Delivery

Packaging Detail: | Export packing or as your demand. |

Delivery Detail: | depend on the QTY you need. |

Specifications

cold drawn seamless steel pipes

1)Grade:20#,45#,16Mn C20,C45,St52 A106 A53

2)OD10.3mm--1219mm WT SCH5S--XXS

3)High quality

Standard | Steel Grade | Standard Name | Dimension |

No | Range | ||

EN 10208 | L210GA,L235GA,L245GA,L290GA, | Steel Pipes for Pipelines for | 33.7-1626mm |

L360GA,L245NB, L290NB,L360NB, | Combustible Fluids | ||

L415NB, L360QB, LI15QB,L450QB, | |||

L485QB,L555QB | |||

EN 10210 | S235JRH,S275JOH,S275J2H,S355JOH, | Hot Finished Structural | 21.3-1219mm |

S355J2H,S355K2H,S275NH,S275NLH, | Hollow Sections of Non-alloy | ||

S355NH,S355NLH,S420NH,S420NLH, | and Fine Grain Steels | ||

S46INH,S460NLH | |||

EN 10216-1 | P195TRI,P195TR2,P235TR1, | Seamless Steel Tubes for | 10.2-711mm |

P235TR2, P265TR I, P265TR2 | Pressure Purposes-1- | ||

Non-alloy Steel Tubes with | |||

Specified Room Temperature | |||

Properties | |||

EN 10216-2 | P195GH, P235GH, P265GH, | Seamless Steel Tubes for | 10.2-711mm |

20MnNb6,16Mo3, 8MoB5-4, | Pressure Purposes-2: | ||

14MoV6.3, 10CrMo5.5,13CrMo4-5, | Non-alloy and Alloy Steel | ||

10CrMo9-10, 11CrMo9.10, | Tubes with Specified Elevated | ||

25CrMo4,20CrMoV13-5-5, | Temperature Properties | ||

15 NiCuMoNB-6-4,X11CrMo5+1, | |||

X11CrMo5+NTI,X11CrMo5+NT2, | |||

X11CrMo9.1+1, X11CrMo9.1+NT, | |||

X10CrMoVNb9-l, X20CrNiV11-1 | |||

EN 10216-3 | P275NL I,P275NL2, P355N,P355NH, | Seamless Steel Tubes for | 10.2-711mm |

P355NL1,P355NL2,P460N,P460NH, | Pressure Purposes-3: | ||

P460NL1,P460NL2,P620Q,P620QH,P620QL, | Alloy Fine Grant Steel Tubes | ||

P690Q,P690QH,P690OL1,P690QL2 | |||

EN10216-4 | P215NL,P255QL,P265NL, | Seamless Steel Tubes far | 10.2-711mm |

26CrMo4.2,11MnNi5-3,13MnNi6-3, | Pressure Purposes-4: | ||

12Nil4,Xl2Ni5,X10Ni9 | Non-alloy aid Alloy Steel | ||

Tubes with Specified Low | |||

Temperature Properties | |||

EN 10224 | L235, L275, L355 | Non-alloy Steel Tubes and | 26.9-2743mm |

Fittings for the Conveyance of | |||

Water and Other Aqueous | |||

Liquids | |||

EN 10297-1 | E235,E275,E315,E355,E470, | Seamless Circular Steel Tubes | 26.9-610mm |

E275K2,E355K2,E420J2,E460K2, | for Mechanical mid General | ||

E590K2,F730K2 C22E,C35E,C45E,C60E, | Engineering Purposes-1: | ||

38Mn6,41Cr4,25CrMo4,30CrMo4, | Non-alloy and Alloy | ||

34CrMo4,42CrMo4,36CrNiMo4, | Steel Tubes | ||

30CrNiMo8,4lNiCrMo7-3-2 | |||

EN 10305-1 | E215,E235,E355 | Steel Tubes For Precision | 4-260mm |

Applications-1: | |||

Seamless Cold Drawn Tubes | |||

EN 10305-4 | E215,E235,E355 | Steel Tubes for precision | 4-80mm |

Applications-4: | |||

Seamless Cold Drawn Tubes | |||

for Hydraulic mid Pneumatic | |||

Power Systems |

- Q: What are the different methods of pipe protection for steel pipes?

- There are several methods of pipe protection for steel pipes. These include corrosion-resistant coatings such as epoxy or polyethylene, cathodic protection systems, which use sacrificial anodes or impressed current to prevent corrosion, wrapping the pipes with protective tape or shrink sleeves, and using corrosion inhibitors to prevent the formation of rust. Additionally, proper installation practices, regular inspections, and maintenance can also contribute to pipe protection.

- Q: Can steel pipes be used for brewery installations?

- Yes, steel pipes can be used for brewery installations. Steel pipes are commonly used in breweries for various applications such as transferring liquids, connecting equipment, and supporting structures. They are durable, resistant to corrosion, and can withstand high temperatures and pressures, making them suitable for brewery installations.

- Q: What is the difference between steel pipes and PVC-M pipes?

- Steel pipes are made from a strong and durable material, steel, and are commonly used for carrying high-pressure fluids or in industrial applications. On the other hand, PVC-M pipes are made of a plastic material called polyvinyl chloride modified, which offers good flexibility and resistance to corrosion. PVC-M pipes are typically used in low-pressure applications such as domestic plumbing, irrigation, or drainage systems.

- Q: How are steel pipes used in the automotive exhaust system?

- Steel pipes are used in the automotive exhaust system to channel the exhaust gases from the engine to the rear of the vehicle. These pipes are durable and resistant to high temperatures and corrosive elements, making them ideal for withstanding the intense heat and harsh conditions of the exhaust system. Additionally, steel pipes are often used to reduce noise and vibrations generated by the engine, improving the overall performance and comfort of the vehicle.

- Q: Can steel pipes be used for plumbing?

- Yes, steel pipes can be used for plumbing. They are commonly used in commercial and industrial applications due to their durability and strength. However, they are less common in residential plumbing due to their higher cost and the availability of alternative materials such as copper and PVC.

- Q: How are steel pipes used in the construction of offshore oil rigs?

- Steel pipes are used in the construction of offshore oil rigs primarily for the transportation of oil and gas. These pipes are used to connect the wells drilled in the seabed to the surface facilities on the rig. They are also utilized for the circulation of drilling fluids, which help maintain stability and cool down the drilling equipment. Additionally, steel pipes are used to construct the rig's structural components like risers, conductors, and caissons, providing strength and support in the harsh offshore environment.

- Q: Can steel pipes be coated for additional protection?

- Yes, steel pipes can be coated with various materials to provide additional protection against corrosion, abrasion, and other environmental factors. Coatings such as epoxy, polyethylene, and zinc can be applied to enhance the durability and lifespan of steel pipes, making them suitable for diverse applications in different industries.

- Q: Are steel pipes resistant to UV radiation?

- Yes, steel pipes are generally resistant to UV radiation. UV radiation is known to cause damage to materials over time, such as fading, discoloration, and degradation. However, steel pipes are typically coated with protective layers, such as paint or galvanization, which help to shield them from UV radiation. These coatings act as a barrier, preventing the direct exposure of steel to UV rays and minimizing the potential for damage. Additionally, the inherent properties of steel, including its strength and durability, make it less susceptible to the effects of UV radiation compared to other materials like plastics or rubber. However, it is important to note that prolonged exposure to intense UV radiation can still have some impact on steel pipes, such as slight discoloration or surface degradation. Regular maintenance and inspection are recommended to ensure the continued performance and longevity of steel pipes in outdoor or UV-exposed environments.

- Q: How are steel pipes used in the agriculture sector?

- Steel pipes are commonly used in the agriculture sector for various purposes, such as irrigation systems, drainage systems, and structural support for farm buildings and infrastructure. They are also used for conveying water, chemicals, and other fluids, as well as for constructing fencing and livestock enclosures. Moreover, steel pipes are utilized in the construction of machinery and equipment essential for farming operations.

- Q: How are steel pipes tested for leakage?

- Steel pipes are typically tested for leakage using various methods such as hydrostatic testing, ultrasonic testing, or dye penetrant testing. Hydrostatic testing involves pressurizing the pipe with water or another suitable liquid to a predetermined level and checking for any pressure drop over a specific period of time, indicating potential leakage. Ultrasonic testing utilizes high-frequency sound waves to detect any defects or cracks in the pipe wall that may cause leakage. Dye penetrant testing involves applying a colored liquid to the surface of the pipe, which seeps into any cracks or openings, making them easily visible under specific lighting, thus identifying potential leaks.

Send your message to us

ASTM A 106 GRB cold drawn seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords