Aseptic Pulp filling equipment

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Equipment profile:

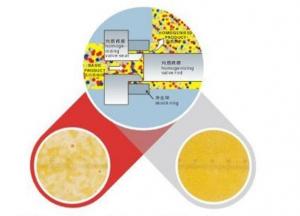

GXGF3020206typepulp 4-in-1 fillingmachine is aset of rinsing(disinfectantrinsing, pure water rinsing), pulpfilling,juicefilling and cappingin oneof the moderate (high)temperaturefilling machine, pulp,juice separately fillingsolvethe problem of unevencontent.

Host fully enclosed sealed windows, filling area and rinsing area isolated, filling part 100 cleanto ensure that the environment in the filling area to reach the desired temperature and filling requirements.

Bottle conveying adopts activeclamptransition, to reduce the adjustment and operation to the machine when changing bottle shape under the circumstance of keep the bottle mouth.

Host usingSEWreducer and couplinginteractiontransfer powerto ensure thesmoothoperation.

Technical parameters:

Model | GXGF30-20-20-6 |

Capacity | 8000BPH(Φ38Bottle neck)/7000BPH(Φ28Bottle neck) |

Number of working station | rinsing 30、pulp filling 20、juice filing20、capping 6 |

Main machine power | 6.5KW |

Air consumption | 0.8M3 |

Air pressure | 0.7 M3 |

Suitable bottle | Diameter Φ50mm-Φ120mm Bottle height 160mm-330mm |

Dimension | 6940mmX3210mmX2800 |

Weight | 7000Kg |

- Q: Filling machine installation precautions

- After the machine out of the box, first check the random technical information is complete, the machine is damaged in the transport, in order to solve.

- Q: What is the heat sealing method of hot pressing sealing machine?

- It is widely used in a variety of plastic bags of heat sealing.

- Q: What are the processes?

- The flocculant is stirred by the pump impeller and then mixed with the fine solid particles in the raw water and the micro-flocculation reaction of the colloidal substance is carried out. The flocculant is stirred by the pump impeller,

- Q: What is reverse osmosis equipment?

- and then out of the concentrated water effluent, so as to achieve separation and purification purpose.

- Q: What is the difference between a lubricating oil filling machine and an oil filling machine?

- Oil is a kind of oil is contained in the relationship between the oil are liquid is generally used only to

- Q: Equipment characteristics of water treatment equipment

- Production of pure water quality, health indicators ideal.

- Q: The circuit principle of the sealing machine

- When the switch K is closed, the AC power by R1, R2 buck, diode D1 rectifier.

- Q: What are the brands of imported disinfection equipment?

- Air and objects on the surface disinfection of the sterilizer more: ozone, ultraviolet, air purifier and many other options.

- Q: What is the price of the filling machine?

- Screw, measuring plate, etc. easy to disassemble, easy to install and debug.

- Q: What are the main water treatment equipment used in the industry?

- Water treatment equipment, on the application of the point of view, can be divided into water purification function of drinking water treatment equipment, industrial production of water treatment equipment, sewage treatment (plant) water treatment equipment, wastewater reuse in the water

Send your message to us

Aseptic Pulp filling equipment

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords