Bottle unscrambler for Fiilling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

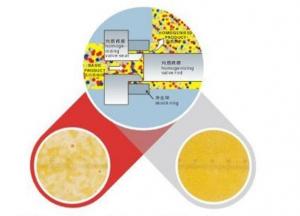

Equipment overview

Bottle unscrambler--- LP-12

LP-12-type Unscrambler is the introduction of foreign advanced technology, the need for development, development of the row of bottles apparatus having a domestic leading level of China's beverage filling equipment according to the direction of the high-speed development.

Main features of equipment

The main motor reducer using a torque limiting mechanism to prevent damage to the machine when a failure occurs.

Using two rows of bottles of elected bodies, to ensure that each station has a bottle off the bottle, the bottle to improve efficiency.

Using hanging bottle conveying duct, to avoid tipping the bottle at the time of delivery.

Excluding agency has broken bottle.

Bottle with a card detector, automatic shutdown and alarm card bottle.

Has no bottle detector for issuing work signal to hoist, hoist will automatically add the bottle.

Bottle conveying ducts equipped with photoelectric switch for start-stop control Unscrambler.

Unscrambler has a grease nipple can be easily to gears, bearings and cam filling oil.

A maintenance door and mold replacement door.

The main electrical components (inverter, PLC, photoelectric switches, relays) are used MITSUBISHI, OMRON, SIEMENS and other components.

Gas system are imported products.

Technical Parameters

Bottle unscramble--- LP-12

Working station | 12 |

Capacity | 6000BPH |

Max capacity | 8000BPH |

Air pressure | 0.7MPa |

Air consumption | 1.5M3/min |

Adaptation bottle size | Diameter 50-90, height 165-290 |

Main motor power | 1.5KW |

Lifting motor power | 0.75KW |

Dimension | Φ1660×2060(Diameter×height) |

Weight | 2000KG |

Bottle unscramble--- LP-14

Working station | 14 |

Capacity | 8000BPH |

Max capacity | 10000BPH |

Air pressure | 0.7MPa |

Air consumption | 1.5M3/min |

Adaptation bottle size | Diameter 50-90, height 165-310 |

Main motor power | 1.5KW |

Lifting motor power | 0.75KW |

Dimension | Φ2200×2340(Diameter×height) |

Weight | 3200KG |

Bottle unscramble--- LP-16

Working station | 16 |

Capacity | 10000BPH |

Max capacity | 12000BPH |

Air pressure | 0.7MPa |

Air consumption | 1.5M3/min |

Adaptation bottle size | Diameter 50-90, height 165-290 |

Main motor power | 1.5KW |

Lifting motor power | 0.75KW |

Dimension | Φ2200×2340(Diameter×height) |

Weight | 3200KG |

Bottle unscramble--- LP-18

Working station | 18 |

Capacity | 18000BPH |

Max capacity | 20000BPH |

Air pressure | 0.7MPa |

Air consumption | 2M3/min |

Adaptation bottle size | Diameter 50-96, height 165-310 |

Main motor power | 3KW |

Lifting motor power | 0.75KW |

Dimension | Φ2640×2340(Diameter × height) |

Weight | 4200KG |

Bottle unscramble--- LP-21

Working station | 21 |

Capacity | 22000BPH |

Max capacity | 25000BPH |

Air pressure | 0.7MPa |

Air consumption | 2M3/min |

Adaptation bottle size | Diameter 50-96, height 165-310 |

Main motor power | 3KW |

Lifting motor power | 0.75KW |

Dimension | Φ3020×2650(Diameter × height) |

Weight | 4600KG |

Bottle unscramble--- LP-24

Working station | 24 |

Capacity | 28000BPH |

Max capacity | 30000BPH |

Air pressure | 0.7MPa |

Air consumption | 2M3/min |

Adaptation bottle size | Diameter 50-96, height 165-310 |

Main motor power | 4KW |

Lifting motor power | 0.75KW |

Dimension | Φ3400×2650(Diameter × height) |

Weight | 5000KG |

- Q: Water treatment conductivity filter how much normal?

- Are you talking about the conductivity of reverse osmosis equipment?

- Q: Liquid Filling Machine Optional Accessories

- A. Needle filling head: for small caliber bottles and hose packaging products filling.

- Q: The characteristics of the filter device

- At the same time, the amount of water consumed during backwashing is very small at a flow rate of 300 m3 / h.

- Q: Filling machine out of a two out of six what six mean

- said how many heads, or how many bottles per hour production

- Q: Filling machine instructions

- 5, the machine must be kept clean, the machine is strictly prohibited oil, liquid or glass debris, so as to avoid damage to the machine, it must:

- Q: Sealing machine operating procedures

- 4, pushed into the container to be closed to normal operation.

- Q: What is self-cleaning filter

- In the filtration process, the fine filter of the inner layer of impurities gradually accumulate, its inside and outside on both sides of the formation of a pressure.

- Q: What is uht sterilization?

- Common UHT equipment are: coil sterilization machine, inverted bottle sterilizer and plate sterilization machines and so on.

- Q: Water Treatment Equipment Water Regulator Anti - scaling Technology

- 1.1 Install the connection pipe for the well and the equipment

- Q: Low temperature dry sterilization to keep nutrients

- Microwave heat effect of the rapid warming and non-thermal effect of the dual sterilization effect, compared to conventional thermal drying, sterilization at a relatively low temperature and a short period of time can get the required drying, sterilization effect.

Send your message to us

Bottle unscrambler for Fiilling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches