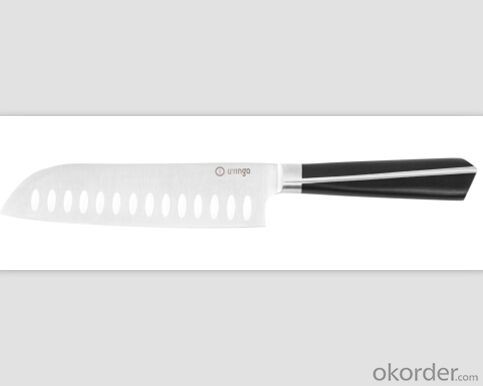

Art no. HT-KP1007 Stainless steel knife set

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Set includes:

1 × utility knife

1 × carving knife

1 × chopping knife

High-carbon stainless steel blade holds a superior sharp edge

High quality stainless steel,tool vertical tough strong corrosion resistance

Comfortable grip handle for balance and control

Many other designs are available

Customized orders are accepted

Features:

No slot foldable magnetic wooden knife block

Seamless welding technique

Fashionable and comfortable handle design

Multifunction kitchen knife set meets customer's needs during cooking

Stainless steel knife blade with logo printed

Hard enough and sharp for cutting food

Easy to clean and save space

Fashion designnable design

Customized designs are welcome

OEM orders are welcome

Product advantages:

Wear resistant & extremely durable

Deathly sharp & stay sharp for years

Easy to clean to prevent bacteria growth

Blade high in density, chemically inert will not rust and do not react with acidic, food keep its original taste. No metal taste and smell

- Q: What cutting properties should be provided for the cutting parts

- 1 hardness is high, its hardness is much greater than the processed material;2 red to high;3 good wear resistance;4 better processing technology

- Q: What are the commonly used tool materials

- The common tool material: high-speed steel, cemented carbide (including cermets), ceramic, PCBN (cubic boron nitride), PCD (PCD), its hardness is a hard, so in general, the cutting speed is higher than the one.

- Q: Are all self locking knives controlled? The knife is small again?

- You know, this is in China, the tube is not the document is not the final say, it is the banditsAccording to the truth below 8cm is not the knife knives

- Q: What tools are used for machining stainless steel

- The main tool is selected angle. It is the processing difficulty. Good toughness red hardness. The tool wear and poly. Choose a sharp cutting tool is good. High speed steel and hard alloy cutter can be, the main attention chipbreaker and tool angle.

- Q: What is the classification of the hardness level?

- 1, the hardness of cemented carbide tools generally between HRA89.5~92.8;2, the hardness of high speed steel is generally between HRC62~65;3, super hard high speed steel hardness between HRC69~70;

- Q: YG813 carbide tools can be intermittent turning stainless steel? How much is the cutting speed?

- Good abrasion resistance, high bending strength and bond resistance. Suitable for processing high temperature alloy, stainless steel, high manganese steel and other materials

- Q: How to select NC milling cutter

- When the tool is selected, the size of the tool is adapted to the size of the workpiece being machined. In the production of plane components peripheral outline processing, often uses the cutter; milling plane, elected hard alloy cutter; processing the boss and the groove, selection of high speed steel cutter; workpiece surface or rough machining holes, take optional maize milling with carbide tips; some of the three-dimensional surface and processing variable angle outline, often uses a ball milling cutter, milling cutter, milling cutter and circular cone disc cutter.

- Q: What are the causes of tool wear and breakage?

- The tool wear is mainly divided into abrasive wear, chemical wear and so on. In general, the main reasons are different, such as abrasive wear is generally considered to be normal wear and tear, is due to the friction between the tool and the material being processed

- Q: What is the most important influence on the cutting tool?

- The roughness usually requires the feed rate to be determined, so the parameters of efficiency and economy should be calculated according to the requirements of the drawing

- Q: Woodworking engraving machine commonly used tools which?

- Taper ball end cutter, referred to as spherical cone. Is a mixture of spherical cone cone knife and knife, knife cone has the characteristics of it on the one hand, has a very small nose, on the other hand a knife features, can fine carving surface. The cone knife is often used to relief surface carving, engraving, carving and other relief image projection.Taper nose knife, knife cone taper is a mixture of bovine and bovine knife knife, knife cone has the characteristics of it on the one hand, has a small nose, fine carving and milling surface, on the other hand, has the characteristics of cownose knife, so the knife is often used in the nose taper relief surface engraving.Big head knife, in fact, the head of the cone angle larger cone knife. Mainly used for three-dimensional clearance.Drilling tool, mainly used for drilling. When the hole is relatively shallow, you can use a flat knife.

Send your message to us

Art no. HT-KP1007 Stainless steel knife set

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords