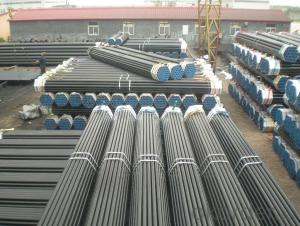

API GRADE CARBON STEEL SEAMLESS PIPES WITH FACTORY PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details

Thickness: | 2.0 - 85 mm | Section Shape: | Round | Outer Diameter: | 17 - 914.4 mm |

Secondary Or Not: | Non-secondary | Application: | Oil Pipe | ||

Technique: | Hot Rolled | Certification: | API | Surface Treatment: | VARNISH PAITING |

Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | END: | PLAIN,BEVELED OR THREADED |

OKorder is offering high quality Seamless Steel Alloy Pipe at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel pipe, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Seamless Steel Alloy Pipe is ideal for long distance oil, gas, and natural gas pipelines on land and offshore. They can also be applied in construction projects, offshore platforms, power stations, the petrochemical industry and municipal construction.

Product Advantages:

OKorder's Steel Pipe is durable, resists corrosion and is recyclable.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Professional Service

· Competitive pricing

Product Pictures:

- Q: What is the maximum diameter of steel pipes?

- The maximum diameter of steel pipes can vary depending on the specific needs and requirements of a project. However, steel pipes are commonly available in diameters ranging from 1/8 inch to 72 inches or even larger.

- Q: Does seamless steel tube have a bend of 135 degrees?

- In engineering, it is usually marked as "45 elbow" and has no "135" mark. The angle of the elbow is acute, so there will be no more than 90 degrees elbow.Elbow is a common connecting pipe used in plumbing and heating. It is used for the connection of the bend of pipe, and is used to change the direction of pipe.

- Q: What is hot rolled steel pipe? What is a cold drawn steel tube?

- General use seamless steel tube: is with 10, 20, 30, 35, 45# and other high-quality carbon steel, 16Mn, 5MnV and other low-alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other alloy steel hot-rolled or cold rolled. Seamless tubes made of low carbon steel, such as 10, 20, are mainly used for fluid delivery pipelines. 45. Seamless tubes made of medium carbon steel such as 40Cr, used for the manufacture of mechanical parts, such as parts of automobiles and tractors. General use of seamless steel pipe to ensure the strength and flattening test. Hot rolled steel tubes are delivered in hot rolling or heat treated conditions. Cold rolled in heat treated state.

- Q: How are steel pipes used in the manufacturing of railways?

- Steel pipes are commonly used in the manufacturing of railways for various purposes. They are used for the construction of railway tracks, providing a strong and durable foundation. Steel pipes are also used in the manufacturing of railway bridges and tunnels, ensuring structural integrity and support. Additionally, steel pipes are utilized for the transportation of fluids and gases within the railway system, such as fuel or water.

- Q: Can steel pipes be used for oil wells?

- Yes, steel pipes can be used for oil wells. Steel pipes are commonly used in the oil and gas industry due to their strength, durability, and resistance to corrosion. They are able to withstand the high pressures and temperatures that are encountered in oil well drilling and production. Steel pipes are also able to transport oil efficiently and safely from the well to the surface, making them a preferred choice for oil well infrastructure. Additionally, steel pipes can be easily welded and threaded, allowing for easy installation and maintenance in oil well applications.

- Q: What are the common factors affecting the flow capacity of steel pipes?

- The common factors affecting the flow capacity of steel pipes include the diameter of the pipe, the length and roughness of the pipe, the viscosity of the fluid being transported, and the overall pressure drop across the pipe.

- Q: How are steel pipes used in the pharmaceutical industry?

- Steel pipes are commonly used in the pharmaceutical industry for various purposes such as transporting fluids, gases, and chemicals, as well as providing structural support for equipment and machinery. They are utilized in pharmaceutical manufacturing processes, including the transfer of raw materials, disinfection, and sterilization procedures, and the distribution of pharmaceutical products. Steel pipes ensure the safe and hygienic transfer of substances, maintaining the integrity and quality of pharmaceutical products throughout the production and distribution chain.

- Q: What are the different methods of welding steel pipes?

- There are several different methods of welding steel pipes, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW). Each method has its own advantages and is suitable for different applications and pipe sizes.

- Q: How do you join steel pipes together?

- Steel pipes can be joined together using various methods, including welding, threading, and using mechanical couplings.

- Q: What is ND steel pipe?

- ND steel 09CrCuSb steel is currently the most ideal "resistance to sulfuric acid dew point corrosion in steel (ND steel, ND steel, 09CrCuSb steel, 09CrCuSb steel), ND steel is widely used in the manufacture of economizer, served in the high sulfur content in flue gas of air preheater, evaporator and heat exchanger equipment for resist sulfur smoke gas dew point corrosion.

Send your message to us

API GRADE CARBON STEEL SEAMLESS PIPES WITH FACTORY PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords