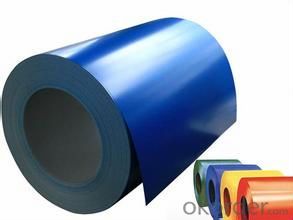

anto acid and alkali prepainted steel coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Dimensions: | Thick:0.16mm-1.0mm | Grade: | Thin steel SGCC DX51D Carbon steel |

| Application: | construction, container building | Shape: | Rolls | Alloy Or Not: | Non-alloy |

| Width: | 1000mm | Weigth/roll: | 4.5tons | Zinc coating: | 40g/sqm |

| Thickness: | 0.4mm |

Packaging & Delivery

| Packaging Detail: | Waterproofing PE film Iron strip |

| Delivery Detail: | 20 days |

Specifications

Anti corrossion prepainted steel coil

ASTM, GB, CE, GOST certified

SPCC DX51D steel base

Ship to Russia, Malaysia, Brazil

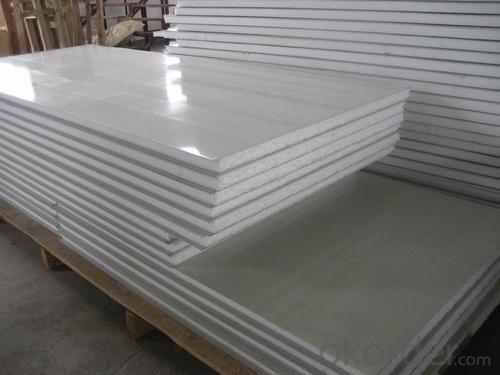

Prepainted Steel Sheet

Product Introduction:

Color coated steel sheet is a novel precoated band steel product which rapidly develops internationally in the recent thirty years. It is made by performing processes such as chemical pretreatment, primary coating and fine coating on a high-speed continuous operating unit. The color coated steel sheet has the advantages of excellent decorativeness, formability, corrosion resistance and environment friendliness, strong adhesive force of the coating, and long-time color freshness. Achieving good economic benefits such as substituting steel for wood, efficient construction, energy saving, pollution prevention, etc., it has become an ideal material for manufacturing building sheets, external decorative materials, home appliances and electric appliances at present.

Under the philosophy of “Vigoriously Developing Enterprise by Technology”, the company adopts American direct-fired heating technology, greatly reducing energy consumption and reducing cost; the roller coater adopts the most advanced French technology on the world, and the plant construction adopts high-cleanliness sealing method, meeting the requirements of dust-free production and ensuring product quality; to meet the demand of the market on high-end color-coated sheets, the company has increased three-color printing process, which meets the demand of high-end users. At present, most domestic sheets are ordinary color-coated sheets, so that high-grade color-coated sheets with high technical content have wide market prospect in China.

Product Specification:

Item | Norminal Size/mm | |

Norminal Thick | 0.15-1.2 | |

Norminal Width | Steel Sheet and Strip | 1000-1250 |

Slit Wide Strip | <600 | |

Norminal Length | Steel Sheet | 1000-8000 |

Steel Strip and Silt wide strip | 610/508 | |

- Q: 7850kg/cu.m density is typical for all type of steel? like reibar, I- beam and so on

- 90% of the steels used today are plain mild carbon steels consisting of iron with less than 1% carbon content and as such have a density of about 7750 kg/cubic meter. Some special steels which have a significant percentage of alloying elements such as chrome or manganese or other elements will have greater density bringing the steel up to about 8000 kg / cubic meter. There are a greater many factors influencing the exact density of a steel. Even for steels of exactly the same content of iron , carbon and other alloying elements, there may be a difference ( very small mind you ) in density due to work hardening. The difference in this case is due to movement of dislocations which become locked in the grain boundaries and this forms a more dense crystal structure. For this same reason, the theoretical density of steel (which does not take into account dislocations) is greater than the measured density of steel.

- Q: I bought stainless steel appliances a year ago. I have two kids who like to put their hands all over the fridge and they always leave dirty marks all over it. I bought stainless steel cleaner but it doesn't do a good enough job. Anyone know any other cleaning remedies?

- All the stainless steel cleaners I've tried are fine for polishing, but they don't clean anything. A damp microfiber towel (the kind with loops like terry cloth) does a good job. You might be able to use plain water because the cloths are so good. Or mix up some dish soap in water and wet the towel with that. You can use windex if you want something more convenient.

- Q: How are steel coils labeled for identification?

- Steel coils are typically labeled for identification using tags or stickers that contain important information such as the grade, size, weight, and production details of the coil. Additionally, some coils may also have unique identification numbers or barcodes for easier tracking and inventory management.

- Q: Will a 1 inch thick A36 steel target withstand a 7.62x54r round?

- It sure will. It will also be a major pain in the back side to move it to where you can safely shoot at it.

- Q: How are steel coils inspected for paint adhesion?

- Various methods and techniques are utilized to inspect the adhesion of paint on steel coils. One commonly employed method is the tape test, which involves pressing adhesive tape onto the painted surface and swiftly removing it. The amount of paint that is lifted off by the tape is then examined to assess the adhesion. If the paint adheres well to the steel, only a minimal amount of paint will be removed. Another method employed is the crosshatch adhesion test. This test entails making parallel cuts on the painted surface using a sharp blade, creating a crosshatch pattern. A piece of adhesive tape is then applied over the cuts and rapidly pulled off. The evaluation of the paint that is removed from the crosshatched area determines the adhesion. Furthermore, a visual inspection is frequently conducted to evaluate the overall appearance and adhesion of the paint. Inspectors search for any indications of cracking, peeling, or bubbling, which may indicate poor adhesion. They also check for any areas where the paint may have chipped or flaked off. Moreover, various laboratory tests can be conducted to assess the paint adhesion on steel coils. These tests may include techniques like the pull-off test, where a specialized device is used to measure the force required to remove a small section of the paint from the surface. Other tests may involve subjecting the painted surface to extreme temperature or humidity conditions to assess the paint's performance under different environmental factors. In summary, a combination of visual inspections, tape tests, crosshatch adhesion tests, and laboratory tests are employed to thoroughly inspect steel coils for paint adhesion. These tests ensure that the paint adheres effectively to the steel surface, resulting in a durable and long-lasting finish.

- Q: What are the common coil handling equipment used in the industry?

- Some common coil handling equipment used in the industry are coil cradles, coil reels, coil straighteners, coil feeders, and coil transfer cars. These tools are essential for safe and efficient handling of coiled materials during various manufacturing processes.

- Q: is red steel any good??????? not sure im really impressed but im not really into fighting games but it looks cool.... so whats your views guys???????anyone bored of smooth moves yet?anyone think the new sonic is bit cra ppy !!!!!!!!!!! darn them any new goooood games coming oput on the wii??

- red okorder . I think it deservs a rental

- Q: How long does the coating on steel coils last?

- The longevity of the coating on steel coils can vary depending on a variety of factors including the type of coating, environmental conditions, and usage. However, with proper maintenance and protection, a well-applied coating can typically last anywhere from 10 to 30 years.

- Q: I know that steel wool is coated with... something... that protects it from rusting. I need to know what that is, and how to get it off.

- spun steel fibers have a microscopic coating of oil to prevent them from rusting. Rusting steel wool wouldn't sell very well. I would think that removing this oil could be accomplished with any good degreaser, like brake cleaner or the like. However, I've never tried this before. In science class they perform experiments by removing the oil with vinegar. After wringing out the steel wool pad, it is wrapped around a thermometer and placed in a sealed jar. After a few minutes the temperature rises because of the chemical reaction that takes place when four atoms of iron react with three atoms of oxygen and create two atoms of iron oxide - RUST! You can unwittingly recreate this experiment by using steel wool in the process of removing one or more layers of finish from a piece of furniture Hope this helps

- Q: How are steel coils inspected for quality control purposes?

- Steel coils are inspected for quality control purposes through a series of tests and checks. This may include visual inspection to detect any surface defects, such as scratches or dents. Additionally, measurements and tests are conducted to ensure dimensional accuracy, such as thickness, width, and weight. Non-destructive testing methods, such as magnetic particle testing or ultrasonic testing, are also employed to identify any internal defects, like cracks or voids. These comprehensive inspections help ensure that steel coils meet the required quality standards before they are used in various applications.

Send your message to us

anto acid and alkali prepainted steel coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords