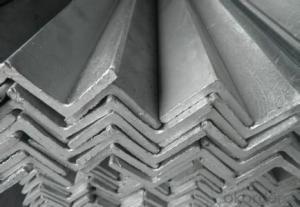

Angle Steel Hot Rolled ASTM A36 and GB Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1 What makes stainless steel stainless?

A1 Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q2: How do you package the angle steel when shipping?

A2: All goods are packed in bundles with steel strips and shipped by container or break bulk.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: Can steel angles be used in the construction of pedestrian bridges?

- Indeed, the utilization of steel angles is feasible in the construction of pedestrian bridges. Owing to their robustness and longevity, steel angles are widely employed in construction. They serve the purpose of offering structural support and stability to pedestrian bridges, while also enabling the creation of frames, beams, and trusses. The adaptability in design and construction is facilitated by the ease of welding or bolting steel angles together. Moreover, steel angles can be galvanized or coated, amplifying their resistance to corrosion and rendering them suitable for outdoor applications like pedestrian bridges. All in all, steel angles emerge as a versatile and dependable option for the construction of pedestrian bridges.

- Q: What are the different testing methods used for quality control of steel angles?

- There are several testing methods used for quality control of steel angles. These include visual inspection, dimensional measurements, ultrasonic testing, magnetic particle inspection, and load testing. Visual inspection involves visually examining the steel angles for any surface defects or imperfections. Dimensional measurements ensure that the angles meet the specified size and shape requirements. Ultrasonic testing uses sound waves to detect any internal flaws or discontinuities in the material. Magnetic particle inspection involves applying a magnetic field to the angles and using magnetic particles to identify any surface cracks or defects. Lastly, load testing involves subjecting the angles to a predetermined load to determine their strength and structural integrity. These testing methods help ensure that the steel angles meet the required quality standards.

- Q: How do steel angles compare to other structural materials?

- Steel angles are highly versatile and widely used in construction due to their strength, durability, and cost-effectiveness. Compared to other structural materials like wood or concrete, steel angles offer superior strength-to-weight ratio, allowing for lighter structural components without compromising structural integrity. Additionally, steel angles are resistant to fire, pests, and moisture, making them ideal for long-lasting and low-maintenance structures. Overall, steel angles are a reliable and efficient choice for various structural applications.

- Q: Can steel angles be used in load-bearing columns?

- Yes, steel angles can be used in load-bearing columns. Steel angles are often used in construction for their strength and durability. They provide structural support and can be used to reinforce load-bearing columns. The angle shape of the steel allows for greater stability and load-bearing capacity compared to other materials. Steel angles are commonly used in the construction of buildings, bridges, and other structures where load-bearing columns are required.

- Q: Are steel angles suitable for high-temperature environments?

- No, steel angles are not suitable for high-temperature environments as they tend to lose their structural integrity and strength at elevated temperatures.

- Q: Can steel angles be painted or coated after installation?

- Yes, steel angles can be painted or coated after installation. Painting or coating steel angles after installation can provide additional protection against corrosion and enhance their aesthetic appeal. Prior to painting or coating, it is important to clean and prepare the surface by removing any dirt, rust, or contaminants. This can be done through techniques such as sandblasting, wire brushing, or using chemical cleaners. Once the surface is clean and dry, a suitable primer can be applied to promote adhesion and prevent corrosion. After the primer has dried, a final coat of paint or coating can be applied using a brush, roller, or spray. It is essential to choose a paint or coating that is specifically designed for steel and offers the desired level of protection and durability.

- Q: What are the different types of steel angles used in bridge construction?

- There are several types of steel angles commonly used in bridge construction. These angles play a crucial role in providing structural support and stability to the bridge. 1. Equal Leg Angles: Equal leg angles, also known as L-shaped angles, have two legs of equal length that form a 90-degree angle. These angles are used in bridge construction to provide support and reinforcement to the bridge components. 2. Unequal Leg Angles: Unequal leg angles, as the name suggests, have two legs of different lengths that form a 90-degree angle. These angles are commonly used in bridge construction to accommodate specific design requirements and support varying loads. 3. Bulb Angles: Bulb angles are special types of angles that have a bulb-shaped leg. These angles are used in bridge construction to provide additional strength and rigidity to the bridge structure, particularly in areas where high stress or heavy loads are anticipated. 4. Inverted Angles: Inverted angles are similar to equal leg angles, but the orientation is inverted, with the longer leg on the bottom. These angles are commonly used in bridge construction to provide additional support and stability, especially in situations where the bridge needs to withstand lateral forces. 5. Fillet Welded Angles: Fillet welded angles are angles that are joined together using fillet welds. These angles are used in bridge construction to create strong and durable connections between different bridge components, ensuring structural integrity and stability. Each type of steel angle has its unique properties and advantages, making them suitable for specific applications in bridge construction. The selection of the appropriate angle type depends on factors such as load requirements, span length, design specifications, and structural considerations. Professional engineers and designers carefully assess these factors to determine the best type of steel angle to be used in a specific bridge construction project.

- Q: Can steel angles be used for outdoor applications?

- Indeed, outdoor applications can make use of steel angles. Fashioned from a robust and enduring material, steel angles prove themselves apt for a multitude of outdoor endeavors. Frequently employed in construction, infrastructure, and engineering ventures necessitating structural support or reinforcement, steel angles endure inclement weather conditions, including rain, snow, and direct sunlight, without succumbing to decay or weakening. Moreover, steel angles possess the potential to be coated or treated, amplifying their ability to resist corrosion and further augmenting their appropriateness for outdoor applications. On the whole, steel angles present themselves as a dependable and adaptable option for outdoor projects requiring durability, strength, and long-term reliability.

- Q: How do steel angles perform in chemical industry applications?

- Due to their exceptional performance in corrosive environments, steel angles are extensively utilized in the chemical industry. These angles, composed of high-strength steel, demonstrate outstanding resistance to chemicals, acids, and other corrosive substances commonly encountered in the chemical industry. In the chemical industry, various chemicals are frequently handled and processed, which can lead to the corrosion and degradation of structural materials. Steel angles, with their high resistance to corrosion, offer a dependable and long-lasting solution in such environments. Additionally, steel angles provide excellent load-bearing capacity and structural stability, making them ideal for supporting heavy equipment, tanks, and platforms in chemical plants. Their versatility permits the construction of diverse structures and equipment, ensuring the safe and efficient operation of chemical processes. Steel angles can be manufactured in various sizes and shapes, allowing for effortless customization to meet specific requirements. This adaptability renders them suitable for a wide array of applications such as piping systems, storage tanks, chemical reactors, and support structures. Furthermore, steel angles are cost-effective in addition to their corrosion resistance and structural strength. They have a lengthy lifespan, necessitate minimal maintenance, and can endure extreme temperatures, pressures, and chemical exposures. This durability and low maintenance requirement contribute to the reduction of downtime and overall operating costs in the chemical industry. In conclusion, steel angles exhibit exceptional performance in chemical industry applications by offering a combination of corrosion resistance, structural strength, versatility, and cost-effectiveness. Their ability to withstand harsh chemical environments makes them an indispensable component in the safe and efficient operation of chemical processes.

- Q: Can steel angles be used in marine or underwater applications?

- Yes, steel angles can be used in marine or underwater applications. Steel angles are often used in the construction of various marine structures, such as ships, offshore platforms, and underwater pipelines. The high strength and corrosion resistance of steel make it suitable for withstanding the harsh conditions of the marine environment, including exposure to saltwater and extreme temperatures. Additionally, steel angles can be easily welded or bolted together to form a strong and durable structure, making them an ideal choice for marine and underwater applications.

Send your message to us

Angle Steel Hot Rolled ASTM A36 and GB Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords