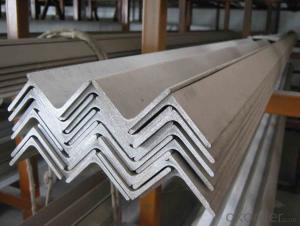

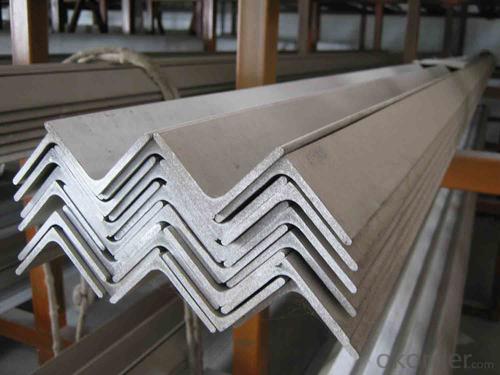

Angle Steel High Quality Hot Rolled GB Q235 Q345B ALL SIZES

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can steel angles be used in outdoor or exposed environments?

- Yes, steel angles can be used in outdoor or exposed environments. Steel angles are often made of galvanized steel, which is coated with a protective layer of zinc to prevent rusting. This makes them highly resistant to corrosion and suitable for outdoor applications. Additionally, steel angles are known for their strength and durability, making them a reliable choice for various outdoor structures, such as fences, railings, and supports. However, it is important to note that regular maintenance and inspection may be required to ensure the ongoing integrity and performance of steel angles in outdoor or exposed environments.

- Q: How do steel angles perform in terms of thermal conductivity?

- Steel angles have relatively low thermal conductivity compared to other materials. This means that they are not as efficient in conducting heat as materials such as aluminum or copper. However, steel angles still have moderate thermal conductivity, which allows them to dissipate heat to some extent. This property can be advantageous in certain applications where heat transfer needs to be controlled or balanced. Overall, while steel angles may not have the highest thermal conductivity, they still offer sufficient performance for many structural and construction purposes.

- Q: Can steel angles be used for framing or supporting exterior façade elements?

- Steel angles have the capability to be utilized in framing or supporting exterior façade elements. In the construction industry, steel angles are frequently employed due to their robustness and endurance. They offer a steadfast and dependable support system for various architectural elements, particularly exterior façade elements. Steel angles can be employed to construct windows, doors, and other openings in the exterior walls. Furthermore, they can be utilized to enhance and sustain the weight of exterior cladding materials such as stone, glass, or metal panels. Steel angles exhibit versatility and can be effortlessly customized to suit the specific requirements of the project. They are often preferred in commercial and industrial buildings where structural stability is of utmost importance.

- Q: Can steel angles be used for stairs?

- Stairs can indeed utilize steel angles. The construction industry frequently employs steel angles for a multitude of purposes, including the creation of staircases. These angles are frequently employed to provide the necessary structural support for stair treads and risers. By incorporating steel angles, stairs gain durability and stability, rendering them a favored option for both residential and commercial structures. Moreover, steel angles boast adaptability for stair construction as they can be effortlessly tailored and fabricated to meet unique design specifications.

- Q: How do steel angles compare to other materials like aluminum or wood?

- Steel angles possess several advantages over materials such as aluminum or wood. Firstly, they are renowned for their strength and durability. Steel is an exceptionally robust substance capable of withstanding heavy loads and high-pressure scenarios, rendering it ideal for structural purposes. In contrast, aluminum is comparatively weaker and less durable, making it more suitable for lightweight applications. Secondly, steel angles exhibit excellent fire resistance properties. Steel is non-combustible, meaning it does not burn or contribute to fire propagation. Conversely, wood is highly flammable and can pose a fire hazard in certain circumstances. Although aluminum has a higher melting point than wood, it does not possess the same level of fire resistance as steel. Additionally, steel angles outperform both aluminum and wood in terms of corrosion resistance. Steel can be galvanized or treated with protective coatings to prevent rust and corrosion, making it suitable for outdoor or marine applications. Although aluminum has a natural oxide layer that resists corrosion, it is still more susceptible to corrosion than steel. Wood, being an organic material, is highly vulnerable to rot and decay when exposed to moisture or insects. Another advantage of steel angles lies in their versatility. Steel can be easily fabricated and manipulated into various shapes and sizes, offering a wide range of design possibilities. While aluminum also provides some flexibility in terms of fabrication, it is generally less malleable and more prone to cracking. Wood, although relatively easy to work with, has limitations in terms of structural integrity and design flexibility. Regarding cost, steel angles are typically more economical than aluminum. Steel is widely available and has lower production costs, making it a cost-effective choice for many applications. Conversely, aluminum can be more expensive due to higher production costs and its limited availability. Depending on the type and quality, wood may vary in price but is often more affordable than steel or aluminum. In summary, steel angles provide superior strength, durability, fire resistance, corrosion resistance, versatility, and cost-effectiveness compared to materials like aluminum or wood. However, the choice of material ultimately depends on the specific application, design requirements, and budget constraints.

- Q: Can steel angles be used in sports or recreational facilities?

- Yes, steel angles can be used in sports or recreational facilities. Steel angles are commonly used in the construction of various structures, including sports facilities such as stadiums, gymnasiums, and indoor arenas. They provide strength, durability, and support for the construction of grandstands, bleachers, and other seating arrangements. Additionally, steel angles can be utilized in the fabrication of equipment and fixtures like goal posts, basketball hoops, and fencing, further demonstrating their versatility in sports and recreational settings.

- Q: Can steel angles be used in temporary or modular structures?

- Yes, steel angles can be used in temporary or modular structures. Steel angles are commonly used in construction due to their strength, versatility, and cost-effectiveness. They are often used to provide structural support and stability in various applications, including temporary or modular structures. Steel angles can be easily cut, welded, and bolted, making them suitable for assembling and disassembling temporary or modular structures. Additionally, steel angles can withstand heavy loads and provide excellent resistance against bending and twisting forces, ensuring the stability and safety of the structure.

- Q: Are there any environmental concerns related to the production or disposal of steel angles?

- There exist numerous environmental concerns in relation to the production and disposal of steel angles. To begin with, the production of steel angles necessitates substantial amounts of energy and raw materials, such as iron ore and coal. The extraction of these resources can result in detrimental effects on the environment, including habitat destruction, deforestation, and air and water pollution. Furthermore, the manufacturing process itself emits greenhouse gases and other pollutants, contributing to climate change and air pollution. Moreover, the disposal of steel angles can pose problems. Steel is not easily biodegradable and may take hundreds of years to decompose. Inadequate disposal methods, such as landfilling or incineration, can lead to the release of toxic substances and contribute to soil and water contamination. To address these environmental concerns, various measures can be implemented. Firstly, enhancing the efficiency of steel production processes can reduce energy consumption and emissions. The utilization of recycled steel in the production of steel angles can also aid in decreasing the demand for raw materials and minimizing environmental impacts. Additionally, the implementation of proper waste management and recycling programs can help minimize the environmental footprint of steel angle disposal. In conclusion, although steel angles are crucial in numerous industries and construction, their production and disposal can have significant environmental implications. It is vital to prioritize sustainable practices and technologies to mitigate these concerns and promote a more environmentally friendly approach to the production and disposal of steel angles.

- Q: How do you determine the required number of steel angles for a project?

- Determining the necessary quantity of steel angles for a project involves taking into account several factors. First and foremost, it is crucial to comprehend the project's design and specifications. This encompasses the structural prerequisites, load-bearing capacities, and any specific angles or dimensions that must be incorporated. Subsequently, the dimensions of the steel angles need to be ascertained based on the intended utilization and structural prerequisites. This entails considering the suitable length, width, and thickness of the angles for the project. Once the dimensions are established, the subsequent step involves calculating the requisite number of angles. This can be accomplished by meticulously measuring and estimating the lengths of the steel angles required in each area of the project. It is important to take into account any potential waste or additional cuts that might be necessary during the installation process. Furthermore, it is advisable to seek advice from structural engineers or professionals well-versed in steel fabrication to ensure precise calculations and to confirm that the chosen steel angles fulfill the necessary safety standards and building codes. Ultimately, determining the necessary quantity of steel angles for a project necessitates a combination of meticulous planning, accurate measurements, and professional expertise to guarantee that the project is structurally sound and meets all the necessary requirements.

- Q: Can steel angles be used for underground or subterranean structures?

- Yes, steel angles can be used for underground or subterranean structures. Steel angles provide excellent structural support and can withstand the high pressure and load-bearing requirements typically associated with underground or subterranean construction. They offer durability, strength, and flexibility, making them suitable for various applications in such environments.

Send your message to us

Angle Steel High Quality Hot Rolled GB Q235 Q345B ALL SIZES

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords