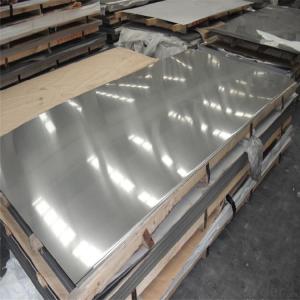

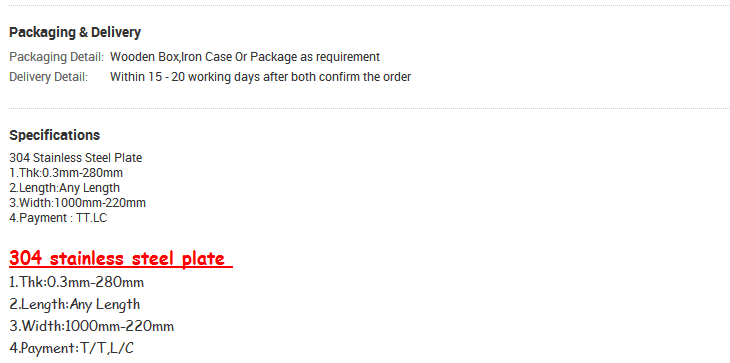

American Standard ASTM A240 304 Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Can stainless steel pipes be used for underground sewage systems?

- Yes, stainless steel pipes can be used for underground sewage systems. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions of underground environments, making it a suitable material choice for sewage systems.

- Q: Can stainless steel pipes be used for seawater applications?

- Seawater applications can indeed utilize stainless steel pipes. Stainless steel possesses exceptional resistance to corrosion and can endure the severe conditions that seawater presents, rendering it an optimal material for marine pipes. The presence of chromium within stainless steel fosters the creation of a safeguarding oxide layer on the pipe's surface, effectively preventing corrosion and ensuring its longevity. Moreover, stainless steel pipes exhibit commendable strength and can effectively handle high-pressure circumstances, thereby making them highly suitable for diverse seawater applications like desalination plants, offshore oil rigs, and shipbuilding endeavors.

- Q: Can stainless steel pipes be used for ornamental purposes?

- Yes, stainless steel pipes can be used for ornamental purposes. Stainless steel is a versatile material that offers a sleek and modern aesthetic, making it well-suited for decorative applications. The durability and corrosion resistance of stainless steel also make it an excellent choice for outdoor installations or in humid environments where other metals might deteriorate over time. Stainless steel pipes can be fabricated into various shapes and sizes, allowing for creative and visually appealing designs. They are commonly used in architectural structures, such as railings, handrails, and balustrades, as well as in decorative furniture, lighting fixtures, and artwork. Additionally, stainless steel pipes can be polished or finished in different ways to enhance their appearance and create a desired decorative effect. Overall, stainless steel pipes provide a durable and visually pleasing solution for ornamental purposes.

- Q: How is stainless steel pipe manufactured?

- Stainless steel pipe is manufactured through a process called seamless or welded pipe manufacturing. In the seamless method, a solid cylindrical billet of stainless steel is heated and pierced to form a hollow tube. This tube is then elongated and rolled to the desired diameter and thickness. Welded stainless steel pipe, on the other hand, involves the joining of two or more stainless steel plates or coils through a welding process. The resulting pipe is then further processed and finished to meet specific industry standards and requirements.

- Q: What is the difference between seamless and spiral welded stainless steel pipes?

- The main difference between seamless and spiral welded stainless steel pipes lies in their manufacturing process and structural characteristics. Seamless stainless steel pipes are produced by piercing a solid billet or bar of stainless steel and then rolling it into a hollow shape. This process does not involve any welding and results in a smooth and seamless pipe. Seamless pipes are typically used in high-pressure and high-temperature applications where strength and corrosion resistance are crucial. They are known for their uniformity, precision, and ability to withstand extreme conditions. On the other hand, spiral welded stainless steel pipes are manufactured by continuously rolling and welding a coiled strip of stainless steel. The strip is formed into a spiral shape and then welded along the seam. This process allows for the production of large diameter pipes and is more cost-effective compared to seamless pipes. Spiral welded pipes are commonly used for low-pressure and low-temperature applications, such as water and gas transportation, as they are less resistant to internal pressure and have a rougher surface compared to seamless pipes. In terms of structural characteristics, seamless stainless steel pipes have a more uniform and consistent wall thickness, resulting in enhanced strength and durability. They also have better dimensional accuracy and smoother internal surfaces, which reduces friction and improves flow efficiency. This makes seamless pipes suitable for industries such as oil and gas, petrochemicals, and power generation, where reliability and performance are paramount. On the other hand, spiral welded stainless steel pipes have a varying wall thickness due to the welding process, which can result in a weaker pipe compared to seamless ones. However, spiral welded pipes have the advantage of being able to withstand higher external pressures and bending forces due to their spiral shape. They are also easier to manufacture and can be produced in longer lengths, reducing the need for additional joints and connections. In conclusion, the choice between seamless and spiral welded stainless steel pipes depends on the specific requirements of the application. Seamless pipes offer superior strength, precision, and corrosion resistance, making them suitable for high-pressure and high-temperature applications. On the other hand, spiral welded pipes are more cost-effective, can be produced in large diameters, and are suitable for low-pressure and low-temperature applications.

- Q: How do stainless steel pipes compare to HDPE pipes?

- When comparing stainless steel pipes to HDPE pipes, there are several factors to consider. Firstly, in terms of durability and strength, stainless steel pipes have a clear advantage. Stainless steel is known for its high tensile strength and resistance to corrosion, making it suitable for a wide range of applications. On the other hand, while HDPE pipes are also durable, they may not be as strong as stainless steel and may require additional support in certain situations. Secondly, when it comes to temperature resistance, stainless steel pipes again have an edge. They can withstand high temperatures without losing their structural integrity, making them suitable for applications involving hot fluids or gases. HDPE pipes, on the other hand, may soften or deform at elevated temperatures, limiting their use in high-temperature environments. Another aspect to consider is the ease of installation. HDPE pipes are typically lighter and more flexible than stainless steel pipes, making them easier to transport and install. They also require fewer fittings and joints, reducing the chances of leaks. However, stainless steel pipes can be more rigid and may require additional welding or threading during installation. Cost is another factor to consider. HDPE pipes are generally more cost-effective than stainless steel pipes, especially for larger diameter pipes. This affordability, coupled with the ease of installation, makes HDPE pipes a popular choice in many applications. However, it is important to note that stainless steel pipes have a longer lifespan and require less maintenance, potentially offsetting the initial cost difference over time. Ultimately, the choice between stainless steel pipes and HDPE pipes depends on the specific requirements of the application. While stainless steel pipes offer superior strength, temperature resistance, and longevity, HDPE pipes are lighter, more flexible, and more cost-effective. Assessing the needs of the project and considering these factors will help determine the most suitable option.

- Q: How do you calculate the heat transfer coefficient of stainless steel pipes?

- The heat transfer coefficient of stainless steel pipes can be calculated using empirical correlations or experimental measurements. Empirical correlations involve using equations that relate the heat transfer coefficient to parameters such as the flow rate, pipe diameter, and fluid properties. These correlations are often based on extensive experimental data and can provide reasonably accurate estimates. Alternatively, experimental measurements involve directly measuring the temperature difference across the pipe wall and the heat flux. By dividing the heat flux by the temperature difference, the heat transfer coefficient can be obtained. However, experimental measurements can be more time-consuming and may require specialized equipment.

- Q: 316 stainless steel pipe wall mirror polishing, the smaller the roughness, the better.

- Steel pipe is purchased separately, and then polished to find manufacturers alone, can meet the requirements,The cost is very high. To tell you the truth, I don't know.Specializing in sanitary stainless steel tube, stainless steel tube, precision sanitary stainless steel tube and stainless steel tube precision tube production and sales, the main material: stainless steel material: 0Cr18Ni9 (304 stainless steel tube) and 00Cr19Ni10 (304L stainless steel tube (316), stainless steel tube), 00Cr17Ni14Mo2 (GB 316L stainless steel tube), the products are widely used in instrumentation pharmaceutical machinery, food machinery, auto parts, pneumatic components, beverage, beer, drinking water, air purification and biological engineering and other fields.

- Q: Are stainless steel pipes resistant to pitting and crevice corrosion?

- Yes, stainless steel pipes are generally resistant to pitting and crevice corrosion due to their high chromium content, which forms a protective oxide layer on the surface, preventing corrosion. However, the resistance can vary depending on the specific grade of stainless steel and the environment in which the pipes are used.

- Q: 304 stainless steel seamless tube weight how to calculate?

- The common marking methods in the market are 00Cr19Ni10, SUS304, in which 00Cr19Ni10 is generally used to indicate standard production of the national standard. Generally speaking, ASTM standard production is indicated, and SUS 304 represents standard production.

Send your message to us

American Standard ASTM A240 304 Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords