Lennox Lh49 62e9t Aluminum Coil Price - Aluminum Sheets Stucco Embossed AA1060 H24 from China Famous Company

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Thickness | 0.1mm-8mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm |

Width | 20mm-2500mm |

inner diameter | 76mm / 152mm |

Material | AA1050, AA1060, AA1070, AA1100, AA1235, AA3003, AA3004, AA3005, AA5052, AA5005, AA5754, AA5083, AA8011, AA8079, etc |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38, |

Surface | Mill finish / Coated |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 30-35 days after the receiving L/C or deposit |

2. Application of

(1) Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors, windows,

(2) Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations.

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

4. Certificate:

SGS and ROHS (if clients request, paid by client), MTC (plant provided), Certificate of Origin (FORM A, FORM E, CO), Bureau Veritas (if client request, paid by client), CIQS certificate and so on.

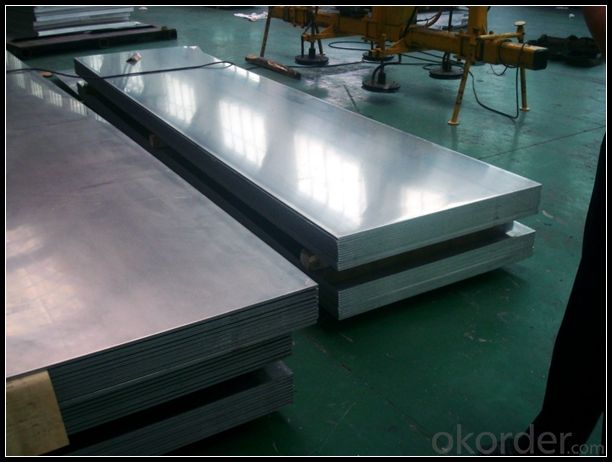

5. Image of Aluminum sheets

6. Package and shipping of

Eye to wall

Eye to the wall

With wooden pallet (wooden case also available)

7. FAQ

1) What is the delivery time?

Depends on actual order, around 30 to 35 days

2) What is the QC system?

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: im doing this essay in my chemistry class that suppose to be a ficional story about the day my element, aluminum, slowly began disappearing.i know some things that will happen like no soda cans of anything of that, no foil no forks or spoons anything metally. i need more effects that will happen but my major problem is how to start this. i have no clue like how to begin.can anyone help pleased.!

- Mass produced things like aluminum don't just disappear in one day. They would already use alternative resource by the time it was scarce.

- Q: How are aluminum coils formed into different shapes and profiles?

- Metal forming is the process by which aluminum coils are transformed into various shapes and profiles. This involves applying force to the coil to alter its shape and contour. There are multiple techniques employed for shaping aluminum coils, including rolling, bending, extrusion, and stamping. The most commonly used method for shaping aluminum coils is rolling. This entails passing the coil through a series of rollers that gradually change its shape by applying pressure. The rolling process can be carried out either hot or cold, depending on the desired outcome. Hot rolling is typically used for thicker coils, while cold rolling is suitable for thinner ones. Bending is another technique employed to shape aluminum coils, particularly when creating curved or angled profiles. This can be done manually or with the assistance of specialized bending machines. By exerting force, the coil is bent to the desired shape, creating curves or angles as required. Bending is widely utilized in applications such as HVAC systems, automotive components, and construction. Extrusion is a process in which the aluminum coil is forced through a die to achieve a specific cross-sectional shape. The coil is heated and pushed through the die, which determines the final shape of the extrusion. This method is frequently employed to create intricate profiles with consistent dimensions, such as window frames, door frames, and structural components. Stamping is a technique utilized to produce precise shapes and patterns on the surface of aluminum coils. It involves pressing the coil against a die with the desired design, causing the metal to deform and adopt the shape of the die. Stamping is commonly employed for decorative purposes, such as creating patterns, logos, or text on aluminum sheets. In conclusion, various metal forming methods, namely rolling, bending, extrusion, and stamping, enable aluminum coils to be transformed into diverse shapes and profiles. These processes facilitate the customization and versatility of aluminum in numerous industries and applications.

- Q: Are there any recycling programs for used aluminum coils?

- Indeed, recycling programs for used aluminum coils are readily accessible. Aluminum, being highly recyclable, can be melted down and repurposed without compromising its quality. Numerous recycling centers and scrap metal yards willingly accept aluminum coils for recycling purposes. Furthermore, certain HVAC companies, which frequently employ aluminum coils in air conditioning systems, have implemented their own recycling initiatives. It is advisable to consult your local recycling center or HVAC companies to obtain information regarding the specific recycling programs available for used aluminum coils in your vicinity.

- Q: How do aluminum coils contribute to energy-efficient insulation?

- Aluminum coils contribute to energy-efficient insulation by serving as a barrier that prevents the transfer of heat. Due to aluminum's excellent thermal conductivity, it efficiently conducts and dissipates heat, reducing energy loss and improving insulation performance. Additionally, aluminum coils can be used in the construction of air conditioning and refrigeration systems, where they enhance energy efficiency by enabling better heat transfer and reducing energy consumption.

- Q: where's the best place to look for aluminum not cans

- It depends on what you will use it for. If you are just looking for scrap aluminum to be melted down, cars radiators a full of aluminum. Otherwise, maybe check with a local metal fabricator and see if you could buy some of their drop.

- Q: Can aluminum coils be used for gutter systems?

- Yes, aluminum coils can be used for gutter systems. Aluminum is a popular material for gutters due to its lightweight nature, durability, and resistance to rust and corrosion. Aluminum coils are often used to form seamless gutters, which offer advantages such as fewer leaks and a more aesthetically pleasing appearance. Additionally, aluminum gutters are easy to maintain and can be painted to match the exterior of a building. Overall, aluminum coils are a suitable and commonly used choice for gutter systems.

- Q: Can aluminum coils be utilized in the process of welding?

- <p>Yes, aluminum coils can be used for welding work. They are commonly used as filler material in processes like MIG (Metal Inert Gas) welding. Aluminum welding requires specific techniques and equipment due to its high thermal conductivity and the need for shielding from oxidation. The aluminum coils must be of good quality and compatible with the welding process to ensure a strong and durable weld. Proper selection of welding parameters, such as amperage and voltage, is crucial for successful aluminum welding.</p>

- Q: Are aluminum coils resistant to saltwater corrosion?

- Yes, aluminum coils are resistant to saltwater corrosion.

- Q: Can aluminum coils be customized?

- Indeed, it is possible to customize aluminum coils to meet specific requirements. These coils possess remarkable versatility, as they can be tailored in terms of thickness, width, length, alloy composition, surface finish, and other specifications. Consequently, they find extensive utility across diverse industries, including construction, automotive, aerospace, electronics, and packaging. The customization of aluminum coils involves various processes, such as slitting, cutting-to-length, embossing, painting, and coating. This remarkable flexibility in customization empowers manufacturers to satisfy the distinct demands of their clientele, thereby ensuring that the aluminum coils are perfectly optimized for their intended applications.

- Q: How can you tell the difference between aluminum and other non-magnetic metals, such as what I've heard called, pot-metal?

- Aluminum is very light. Pot metal, also known as white metal, die-cast zinc, or monkey metal,[1] is a slang term that refers to alloys that consist of inexpensive, low-melting point metals used to make fast, inexpensive castings. There is no scientific metallurgical standard for pot metal; common metals in pot metal include zinc, lead, copper, tin, magnesium, aluminium, iron, and cadmium. The primary advantage of pot metal is that it is quick and easy to cast. Due to its low melting temperature no sophisticated foundry equipment is needed and specialized molds are not necessary. It is sometimes used to experiment with molds and ideas before using metals of higher quality. Examples of items created from pot metal include toys, furniture fittings, tool parts, electronics components, and automotive parts.[citation needed] Pot metal can be prone to instability over time, as it has a tendency to bend, distort, crack, shatter, and pit with age.[1] The low boiling point of zinc and the fast cooling of the newly-cast part often allow air bubbles to remain within the cast part, weakening the metal.[1] Many of the components of pot metal are susceptible to corrosion from airborne acids and other contaminants, and the internal corrosion of the metal often causes the decorative plating to flake off.[citation needed] Pot metal is not easily glued, soldered or welded.[1] At one time, pot metal referred to a copper alloy that was primarily alloyed with lead. 67% Cu, 29% Pb 4% Sb and 80% Cu, 20% Pb were common formulations.[2] The primary component of pot metal is zinc, but often the caster adds other metals to the mix to strengthen the cast part, improve the flow of the molten metal, or to reduce cost.[dubious – discuss] With a low melting point of 419 °C (786 °F), zinc is often alloyed with other metals including lead, tin, aluminium and copper.

Send your message to us

Lennox Lh49 62e9t Aluminum Coil Price - Aluminum Sheets Stucco Embossed AA1060 H24 from China Famous Company

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords