Aluminum Sheets for Racing:Best Price Aluminium Plate and Sheet in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series,7000series,8000 series,etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,H112,O, H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

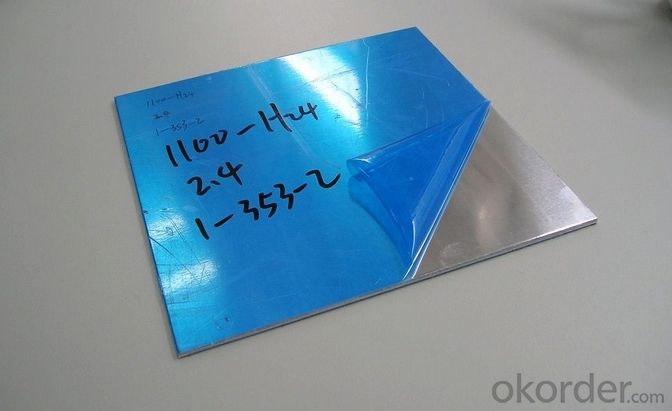

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm, 1250mm*2500mm, at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year

Japan, Vietnam, Singapore,Turkey,Fiji, etc.

What is your mainly products?

---Normally they are aluminum sheet,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What is the weight of the aluminum sheets?

- The weight of the aluminum sheets will depend on their size and thickness.

- Q: Can aluminum sheets be coated with other materials?

- Yes, aluminum sheets can be coated with other materials. This process is known as aluminum sheet coating or aluminum sheet finishing. Coating aluminum sheets with other materials serves multiple purposes, such as enhancing their appearance, protecting against corrosion, improving durability, and providing insulation. There are various methods to coat aluminum sheets, including painting, anodizing, laminating, and powder coating. Each method offers different benefits and is chosen based on the desired outcome and intended use of the coated aluminum sheet. Coating aluminum sheets with other materials allows for customization, versatility, and increased functionality in a wide range of applications, including construction, automotive, aerospace, and consumer goods industries.

- Q: What is an aluminum sheet?

- An aluminum sheet refers to a flat, thin piece of aluminum that is usually rectangular in shape. It is commonly used in various industries and applications due to its lightweight, durability, and corrosion resistance properties. Aluminum sheets can be easily manipulated, cut, and formed into different shapes to meet specific requirements in construction, automotive, aerospace, and manufacturing sectors.

- Q: How does the thickness tolerance of aluminum sheet affect its usability?

- The thickness tolerance of aluminum sheet plays a significant role in its usability. A narrow thickness tolerance ensures uniformity and precision in the sheet's dimensions, allowing for consistent performance and ease of fabrication. It enables seamless integration into various applications, including construction, automotive, aerospace, and manufacturing industries. On the other hand, a wider thickness tolerance can limit its usability as it may result in irregularities, difficulty in fitting, and potential performance issues. Therefore, a tight thickness tolerance is crucial for ensuring optimal functionality and versatility of aluminum sheets.

- Q: What are the standard tolerances for aluminum sheets?

- The standard tolerances for aluminum sheets can vary depending on the specific application and industry requirements. However, common tolerances for thickness range from +/- 0.005 to +/- 0.015 inches, while dimensions may have tolerances in the range of +/- 0.030 to +/- 0.125 inches. It is important to consult the appropriate industry standards or specifications for precise tolerances based on the specific needs of the project.

- Q: Can aluminum sheets be used for reflective surfaces?

- Yes, aluminum sheets can be used as reflective surfaces due to their high reflectivity and low emissivity properties.

- Q: How does the purity of aluminum affect its properties as a sheet?

- The properties of aluminum as a sheet are significantly influenced by its purity. Increased levels of purity generally lead to improved mechanical properties, as well as enhanced thermal and electrical conductivity, and better resistance against corrosion. When aluminum possesses a high level of purity, meaning it contains minimal impurities, it becomes more malleable and ductile. This characteristic makes it easier to shape into thin sheets, rendering highly pure aluminum sheets more appropriate for applications requiring intricate shapes and designs. Moreover, the high electrical conductivity of pure aluminum makes it an exceptional choice for electrical applications, such as wiring and circuit boards. It enables efficient transmission of electricity while minimizing the risk of overheating. Additionally, the thermal conductivity of pure aluminum makes it an ideal option for heat transfer purposes. Aluminum sheets with a high level of purity can effectively dissipate heat, making them well-suited for applications like heat sinks and radiators. Furthermore, the corrosion resistance of aluminum increases with higher levels of purity. Pure aluminum forms a protective oxide layer on its surface, which serves to prevent corrosion and prolong the lifespan of aluminum sheets in various environments. In conclusion, the purity of aluminum directly impacts its properties as a sheet. Increased levels of purity enhance its mechanical properties, as well as its electrical and thermal conductivity. Additionally, it improves its resistance against corrosion, making it more versatile and suitable for a wide range of applications.

- Q: Do the aluminum sheets come with a protective coating?

- Indeed, the aluminum sheets are accompanied by a protective coating, which is skillfully applied in order to safeguard against any potential scratches, corrosion, or other forms of damage that may occur during the process of transportation and handling. This meticulous coating process guarantees that the aluminum sheets are delivered to our cherished customers in an immaculate state.

- Q: This question asks for a comparison of the positive and negative aspects of utilizing aluminum sheets in building construction.

- <p>Aluminum sheets in construction offer several advantages, including lightweight properties that reduce structural load, excellent corrosion resistance, and durability which minimizes maintenance needs. They are also energy-efficient, reflecting heat and reducing cooling costs. Additionally, aluminum is recyclable, contributing to sustainability. Disadvantages include higher initial costs compared to some traditional materials and potential for dents or damage from impacts. Aluminum can also be noisy when walked on, and it may require additional insulation for thermal performance, adding to the overall cost.</p>

- Q: What are the advantages of using aluminum sheets?

- Some advantages of using aluminum sheets include their lightweight nature, corrosion resistance, and high strength-to-weight ratio. Aluminum sheets are also highly malleable, making them easy to form into various shapes and sizes. Additionally, aluminum is a highly recyclable material, making it more environmentally friendly compared to other metals.

Send your message to us

Aluminum Sheets for Racing:Best Price Aluminium Plate and Sheet in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords