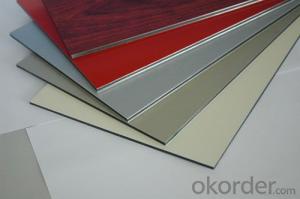

Colored Aluminum Sheets for Campers - Versatile Aluminum Sheet/Coil and Foil Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum sheet coil and foil for versatile application

1).Alloy:1050 1060 1070 1100 3003 3004 3005 5052 5083 5754 8011

2).Temper:O H14 H16 H18 H24 H26 H32 H111

3).Thickness:0.2-8mm

4).Width:50-1900mm

5).Application:Construction, decoration, pipe, packaging, automobile, air conditioning, pot containers, refrigeration, electrical and electronic products, etc.

At present, we can supply 1xxx 3xxx 5xxx 8xxx series aluminum alloy sheet/ plate/ coil/ foil in various specification. With good quality and competitive price, we will furnish you the best product and serive.

Aluminum sheet

| Allloy | Specifications(mm) | Temper | Standard | Application | |

| Thickness | Width | ||||

1070,1060,1145, 1050,1100,1235 | 0.2-6.0 | 900-1900 | O,H12,H22,H14, H24,H16,H26,H18 | GB/T3190-1996 GB/T3880-1997 | Construction,decoration, pipe,packaging,automobile, air conditioning,pot containers,refrigeration, electrical and electrical products,etc. |

| 3A21,3003,3004 | 0.2-6.0 | 900-1900 | O,H14,H24,H18 | GB/T3190-1996 GB/T3880-1997 GB/T3194-1997 | |

| 5052,5A02,5005 | 0.2-6.0 | 900-1900 | O,H12,H22,H32, H14,H24,H34,H16, H26,H36,H18,H38 | GB/T3190-1996 GB/T3880-1997 | |

| 8011 | 0.2-6.0 | 900-1900 | O,H14,H24,H18 | GB/T3190-1996 GB/T3880-1997 | |

Aluminum coils

| Allloy | Specifications(mm) | Temper | Standard | Application | |

| Thickness | Width | ||||

1070,1060,1145, 1050,1100,1235 | 0.2-12 | 25-1900 | O,H12,H22,H14, H24,H16,H26,H18 | GB/T3190-1996 GB/T3880-1997 | Construction,decoration, pipe,packaging,automobile, air conditioning,pot containers,refrigeration, electrical and electrical products,etc. |

| 3A21,3003,3004 | 0.2-12 | 25-1900 | O,H14,H24,H16, H26,H18 | GB/T3190-1996 GB/T3880-1997 GB/T3194-1997 | |

5052,5005, 5754,5083 | 0.2-12 | 25-1900 | O,H12,H22,H32,H14, H24,H34,H16,H26, H36,H18,H38 | GB/T3190-1996 GB/T3880-1997 | |

| 8011 | 0.2-12 | 25-1900 | O,H14,H24,H16, H26,H18 | GB/T3190-1996 GB/T3880-1997 | |

Aluminum foil

| Alloy | Specifications(mm) | Temper | Standard | Application | |

| Thickness | Width | ||||

1100,1200,1050 1060,1070 | 0.0065-0.200 | 15-1200 | O,H22,H14,H24 H16,H26,H18, H19 | GB/T3190-1996 GB/T3198-2003 YS/T430-2000 YS/T95.1-2001 | Air-conditioning,cable, cigarettes,food,medicine, decoration,capacitor, beer,drinks,etc |

| 3003,3004,3005 | 0.012-0.200 | 15-1200 | O,H14,H24,H16 H26,H18 | GB/T3190-1996 GB/T3198-2003 | |

5052 5005 5754 5083 | 0.012-0.200 | 15-1200 | O,H14,H24,H16 H26,H18 | GB/T3190-1996 GB/T3198-2003 | |

| 8011 | 0.0065-0.200 | 15-1200 | O,H22,H14,H24 H16,H26,H18 H19 | GB/T3190-1996 GB/T3198-2003 | |

- Q: What is the difference between aluminum sheet and aluminum curtain wall? The cost is high!

- Composite aluminum plate is also called aluminum plastic plate, which is composed of aluminum plastic aluminum three layers, aluminum single board is made of whole aluminum, and aluminum single board is fabricated more than aluminum plastic plate

- Q: Can aluminum sheets be used for electrical connectors?

- Yes, aluminum sheets can be used for electrical connectors.

- Q: What are the special coatings or treatments available for enhancing the properties of aluminum sheets?

- <p>Yes, there are several special coatings and treatments that can be applied to aluminum sheets to enhance their properties. These include anodizing, which creates a protective oxide layer, powder coating for a durable and colorful finish, and thermal spraying for improved wear resistance. Other treatments involve chemical conversion coatings, such as chromate conversion, which provides corrosion resistance, and various types of plating like electroplating or hot-dip galvanizing for added strength and protection. These treatments can significantly improve the appearance, durability, and performance of aluminum sheets in various applications.</p>

- Q: Can aluminum sheets be anodized for aesthetic purposes?

- Yes, aluminum sheets can be anodized for aesthetic purposes. Anodizing is a process that creates a protective oxide layer on the surface of aluminum, which can be further enhanced with various colors and finishes for aesthetic appeal.

- Q: Inquire whether aluminum sheets are generally more costly compared to other sheet metal materials.

- <p>Aluminum sheets are not necessarily more expensive than other types of sheet metal. The cost can vary based on factors such as the current market price of the metal, the thickness and grade of the sheet, and the specific alloy used. Generally, aluminum is less expensive than metals like stainless steel or copper, but it can be more expensive than common metals like steel or iron. Prices fluctuate, so it's best to check current market prices for the most accurate comparison.</p>

- Q: What specific criteria or conditions must be met when utilizing high-quality aluminum sheets in construction?

- <p>High-quality aluminum sheets used in construction projects require adherence to specific standards. They must possess high strength, corrosion resistance, and durability to withstand environmental conditions. Compliance with industry standards such as ASTM or ISO is crucial. Additionally, the sheets should be compatible with other construction materials and meet safety regulations. Proper installation techniques and qualified personnel are also essential to ensure the integrity and longevity of the construction project.</p>

- Q: Can the aluminum sheets be used for manufacturing heat exchanger fins?

- Yes, aluminum sheets can be used for manufacturing heat exchanger fins. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity and corrosion resistance. The lightweight and malleable nature of aluminum sheets make them ideal for forming fins with high surface area to enhance heat transfer. Additionally, aluminum is readily available and cost-effective, making it a popular choice in heat exchanger manufacturing.

- Q: What are the different methods for finishing the edges of aluminum sheets?

- Depending on the desired outcome and application, there are several approaches to finishing the edges of aluminum sheets. One commonly used method is edge trimming, where excess material is removed from the sheet's edges to achieve a smooth and straight edge. This can be accomplished using various tools like shears, saws, or routers. Another technique is edge deburring, which is employed to eliminate any sharp or rough edges left after cutting. Sanding or grinding tools are often utilized to smooth out the edges and produce a more polished finish. Moreover, edge rolling is a method that can be employed to create rolled or rounded edges on aluminum sheets. This is achieved by using a rolling machine that applies pressure to the edges, bending them into the desired shape. For a more decorative finish, edge profiling can be employed. This involves using specialized tools or machines to craft custom edge shapes or designs on the aluminum sheet. It allows for unique and aesthetically pleasing edges that enhance the overall appearance of the sheet. Lastly, edge painting or coating is an option worth considering. This process entails applying a protective or decorative paint or coating to the edges of the aluminum sheet. This not only provides a finished look but also helps protect the edges from corrosion or other damage. Ultimately, the choice of method for finishing the edges of aluminum sheets depends on factors such as the intended use, desired appearance, and specific project requirements.

- Q: This question asks for a comparison between the benefits and drawbacks of utilizing products made from recycled aluminum.

- <p>Advantages of using recycled aluminum products include reduced energy consumption, lower greenhouse gas emissions, and a decrease in the need for raw material extraction. It also promotes waste reduction and supports a circular economy. Disadvantages might include potential quality concerns, as recycled aluminum might not always meet the same strength and durability standards as new aluminum. Additionally, there can be higher initial costs associated with recycling processes and the need for advanced sorting and processing technologies.</p>

- Q: Are aluminum sheets suitable for HVAC systems?

- Yes, aluminum sheets are suitable for HVAC systems. Aluminum is a lightweight and durable material that provides excellent thermal conductivity, making it ideal for use in HVAC systems. It is commonly used for making ductwork, heat exchangers, and fins in air conditioning units. Aluminum sheets are corrosion-resistant, which is advantageous in environments with high humidity or exposure to moisture. Additionally, aluminum is a recyclable material, making it an environmentally friendly choice for HVAC systems. Overall, aluminum sheets offer numerous benefits and are widely used in the HVAC industry.

Send your message to us

Colored Aluminum Sheets for Campers - Versatile Aluminum Sheet/Coil and Foil Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords