Aluminum Sheets & Plates for Metal Ceiling System - Aluminum Rolls Cost

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Rolls Cost for Metal Ceiling System

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Rolls Cost for Metal Ceiling System

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

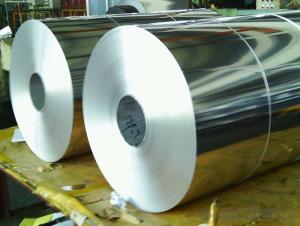

3. Aluminum Rolls Cost for Metal Ceiling System Images

4.Specification of Aluminum Rolls Cost for Metal Ceiling System

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: I have been doing this science prac at school and I have received some strange results. I measured the density of this metal, which leads me to believe it is Aluminium. Also, its silvery appearance supports this. When I have attempted to react it with Hydrochloric Acid, Sulfuric Acid and the nitrates/chlorides of a few metals, I have received some odd results.Despite having a high reactivity, the only substance it has reacted with so far out of all of the above is Tin Chloride. Am I doing something wrong? Is it possible that it isn't aluminium and rather a similar metal such as zinc? Thanks in advance :)

- Aluminum is very reactive so what happens is that it has a coat aluminum oxide as soon as it comes in contact with oxygen the outer layer forms aluminum oxide Al2O3. That is why Aluminum does not rust. The Al203 coat protects it.

- Q: How do aluminum plates paint?

- Pretreatment is usually required. Acid and alkali cleaning can be done either by oil or by xylene,The paintings do not know, but most of them are painted or printed on the aluminum plate, usually by heat transfer, silk screen, or decorative board, which is sprayed directly and then painted.

- Q: Is it possible to utilize recycled aluminum scraps as an alternative to purchasing new aluminum sheets for a project?

- <p>Yes, you can use recycled aluminum scraps in your project instead of buying new aluminum sheets. Recycled aluminum is not only environmentally friendly but also cost-effective. It has similar properties to new aluminum, making it suitable for many applications. However, ensure the quality and purity of the recycled aluminum meet your project's requirements. Check for any impurities or inconsistencies that might affect the strength or performance of your final product. If the recycled aluminum is in good condition and appropriate for your needs, it can be a sustainable and economical choice.</p>

- Q: I can't seem to find what uses or contains Aluminum Nitride. Help!

- Don't know where you looked, but this came up with very basic web search. Metallization methods are available to allow Aluminium nitride to be used in electronics applications similar to those of alumina and beryllium oxide. Among the applications of Aluminium nitride are opto-electronics, dielectric layers in optical storage media, electronic substrates, chip carriers where high thermal conductivity is essential, military applications, as a crucible to grow crystals of gallium arsenide, steel and semiconductor manufacturing. Epitaxially grown thin film crystalline aluminium nitride is also used for surface acoustic wave sensors (SAW's) deposited on silicon wafers because of the Aluminium nitride's piezoelectric properties. One application is an RF filter used in mobile phones called a thin film bulk acoustic resonator (FBAR). This is a MEMS device that uses aluminium nitride sandwiched between two metal layers.

- Q: Can the aluminum sheets be used for manufacturing aircraft engine components?

- Indeed, the utilization of aluminum sheets is possible for the production of aircraft engine components. Due to its exceptional strength-to-weight ratio and resistance to corrosion, aluminum is extensively employed within the aerospace sector. Despite being lightweight, it possesses the necessary strength to endure the strains and elevated temperatures inherent in aircraft engines. Furthermore, aluminum sheets can be effortlessly fashioned, rendering them apt for the creation of intricate engine components. Taken together, the favorable mechanical properties and applicability to aerospace scenarios make aluminum sheets the preferred option for manufacturing aircraft engine components.

- Q: What is the maximum width available for aluminum sheets?

- The maximum width available for aluminum sheets can vary depending on the manufacturer and specific requirements. However, in general, aluminum sheets are commonly available in widths up to 72 inches or 1.83 meters. It is important to note that some manufacturers may offer even wider options for specialized applications. Additionally, custom sizes can also be obtained through specific orders, allowing for greater flexibility in width choices.

- Q: heating can affect aluminium

- This is science so, if you want specific answers, you must ask specific questions. What type of aluminum are you interested in? What characteristics are important to you? What kind of factors are you talking about? You are right that heating can affect Al. In fact, heating affects, basically, everything, every material we know of and every physical and chemical process that we do and every process that happens in nature. Temperature is important in all of these. There are more than a hundred different commercial aluminum alloys and most of them are available in a variety of different tempers (heat treated conditions). The heat treatment of commercial Al alloys is a very important thing. If you want more specific information, consult your friendly neighborhood metallurgist.

- Q: Can the aluminum sheets be used in marine environments?

- Indeed, aluminum sheets are suitable for deployment in marine settings. Owing to its exceptional resistance to corrosion, aluminum stands as a favored selection for marine utilization. Unlike its counterparts, aluminum develops a safeguarding oxide layer when it comes into contact with oxygen, thereby inhibiting further corrosion. Consequently, it proves to be the perfect choice for employment in environments saturated with saltwater, where the probabilities of rusting and corrosion are notably elevated. Moreover, aluminum boasts attributes such as its lightweight nature, durability, and an outstanding strength-to-weight ratio, rendering it a fitting option for an array of marine applications, encompassing boat hulls, ship construction, offshore platforms, and an array of other marine structures.

- Q: Can the aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its lightweight nature, durability, and versatility. It can be easily molded and shaped into various forms, making it suitable for a wide range of architectural designs. Additionally, aluminum is resistant to corrosion, making it a long-lasting option for cladding. Its ability to be coated in different finishes also allows for customization to match the desired aesthetic of the building. Overall, aluminum sheets are a reliable and practical choice for architectural cladding.

- Q: How much do aluminum sheets typically weigh?

- The weight of aluminum sheets ranges from 1.9 to 3.4 grams per square centimeter, and this varies depending on the sheet's thickness and size. Aluminum sheet weight can differ considerably based on its dimensions and gauge. Thinner sheets are typically lighter, while thicker ones tend to be heavier. It is worth mentioning that factors like the alloy utilized and any surface coatings or treatments can also impact the weight of aluminum sheets. Hence, it is recommended to refer to the product specifications or contact the manufacturer for precise weight details.

Send your message to us

Aluminum Sheets & Plates for Metal Ceiling System - Aluminum Rolls Cost

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords