Aluminum Profiles for Solar Panel Frame - Aluminium Profile Extrusion 6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: Are aluminum profiles suitable for swimming pool enclosures?

- Yes, aluminum profiles are indeed suitable for swimming pool enclosures. Aluminum is a highly durable and lightweight material that is resistant to rust and corrosion, making it ideal for use in humid and moist environments such as swimming pools. It is also highly versatile and can be easily customized to fit any pool size or shape. Additionally, aluminum profiles provide excellent structural strength, ensuring the stability and longevity of the enclosure. Furthermore, aluminum is a low-maintenance material that requires minimal upkeep, making it a cost-effective choice for pool enclosures. Overall, the use of aluminum profiles in swimming pool enclosures offers numerous benefits, including durability, versatility, and low maintenance, making it an excellent choice for protecting and enhancing the swimming pool area.

- Q: Can aluminum profiles be used for greenhouse construction?

- Indeed, greenhouse construction can make use of aluminum profiles. The durability, lightweight characteristics, and corrosion resistance of aluminum make it a favored selection for greenhouse frames. Moreover, aluminum proves to be easily manageable, enabling flexibility in design and construction. The utilization of aluminum profiles yields a robust and steady structure capable of enduring severe weather conditions and providing enduring support for greenhouse coverings. Furthermore, aluminum frames necessitate minimal upkeep and possess a lengthier lifespan in comparison to alternative materials, rendering them a cost-efficient choice for greenhouse construction.

- Q: This question asks for an overview of the various types of aluminum profiles that are typically utilized in construction projects.

- <p>Aluminum profiles used in construction come in various types, each serving specific purposes. Common types include: 1. Extruded Profiles: These are the most common, created by forcing aluminum through a die to achieve desired shapes. 2. Structural Profiles: Used for structural integrity in buildings, such as beams and columns. 3. Fa莽ade Profiles: Specifically designed for the exterior cladding of buildings. 4. Window and Door Profiles: For frame construction in windows and doors. 5. Fastening Profiles: Used for joining and fixing other aluminum components. 6. Special Profiles: Custom-made for unique applications. 7. Decorative Profiles: For aesthetic purposes, enhancing the appearance of structures. Each type has specific properties and is chosen based on the structural requirements and design considerations of the construction project.</p>

- Q: What are the advantages of utilizing recycled aluminum in construction projects in terms of environmental impact?

- <p>Using recycled aluminum profiles in construction offers significant environmental benefits. It conserves natural resources by reducing the need for mining bauxite, which is the primary source of aluminum. This reduction in mining decreases habitat destruction and soil erosion. Additionally, recycling aluminum requires significantly less energy compared to producing it from raw materials, which cuts down on greenhouse gas emissions and reduces the overall carbon footprint. Furthermore, the use of recycled aluminum helps in waste management by diverting materials from landfills, thereby reducing pollution and the environmental burden of waste disposal.</p>

- Q: Can aluminum profiles be used for display systems?

- Yes, aluminum profiles can definitely be used for display systems. Aluminum is a popular choice for display systems due to its lightweight yet strong nature. It is highly versatile and can be easily customized to fit the specific requirements of the display system. Aluminum profiles can be used to create frames, shelves, stands, and other components of the display system. They are also corrosion-resistant, making them suitable for both indoor and outdoor display applications. Additionally, aluminum profiles offer a sleek and modern aesthetic, giving the display system an attractive appearance. Overall, aluminum profiles are a reliable and efficient choice for designing and constructing display systems.

- Q: Are aluminum profiles suitable for use in the renewable energy industry?

- Yes, aluminum profiles are suitable for use in the renewable energy industry. Aluminum is a versatile and lightweight material that offers several advantages for renewable energy applications. Firstly, aluminum profiles have excellent corrosion resistance, making them suitable for use in outdoor environments where they may be exposed to moisture or harsh weather conditions. This durability ensures that the profiles can withstand the test of time and maintain their structural integrity. Furthermore, aluminum profiles are highly recyclable, making them an environmentally friendly choice for the renewable energy industry. As the industry strives to reduce its carbon footprint and promote sustainability, the recyclability of aluminum helps in achieving these goals. Aluminum can be recycled repeatedly without losing its essential properties, which reduces the need for extracting and processing new raw materials. Aluminum profiles also offer design flexibility, allowing for the creation of complex shapes and structures that can be customized to meet specific requirements. This versatility makes them suitable for various renewable energy applications, such as solar panel frames, wind turbine components, and mounting systems. Additionally, the lightweight nature of aluminum profiles simplifies transportation and installation processes, reducing costs and energy consumption. In summary, aluminum profiles are an excellent choice for the renewable energy industry due to their corrosion resistance, recyclability, design flexibility, and lightweight properties. These attributes contribute to the overall efficiency, durability, and sustainability of renewable energy systems, making aluminum profiles a suitable material for use in this industry.

- Q: How do aluminum profiles perform in terms of sound insulation?

- Compared to materials like wood or uPVC, aluminum profiles generally do not have good sound insulation properties. This is because aluminum is lightweight and thin, allowing sound waves to easily pass through. Furthermore, aluminum profiles often have a hollow structure, which further reduces their ability to block or absorb sound. It is important to consider that the overall sound insulation performance of a window or door system depends on various factors. These include the thickness of the glass, the quality of the seals, and the installation method. To improve the sound insulation capabilities of aluminum profiles, manufacturers may incorporate additional features such as double or triple glazing, laminated glass, or acoustic seals. In conclusion, while aluminum profiles alone may not offer optimal sound insulation, their performance can be enhanced by combining them with other elements. If sound insulation is a major concern, it is advisable to explore alternative materials that inherently provide better sound insulation properties.

- Q: What is the relationship between aluminum alloy and aluminum alloy?

- Two, according to the alloy can be divided into 1024 categories: a 2011, 6063, 6061, 6082, 7075 grade aluminum alloy, which is the 6 most common. Grades are different in various metal components ratio is not the same, in addition to the commonly used aluminum doors and windows In addition to such as the 60 series, 70 series, 80 series, 90 series, curtain wall series aluminum profile, aluminum industry has no clear distinction model, most manufacturers are in accordance with the actual drawings processing customer. Three, according to the requirement of surface treatment: 1. anodized aluminum 2. Electrocoat aluminum 3. aluminum powder coating 4. transfer grain aluminum 5. aluminum polishing (divided into mechanical polishing and chemical polishing of two, the chemical polishing of the highest cost, the price is the most expensive)

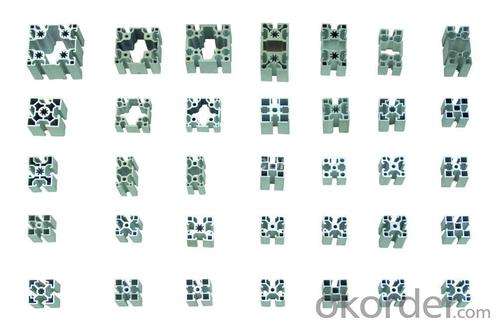

- Q: What are the different cross-sectional shapes available for aluminum profiles?

- Aluminum profiles come in various cross-sectional shapes, each with its own distinct characteristics and uses. Some commonly encountered shapes are: 1. Square profiles: These have equal sides and 90-degree corners, making them suitable for applications that require strength and stability, such as frames and supports. 2. Rectangular profiles: With unequal sides and 90-degree corners, these profiles offer a larger surface area and increased strength, making them popular in construction and transportation industries. 3. Round profiles: These profiles have a circular cross-section and are favored for their smooth appearance and excellent strength-to-weight ratio. They are commonly found in furniture, automotive parts, and lighting fixtures. 4. T-slot profiles: These profiles feature a T-shaped groove on one or more sides, allowing for easy assembly of components using specialized fasteners. They are widely used in machine frames, workstations, and robotics. 5. L-shaped profiles: These profiles have two perpendicular sides forming a 90-degree angle, making them ideal for corner joints, braces, and edges. They provide structural support and stability in various applications. 6. U-shaped profiles: These profiles have a concave shape resembling the letter "U" and are often used for trim, edging, and protective barriers. They provide a neat and finished look. 7. Custom shapes: In addition to the standard shapes mentioned above, aluminum profiles can also be customized to meet specific design requirements. This flexibility allows for the creation of unique profiles tailored to specific applications or industries. In summary, the availability of different cross-sectional shapes for aluminum profiles gives designers and engineers a wide range of options. This ensures compatibility with various applications and enables efficient and effective use of this versatile material.

- Q: This question asks about the impact of aluminum profiles on the longevity and strength of a building structure.

- <p>Aluminum profiles significantly enhance the durability of a building due to their high strength-to-weight ratio, excellent resistance to corrosion, and low maintenance requirements. They are lightweight yet strong, making them ideal for load-bearing structures and facades. Corrosion resistance means they withstand harsh weather conditions without rusting, which is common in steel profiles. This durability extends the building's lifespan and reduces the need for frequent repairs or replacements, thereby providing a cost-effective long-term solution. Additionally, aluminum profiles can be easily recycled, contributing to sustainable construction practices.</p>

Send your message to us

Aluminum Profiles for Solar Panel Frame - Aluminium Profile Extrusion 6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords