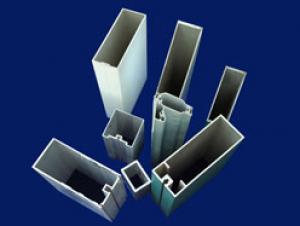

Aluminum Profiles for Glass - Industrial Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: This question asks for the various types of aluminum profiles that are utilized in roofing systems.

- <p>Aluminum profiles for roofing systems come in various types, each serving specific purposes. Common types include: 1. <strong>Gutter Profiles</strong>: Used for collecting and directing rainwater from the roof. 2. <strong>Fascia Profiles</strong>: Cover the ends of rafters and provide a finished edge to the roof. 3. <strong>Soffit Profiles</strong>: Installed under the eaves to allow ventilation and conceal the underside of the roof. 4. <strong>Purlin Profiles</strong>: Support the roof sheeting and are placed perpendicular to the rafters. 5. <strong>Rafter Profiles</strong>: Mimic traditional wooden rafters and provide structural support. 6. <strong>Roof Ridge Profiles</strong>: Cap the ridge of the roof, where two slopes meet. 7. <strong>Hip and Valley Profiles</strong>: Used at the intersection of two sloping roof surfaces. Each profile is designed to withstand weather conditions and provide durability, with specific dimensions and shapes tailored to the roofing system's requirements.</p>

- Q: What are the recycling capabilities of aluminum profiles?

- Aluminum profiles have excellent recycling capabilities. They can be easily recycled without losing their quality or properties. The recycling process involves melting the profiles down, removing any impurities, and then casting them into new shapes or products. This recycling process can be repeated indefinitely, making aluminum profiles a highly sustainable and eco-friendly material.

- Q: Can aluminum profiles be used in automotive applications?

- Yes, aluminum profiles can be used in automotive applications. Aluminum profiles are lightweight, strong, and corrosion-resistant, making them suitable for various automotive components such as body panels, chassis parts, and engine components. Their use helps reduce the overall weight of the vehicle, improving fuel efficiency and performance.

- Q: This question asks for a list of various materials that are used in the production of aluminum profiles.

- <p>Aluminum profiles are primarily made from aluminum alloys, which are composed of aluminum combined with other elements to enhance their properties. Common materials used include 6063 aluminum alloy, known for its excellent extrudability and weldability, making it ideal for a wide range of applications. 6061 aluminum alloy is also used for its high strength and good corrosion resistance, suitable for structural components. Other alloys such as 6082 and 7075 are utilized for their superior strength-to-weight ratios, often found in aerospace and automotive industries. Additionally, aluminum profiles may incorporate materials like magnesium, silicon, copper, and manganese to achieve specific mechanical properties or corrosion resistance tailored to particular applications.</p>

- Q: Can aluminum profiles be used for electrical busbars?

- Yes, aluminum profiles can be used for electrical busbars. Aluminum is a commonly used material for busbars due to its high electrical conductivity, low cost, and lightweight nature. Aluminum profiles provide a reliable and efficient solution for electrical distribution in various applications, including power distribution systems, switchboards, and control panels. They offer good thermal conductivity, which helps in dissipating heat generated during high current flow. However, it is important to consider factors such as current carrying capacity, mechanical strength, and electrical insulation requirements while selecting aluminum profiles for busbar applications.

- Q: This question asks for a comparison between aluminum profiles and other materials regarding their visual appeal and aesthetic qualities.

- <p>Aluminum profiles are often favored for their sleek, modern appearance and high aesthetic value. They offer a clean, silvery finish that can be anodized or painted to match various design schemes. Compared to materials like wood, they provide a contemporary look, while their uniformity and precision in manufacturing can surpass the natural variations found in wood. When compared to plastics, aluminum profiles offer a more premium feel and are often perceived as more durable and high-quality. Additionally, aluminum's recyclability and low maintenance requirements contribute to its eco-friendly and aesthetic appeal in sustainable design.</p>

- Q: Which aluminum profile is better here in Guangdong?

- I think it should be a male aluminum bar, doing things very reassuring, things are also very good. Satisfied, please adopt ha!

- Q: Is it possible to tailor aluminum profiles to fulfill particular design and aesthetic needs?

- <p>Yes, aluminum profiles can be customized to meet specific aesthetic requirements. Manufacturers offer a variety of finishes, colors, and surface treatments to enhance the visual appeal of aluminum profiles. Additionally, the profiles can be cut, bent, and shaped to fit unique design specifications. This customization allows for a high degree of flexibility in creating structures and designs that are both functional and visually appealing, making aluminum profiles suitable for a wide range of applications from architectural to industrial design.</p>

- Q: How do aluminum profiles perform in terms of impact resistance?

- Known for their excellent impact resistance, aluminum profiles are able to withstand significant impact without becoming easily deformed or damaged, thanks to their inherent strength and durability. The ideal strength-to-weight ratio of aluminum makes it particularly suitable for industries such as automotive, aerospace, and construction, where impact resistance is crucial. In addition, the structure of aluminum profiles allows them to absorb and distribute impact energy, thereby preventing localized damage. This property proves especially advantageous in situations that require resistance to sudden shocks, collisions, or heavy loads. Moreover, aluminum profiles can be customized with specific reinforcements or structural elements to further enhance their impact resistance. This flexibility allows for meeting specific requirements or addressing areas prone to impact. In summary, the exceptional impact resistance of aluminum profiles makes them highly valued in industries and applications where strength and durability are essential.

- Q: Are aluminum profiles suitable for electrical grounding applications?

- Yes, aluminum profiles are suitable for electrical grounding applications. Aluminum is a highly conductive material that allows for efficient flow of electrical current, making it an ideal choice for grounding systems. Additionally, aluminum profiles offer excellent corrosion resistance, durability, and cost-effectiveness, making them a reliable option for electrical grounding applications.

Send your message to us

Aluminum Profiles for Glass - Industrial Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords