500 Ft Heavy Duty Aluminum Foil Tape T-F3001FR HVAC Insulation Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

1) High tensile strength aluminum foil made from special aluminum

alloy, coated with aggressive solvent-based acrylic adhesive,

which provides high peel adhesion and quick sticking

2) Designed for sealing joints and seams of foil jacketing in

air-conditioning duct work

3)Excellent Peel Adhesion

4)Good Initial Tack & Permanent Bonding

5)Good Water & Fire Resistance

6)Outstanding Temperature & Aging Resistance

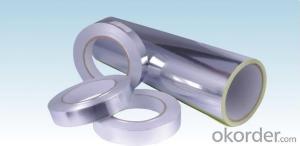

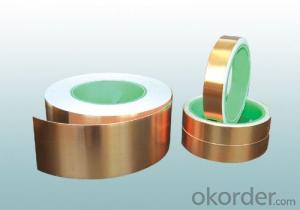

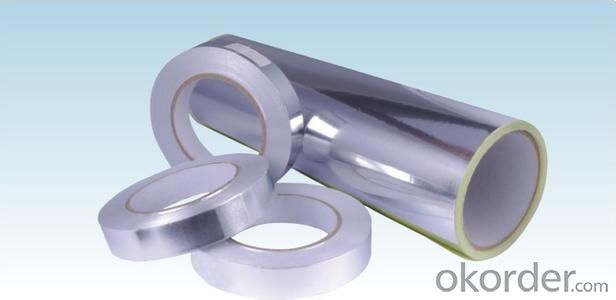

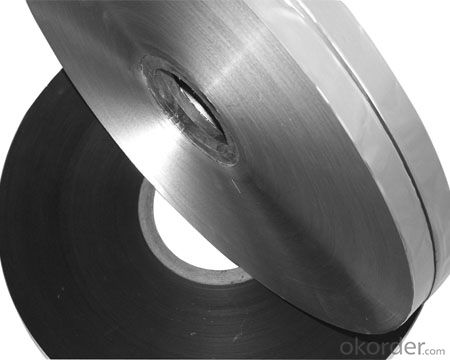

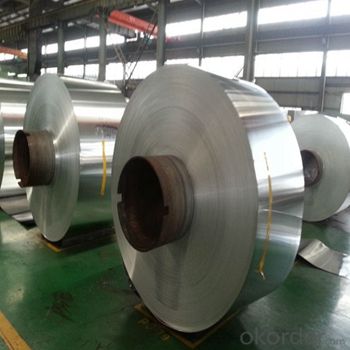

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

1) Foil thickness: 18, 22, 26μ

2) Roll width: 48, 50, 60, 72, 75, 96, 100mm

3) Roll length: 27, 30, 45, 50m

4) Log roll: 1.2 x 45m, 1.2 x 50m

5) Jumbo roll: 1.2 x 1200m, 1.2 x 1000m

5.FAQ

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: Cut Roll: ±0.3m, Jumbo Roll ±0.5%.

3. The product should be stored at room temperature and kept from wet and heat source.Shelf life: One year from shipment date when stored at 21°C (70°F) / 50% relative humidity out of direct sunlight.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q: Not including things you recycle!!im just curiousi decided to check mine and i was surprised!just estimate, don't actually check your rubbish!

- Some plastic packaging, and it takes about 2 weeks to fill the bag The rest gets composted or recycled.

- Q: I am working on a small project using FIMOI have made it into the shape that I require but the trouble is it is stuck to the item that it will eventually be attached toThe FIMO is too thin to be able to peel it off without it breaking upI need to somehow cure the FIMO so that I can remove it but I cannot put this item into the oven as it is made of plastic/vinyl materialI am currently using a hairdryer to heat parts of it for a short time without melting the object it is attached to, is this the best way to do it? Even if I was able to remove the FIMO from the object, it wouldn't be possible to support it well enough in an oven without the shape becoming distorted.

- The hairdryer seems like the easiest choice and I think that this should work since the FIMO is thinBut also try a heat gun, but I understand there's a chance to damage the plastic item And another idea is is you can peel off the FIMO, then you can create a support to hold its shape while bakingTo do this, crumple up some aluminum foil and try to re-create the shape of the plastic item, then transfer the FIMO into thisYou might need to re-sculpt any tears as you transfer to the foil.

- Q: How can aluminum foil and aluminum membrane be distinguished?

- Three, handle: packaging aluminum foil is hard, crisp feel thick and heavy, hand packing aluminum film than is light and soft aluminum foil packaging.Four, folding aluminum foil packaging easy folding dead dead fold marks, aluminum package can not folded pleat die India, and will soon rebound.Five, twist and twist: foil packaging, twisting, coalescence is not easy to rebound, the aluminum layer will fracture. Aluminized film packaging, twisting will soon kink, will be scattered, the aluminum layer will not have obvious cracks.

- Q: A parallel-plate capacitor is made from two aluminum-foil sheets, each 3.90 cm wide and 10.3 m longBetween the sheets is a mica strip of the same width and length that is 0.0225 mm thickWhat is the maximum charge that can be stored in this capacitor? (The dielectric constant of mica is 5.4, and its dielectric strength is 1.00 108 V/m.) Please help soonI feel like this should have been easy, but its not.

- Aluminum is what burns or combines with oxygenLearn How, you have it backwardsIron oxide is the oxidizer.

- Q: how to repair damaged hair? by flat iron, and blow dryer?

- I give them a 5 star rating It is the most cost effective method of moving today I suggest planing on placing the furniture on the bottom, the light stuff on top, and the breakables surrounded by soft thingsIt sounds simple, but it is notDesignate one person as the main pod packer Mark all boxes with contents, and suggested roomFor boxes, hit WalMart in the late eveningsIf you call ahead, they will tell you when to come byFor books, I suggest the 3 gallon water boxesJust big enough to pack full and not be too heavyThey also stack nice Buy several tape guns, and the cheap $1 tape rolls12 should do for an average size house.

- Q: What would be the best:to weld a bike frame to a trike chassis (same metal)orto build a new frame entirely (including the more complex bits such as the pedal axle and handlebar tube)?Any advise on welding the pedal axle hub thing from an old bike to a newly built frame?

- If you are using an aluminum bike frame as a basis do NOT weld anything onto itIf you are using a steel frame then you MIGHT be able to convert itbut there is no way 3 adults will be able to ride itno more than 3 adults could ride the bike in its original formYou are trying to do something that takes some significant knowledge in engineering and some very fancy fabricating (machining) workI am a master builder, have built trikes before and it is definitely not for those who don't have an intimate understanding of making fabrications with thin walled tubing with a good dose of structural engineering whether it be through school or experienceIt is also important to get your terminology correctThe pedal axle is the bottom bracket (which comes in a variety of sizes that you'll have to determine) and the handlebar tube is either the fork steerer or the head tube (I can't decide which one you mean)There is also the seat tube (which has to be reamed for a particular size) as well as close attention paid to the head tube angle, the bottom bracket drop, and the chainline among dozens of other detailsAll the bits you need- including tubing- are generally available from various specialist shops onlineDo NOT use the pedal axle thing from an old bike for a new frameIf you want to look at a couple of custom trike frames, consider searching for Bob Jackson Cycles in Leeds England, and I think Mel Pinto Imports still has one lying around.

- Q: Can I make recycled paper foam like you get at a fastfood resauraunt?

- I would say cottonIt's very soft to the touch and wool can tend to be scratchyIf wool itches adults, imagine how uncomfortable it is to a baby.

- Q: What's the difference between aluminum foil bags and aluminum foil bags?

- The aluminized film is a vacuum coating on the substrate with a thin (about 300nm) aluminum layer. Generally do not use retort bag. There are two reasons:1, general aluminized film can not withstand the temperature of high temperature sterilization, at high temperature, the aluminized layer will be oxidized and black.2 aluminum plating film adhesion is very poor, peel strength can not meet the requirements of cooking bags.

Send your message to us

500 Ft Heavy Duty Aluminum Foil Tape T-F3001FR HVAC Insulation Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords