Aluminum Corrugated Sheets for Cookware and Lighting Cover

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description of Aluminium Circle for Cookware, Lighting Cover

Alloy: 1050, 1070, 1100, 3003, etc

Thickness: 0.5mm~4mm

Temper: O, H14

Diagonal: 100mm - 1200mm

2. Application of Aluminium Circle for Cookware, Lighting Cover

Aluminium Circle is widely used for kitchen wares including fried pans, non-sticky pans, cooking pots, hard anodize cook ware, pressure cooker and house hold utensils etc.

3. Feature of Aluminium Circle for Cookware, Lighting Cover

Aluminium Circle has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

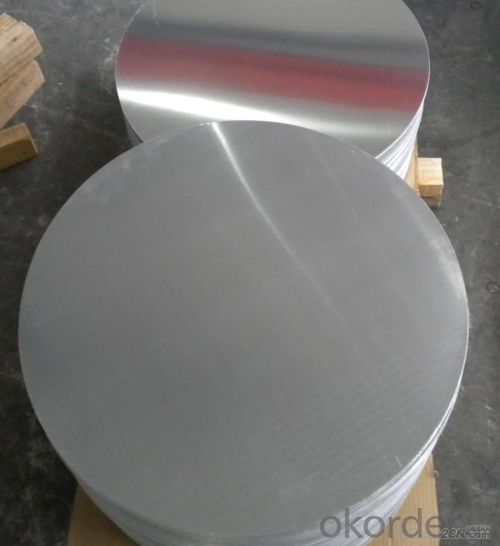

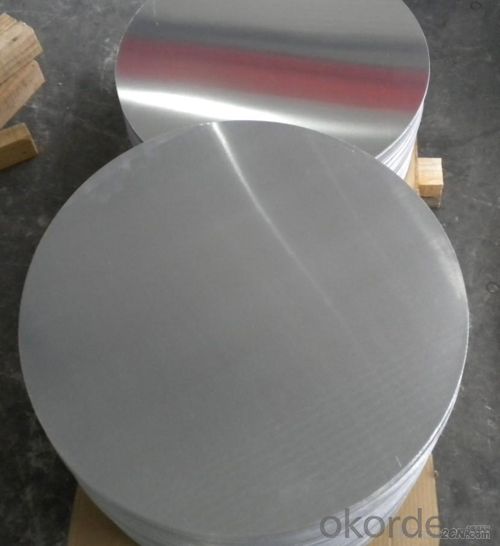

5. Image of Aluminium Circle for Cookware, Lighting Cover

6. Package and shipping of Aluminium Circle for Cookware, Lighting Cover

eye to Sky

eye to wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

- Q: I am doing a report on machining aluminum and characteristics of aluminum and can not find what the 6061 stock stands for. Looked all over library, internet, etc.

- Death Cab For Cutie's What Sarah Said: And It Came To Me Then That Every Plan Is A Tiny Prayer To Father Time As I Stared At My Shoes In The Icu That Reeked Of Piss And 409 And I Rationed My Breathes As I Said To Myself That I'd Already Taken Too Much Today As Each Descending Peak Of The Lcd Took You A Little Farther Away From Me Away From Me Amongst The Vending Machines And Year-old Magazines In A Place Where We Only Say Goodbye It Stung Like A Violent Wind That Our Memories Depend On A Faulty Camera In Our Minds But I Knew That You Were A Truth I Would Rather Lose Than To Have Never Lain Beside At All And I Looked Around At All The Eyes On The Ground As The Tv Entertained Itself 'cause There's No Comfort In The Waiting Room Just Nervous Pacers Bracing For Bad News And Then The Nurse Comes Round And Everyone Will Lift Their Heads But I'm Thinking Of What Sarah Said That love Is Watching Someone Die

- Q: Are the aluminum sheets suitable for manufacturing automotive fuel tanks?

- Yes, aluminum sheets are suitable for manufacturing automotive fuel tanks. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for fuel tank manufacturing.

- Q: What are the different alloys available for aluminum sheets?

- Aluminum sheets offer a range of options when it comes to alloys, each with its own distinct properties and uses. Let's take a look at some of the most commonly used alloys: 1. 1100: This alloy is pure aluminum and boasts exceptional resistance to corrosion. It is perfect for applications that demand high levels of protection against corrosion, such as marine environments. 2. 3003: Another alloy that is purely aluminum, 3003 offers good formability, moderate strength, and high resistance to corrosion. It finds its place in general sheet metal work, chemical equipment, and cooking utensils. 3. 5052: Known for its impressive fatigue strength and outstanding resistance to corrosion, especially in saltwater settings, this alloy is often employed in marine applications, as well as aircraft components and fuel tanks. 4. 6061: As a heat-treatable alloy, 6061 showcases excellent weldability and formability, along with elevated strength and superb corrosion resistance. It is commonly utilized in structural components like frames, railings, and automotive parts. 5. 7075: This alloy stands out for its remarkable strength-to-weight ratio, making it perfect for aerospace applications and structural components that face high levels of stress. However, it is less resistant to corrosion than other alloys and may require protective coatings in specific environments. These examples represent only a fraction of the aluminum sheet alloys available. The choice of alloy relies on the specific requirements of the application, considering factors such as strength, corrosion resistance, formability, and cost. It is crucial to consult a knowledgeable supplier or engineer to determine the most appropriate alloy for your particular needs.

- Q: Dear all, i'm having crack problem with bending aluminium sheet metal, anyone know than which type(Model) of aluminium sheet metal is suitable for bending, Thanks.

- Aluminium sheets is not too difficult to bend, but should use a good bending maschine. The thicker the sheet is the bigger the bend radius must be. Experiment with small pieces until u find the radius where it does not crack anymore. WAY different to steel or copper that can be bent into sparp radiuses l l _____________) radius

- Q: This question asks for a comparison between aluminum sheets and other roofing materials, highlighting their differences.

- <p>Aluminum sheets differ from other roofing materials such as asphalt shingles, clay tiles, and metal roofs in several ways. They are lightweight, durable, and resistant to corrosion, making them ideal for coastal areas. Aluminum sheets offer a sleek, modern aesthetic and can be easily recycled, contributing to their environmental friendliness. Unlike asphalt shingles, which have a shorter lifespan, aluminum sheets are long-lasting and can withstand extreme weather conditions. They also don't require the same level of maintenance as clay tiles, which can crack over time. While metal roofs can be similar to aluminum in terms of durability, aluminum sheets are typically more cost-effective and offer a wider range of colors and finishes.</p>

- Q: Can aluminum sheets be bent into complex shapes?

- Yes, aluminum sheets can be bent into complex shapes due to their malleability and ductility. With the appropriate tools and techniques, aluminum sheets can be formed into intricate and customized designs, making them versatile for various applications.

- Q: Can aluminum sheet be welded?

- Yes, aluminum sheet can be welded.

- Q: Can the aluminum sheets be used for manufacturing solar panel frames?

- Yes, aluminum sheets can be used for manufacturing solar panel frames. Aluminum is a lightweight and durable material that is commonly used in the construction of solar panel frames due to its corrosion resistance and high strength-to-weight ratio.

- Q: What are the common thicknesses of aluminum sheets used in transportation industry?

- In the transportation industry, aluminum sheets are commonly used for various applications due to their lightweight, durability, and corrosion resistance. The common thicknesses of aluminum sheets used in the transportation industry typically range from 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). For applications such as automotive body panels, which require a balance of weight reduction and structural integrity, aluminum sheets with thicknesses of 0.040 inches (1.02 mm) to 0.063 inches (1.6 mm) are commonly utilized. These thicknesses provide sufficient strength while keeping the weight of the vehicle lower compared to steel counterparts. In the aerospace industry, where weight reduction is of utmost importance, thinner aluminum sheets are often used. Thicknesses ranging from 0.025 inches (0.63 mm) to 0.040 inches (1.02 mm) are commonly employed in the construction of aircraft structures, including wings, fuselage panels, and interior components. It is worth noting that the specific thicknesses of aluminum sheets used in the transportation industry can vary depending on the specific application, regulatory requirements, and design considerations. Therefore, it is essential to consult the relevant industry standards and specifications for precise information on the preferred thicknesses for different transportation applications.

- Q: Can 101 aluminum sheets be used in electrical or electronic components?

- Yes, 101 aluminum sheets can be used in electrical or electronic components.

Send your message to us

Aluminum Corrugated Sheets for Cookware and Lighting Cover

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords