Aluminum Coils for Air Conditioners - Aaluminum Foil Induction Seal Liner for HDPE and PET Packers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Details: | Standard export packing or following customer's demand |

Delivery Detail: | Within 10-20days or according to the order quantity |

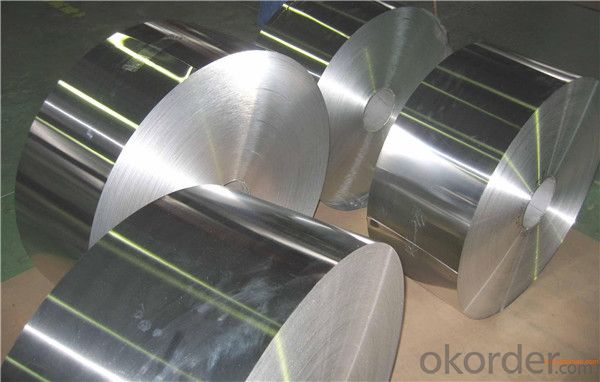

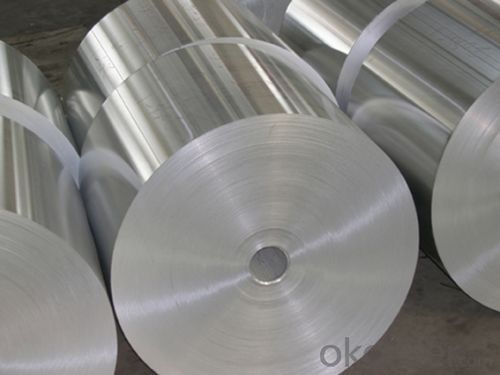

High Quality and Factory Price Aluminum Coil

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Specifications | Width: 30cm,38cm,45cm, OEM; Length: 3m-20m, OEM; Thickness: 10mic-20mic(10mic=10um=0.01mm), OEM; Sizes can be customized according to your requirement; |

| Application |

Supermarkets, catering, hotel, airline, restaurants, household, medical,electronic,chocolate wrapping etc;

|

| Characteristic | 1. Use: suitable for the food packing, barbecue; 2. Color: for food only do sliver color; 3. Inner packing : paper roll core; 4. Box with metal cutter; 5. Surface packing: Color box; |

| NOTES | Our factory can quote to you at the specifications that what you want any time. To undertake all kinds of plastic processing operations. Any sizes and packing can be ordered. Good service and reasonable price.

|

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

Photos

- Q: Is it possible to recycle aluminum coils in various countries around the world?

- <p>Yes, aluminum coils can be recycled in many countries around the world. Recycling aluminum is a global practice due to its high value and the energy savings associated with recycling compared to producing aluminum from raw materials. Different countries have their own recycling programs and facilities that handle aluminum waste, including coils. However, the specific regulations and processes for recycling aluminum coils can vary by country, and it's important to check local recycling guidelines to ensure proper disposal and recycling.</p>

- Q: Other than alloys. I'm trying to think of a way I can make an aluminum knife that will hold an edge. One group of researches say they used 60 metric tons of force to realign the molecular structure and give the metal strength equal to steel. I don't have a 60 ton press aha. Would heat treatment plus 10 tons of pressure repeated have a similar affect?

- TRY IT ! DON'T NEED TO ASK .

- Q: What’s the production standard of aluminum coil?

- GB/T3880-2006 mechanical standard GB/T3190-1996 chemical standard

- Q: Are aluminum coils resistant to abrasion?

- Yes, aluminum coils are generally resistant to abrasion.

- Q: How are aluminum coils processed for specific thicknesses?

- Aluminum coils are processed for specific thicknesses through a series of manufacturing steps. The process begins with the casting of molten aluminum into large ingots. These ingots are then rolled out into thin sheets using a hot rolling mill. The first step in achieving the desired thickness is hot rolling. The aluminum sheet is passed through a series of heated rollers that gradually reduce its thickness. This process is repeated multiple times, with the sheet being reheated between each pass. Hot rolling allows for the sheet to be elongated and thinned out. After hot rolling, the sheet may undergo a process called cold rolling. Cold rolling involves passing the hot rolled sheet through a set of cold rollers. This process further reduces the thickness and improves the surface finish of the aluminum. Cold rolling also increases the strength and hardness of the material. Next, the sheet is annealed, which involves heating it to a specific temperature and then allowing it to cool slowly. Annealing helps to relieve any internal stresses and improve the overall ductility of the aluminum. Once the desired thickness is achieved, the aluminum sheet is typically cut into coils using a slitting machine. The coils can then be further processed or used in various applications, such as in the manufacturing of automotive parts, packaging materials, or building construction. Overall, the process of processing aluminum coils for specific thicknesses involves hot rolling, cold rolling, annealing, and slitting. These steps ensure that the aluminum sheet meets the required thickness specifications and is ready for further use in various industries.

- Q: This question asks for the distinctions between two forms of aluminum used in various industries: coils and sheets.

- <p>Aluminum coil and aluminum sheet are both flat aluminum products but differ in form and usage. Aluminum coil is a long, continuous roll of aluminum that can be easily cut to length and is often used for manufacturing processes like stamping, bending, and forming. It's ideal for applications requiring a consistent and uniform supply of material. On the other hand, aluminum sheet is a flat, rectangular piece of aluminum with a specific thickness, width, and length. It is used for applications where a single piece of material is needed, such as in construction, signage, and decorative purposes. The main difference lies in the form factor and the way they are used in manufacturing and construction processes.</p>

- Q: If you were to make something from each of these.which is more expensive? aluminum or carbon fiber ?which is stronger?What would the advantages or disadvantages of each be?

- This Site Might Help You. RE: aluminum vs carbon fiber ? If you were to make something from each of these. which is more expensive? aluminum or carbon fiber ? which is stronger? What would the advantages or disadvantages of each be?

- Q: How are aluminum coils used in insulation applications?

- Aluminum coils are commonly used in insulation applications as they are lightweight, durable, and have excellent thermal conductivity properties. They are typically used to create a radiant barrier or reflective insulation, where they are installed between the outer walls or roofs of a building and the insulation material. The reflective surface of the aluminum coil helps to reflect radiant heat away from the building, reducing heat transfer and improving energy efficiency. Additionally, aluminum coils are also used in HVAC systems to create air ducts that ensure proper insulation and prevent heat loss or gain.

- Q: How are aluminum coils manufactured?

- Aluminum coil rolling is the process used to manufacture aluminum coils, which come in various sizes and thicknesses. To begin, aluminum smelting extracts and refines raw aluminum ore into aluminum ingots. These ingots are then heated to a specific temperature, making them malleable for the rolling process. Next, the heated aluminum ingots undergo hot rolling. They are passed through a series of rolling mills that gradually reduce their thickness and increase their length. Multiple rollers are used to achieve the desired thickness and shape, improving the mechanical properties and surface finish of the aluminum. After hot rolling, the aluminum coils go through cold rolling. This further reduces their thickness using cold rolling mills. Cold rolling enhances the dimensional accuracy, surface finish, and mechanical properties of the aluminum, while also increasing its strength and hardness. Once the desired thickness is achieved, the aluminum coils may undergo additional processes like annealing or tempering. Annealing involves heating the coils and slowly cooling them to relieve internal stresses and improve their ductility. Tempering, on the other hand, requires reheating the coils to a specific temperature before rapidly cooling them to enhance their strength and hardness. After these processes, the aluminum coils undergo quality control inspections. They are checked for defects, such as surface imperfections or thickness variations, and any necessary corrections are made. Finally, the aluminum coils are cut into smaller sizes and packaged for distribution to various industries. These coils are used in the manufacturing of automobiles, appliances, construction materials, and packaging. In summary, the manufacturing process of aluminum coils involves smelting, hot rolling, cold rolling, annealing, tempering, and quality control checks. These steps ensure that the aluminum coils meet the required specifications in terms of thickness, strength, and surface finish.

- Q: Are aluminum coils suitable for architectural louvers?

- Yes, aluminum coils are suitable for architectural louvers. Aluminum is a popular choice for louvers due to its excellent corrosion resistance, lightweight nature, and high strength-to-weight ratio. Aluminum coils can be easily formed and fabricated into various shapes and sizes, making them ideal for creating aesthetically pleasing and functional louvers. Additionally, aluminum's durability ensures that the louvers can withstand harsh weather conditions and maintain their structural integrity over time. Overall, aluminum coils are a reliable and versatile material for architectural louvers.

Send your message to us

Aluminum Coils for Air Conditioners - Aaluminum Foil Induction Seal Liner for HDPE and PET Packers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords