Aluminum Coil Wisconsin - Hot Rolled Coil, Cold Rolled Coil, Thick Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Hot Rolled Coil Aluminium Cold Rolled Coil Thick Foil

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Hot Rolled Coil Aluminium Cold Rolled Coil Thick Foil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Hot Rolled Coil Aluminium Cold Rolled Coil Thick Foil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

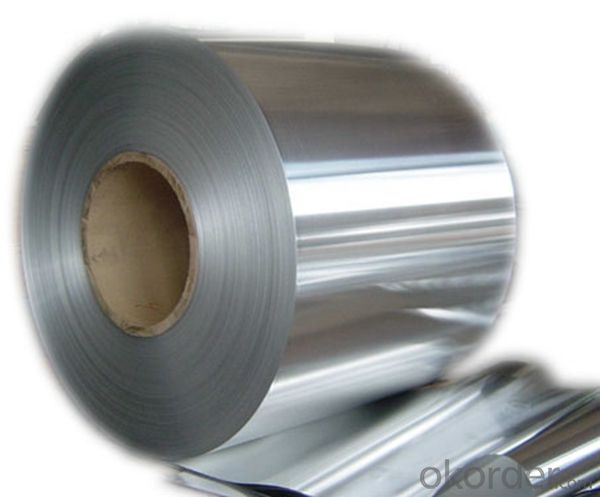

5. Image of Hot Rolled Coil Aluminium Cold Rolled Coil Thick Foil

6. Package and shipping of Hot Rolled Coil Aluminium Cold Rolled Coil Thick Foil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What's the color coated aluminum roll?

- Colour coated aluminium coil product information:Product category: polyester coated aluminum coil (PE), fluorocarbon coated aluminum coil (PVDF)Mylar coated aluminum coilIs a kind of anti UV ultraviolet coating, polyester resin is used in the main chain of ester containing polymer polymer as monomer, add alkyd resin, UV absorber according to gloss, can be divided into sub light and high light series. The utility model is especially suitable for indoor decoration and advertisement boards.Fluorocarbon coating aluminum coilFluorocarbon resin is a kind of fluorocarbon resin, which is composed of pigments, alcohols, esters, solvents and assistants. High temperature barbecue film,The molecular structure of the coating is close and has super weatherability. Fluorocarbon coatings can be divided into two kinds: traditional fluorocarbon and nano fluorocarbon coating according to the surface film forming structure.The utility model is especially suitable for the decoration and display of indoor, outdoor decoration, commercial chain, exhibition advertisement, etc. in public places

- Q: What are the bending and forming capabilities of aluminum coils?

- Aluminum coils have excellent bending and forming capabilities due to their inherent flexibility and malleability. They can be easily bent, shaped, and formed into various complex shapes and designs without losing their structural integrity. This makes them highly versatile and suitable for a wide range of applications in industries such as construction, automotive, aerospace, and manufacturing.

- Q: This question asks for methods to preserve the lifespan of an aluminum coil.

- <p>To maintain an aluminum coil and ensure its longevity, follow these steps: Store the coil in a cool, dry place away from moisture and direct sunlight. Keep it clean by regularly removing dust and debris. Avoid scratching or denting the coil's surface. Handle the coil carefully to prevent damage. Use appropriate lubricants when necessary to reduce friction. Regularly inspect the coil for any signs of corrosion or wear and address these issues promptly. By following these practices, you can extend the life of your aluminum coil and maintain its quality.</p>

- Q: Is it possible to construct a lampshade using an aluminum coil?

- <p>Yes, you can use an aluminum coil to make a lampshade. Aluminum is a lightweight, durable, and heat-resistant material, making it suitable for lampshade construction. You can bend and shape the coil into a desired form and attach it to the lamp base. Ensure proper electrical insulation and avoid direct contact between the coil and the light bulb to prevent overheating. It's advisable to use a professional or follow detailed instructions to ensure safety and a quality result.</p>

- Q: Can aluminum coils be customized or fabricated into specific shapes?

- Indeed, it is possible to customize or fabricate aluminum coils into desired shapes. Aluminum possesses remarkable formability and can be effortlessly shaped through diverse fabrication techniques such as rolling, bending, stamping, and extrusion. By employing these processes, aluminum coils can be converted into specific forms like sheets, plates, tubes, and profiles to cater to the unique demands of different applications. Moreover, aluminum can also be welded, joined, or cut to further tailor its shape and dimensions. The adaptability of aluminum coils in terms of customization renders them highly favored across various industries, including automotive, aerospace, construction, and manufacturing.

- Q: How to remove the fingerprint and glue residue on the color aluminum coil?

- Try to use essential balm. We often use the essential balm to remove glue residue on the stainless steel bowl and basin.

- Q: Can aluminum coils be customized to specific thicknesses and widths?

- Yes, aluminum coils can be customized to specific thicknesses and widths.

- Q: How are aluminum coils stored in a warehouse?

- Aluminum coils are typically stored in a warehouse in a way that ensures their protection and easy accessibility. The coils are usually stacked in rows, either vertically or horizontally, depending on the available space and the weight of the coils. To prevent damage and maintain their shape, the coils are often stored on pallets or racks that provide support and stability. Additionally, the coils may be wrapped in protective materials such as shrink wrap or plastic sheets to shield them from dust, moisture, and other potential hazards. Proper labeling and organization are also crucial to facilitate inventory management and efficient retrieval. Overall, the goal of storing aluminum coils in a warehouse is to maximize space utilization, minimize the risk of damage, and ensure their readiness for shipment or further processing.

- Q: Is it possible to use an electric stove with an aluminum coil heater?

- <p>Yes, you can use an electric stove with an aluminum coil heater. However, it's important to ensure that the aluminum coil heater is designed for use with an electric stove. Aluminum is a good conductor of heat and can be used in heating elements. Make sure the heater is compatible with the stove's power requirements and that it's installed correctly to avoid any safety hazards. Always follow the manufacturer's instructions for installation and use.</p>

- Q: What are the different types of edge conditions for aluminum coils?

- There are several types of edge conditions for aluminum coils, including slit edge, mill edge, deburred edge, round edge, and beveled edge. Each type has specific characteristics and is used for different applications in industries such as construction, automotive, and aerospace.

Send your message to us

Aluminum Coil Wisconsin - Hot Rolled Coil, Cold Rolled Coil, Thick Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords