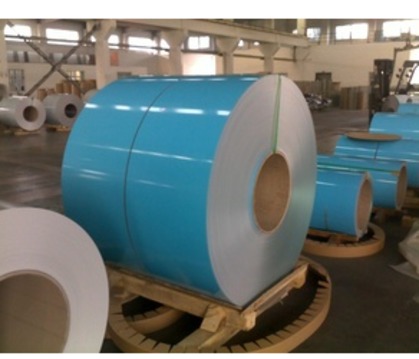

Flat Aluminum in Coils (500-2000kgs Available)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Coil of 500-2000kgs Avaliable for Customer :

Mill Finished Aluminum Coil is designed for many field such as electronics, instruments, lighting decoration, packing industry, and house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel, aluminum composite pipe etc.. Mill finished aluminum coil for is hard and everlasting under the blazing sun. You can choose the alloys as your habitation and we will do our best to meet your requests.

2.Main Features of the Aluminum Coil of 500-2000kgs Avaliable for Customer:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminum Coil of 500-2000kgs Avaliable for Customer

Alloy: | AA1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006 |

Temper: | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness: | 0.2-100mm |

Width: | 30mm-1700mm |

4. Production of Aluminum Coil of 500-2000kgs Avaliable for Customer

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: What is the tensile strength of aluminum coils?

- The tensile strength of aluminum coils can vary depending on the specific alloy and temper used. However, on average, aluminum coils have a tensile strength ranging from 150 to 300 megapascals (MPa). This means that aluminum coils can withstand a pulling force of 150 to 300 MPa before breaking or deforming. It is important to note that the tensile strength may be influenced by factors such as the thickness of the coil, the manufacturing process, and any additional treatments or coatings applied to the aluminum.

- Q: This question asks for methods to check if an aluminum coil has been damaged during the transportation process.

- <p>To determine if an aluminum coil is damaged during transportation, inspect it visually for any dents, scratches, or deformations. Check for any signs of rust or corrosion, which could indicate exposure to moisture. Ensure the coil is clean and free from any foreign materials that might have adhered during transit. Use a magnetic particle inspection or dye penetrant testing for more detailed internal and surface inspections, especially if the damage is not visible. Additionally, measure the coil's dimensions to ensure they are within the specified tolerances. If the coil is part of a shipment, also review the transportation records for any incidents that might have caused damage.</p>

- Q: Can aluminum coils be used in the production of beverage cans?

- Certainly, beverage cans can indeed be produced using aluminum coils. Aluminum is the preferred material for manufacturing beverage cans due to its lightweight nature, durability, and ability to maintain the taste and quality of the contents. Typically, aluminum coils are employed in the canning process as they can be readily molded into the desired can shape. These coils are rolled into sheets, which are subsequently cut and transformed into cans. Additionally, aluminum coils possess exceptional heat conductivity, enabling efficient cooling and faster production rates. All in all, aluminum coils play a crucial role in the production of beverage cans and are extensively utilized within the industry.

- Q: Is it safe and effective to use aluminum coil for baking purposes?

- <p>Yes, aluminum coil can be used for baking. It is a common material in baking due to its excellent heat conductivity, which allows for even heating and browning of baked goods. However, it's important to ensure that the aluminum coil is food-grade and clean to avoid any contamination. Additionally, some people may be concerned about potential health risks associated with aluminum, although these concerns are generally considered minimal when using aluminum cookware for baking.</p>

- Q: We have all heard the Us saying aluminum and their euro counterparts saying aluminium. I assumed this was just a small difference in culture or location. But, while reading my chemistry book (Chemistry the Central Science 12th) i came across a section saying: Cations formed from nonmetal atoms have names that end in -ium: NH4+ ammonIUM ion, H3O+ hydronIUM ion. So, i have came up with a hypothesis, could it be possible that when the periodic table was coming together, the aluminium was changed to aluminum to allow the rules to work? Thus making aluminum the correct spelling? Give me your thoughts.

- It just depends on which side of the Atlantic Ocean you live. Come to think of it though, most metals end in ium. Not just the ions.

- Q: What are the various applications of aluminum coil in the construction industry?

- <p>Aluminum coil is widely used in construction for various purposes due to its lightweight, durability, and corrosion resistance. It is commonly used in roofing and siding materials for both residential and commercial buildings, providing a long-lasting and low-maintenance option. Aluminum coil is also utilized in the manufacturing of window frames and doors, offering thermal efficiency and strength. Furthermore, it is used in the production of heat exchangers, solar panels, and electrical wiring due to its excellent conductivity. Additionally, aluminum coil is employed in the fabrication of scaffolding and structural components, contributing to the overall stability and safety of construction projects.</p>

- Q: Are aluminum coils suitable for marine applications?

- Yes, aluminum coils are suitable for marine applications due to their excellent corrosion resistance properties in saltwater environments.

- Q: What is the typical thickness tolerance for aluminum coils?

- The thickness tolerance for aluminum coils can vary based on specific requirements and industry standards. Generally, the tolerance falls within a range of +/- 0.002 to 0.005 inches. This means that the actual thickness of the aluminum coil can deviate from the specified thickness by a maximum of either 0.002 or 0.005 inches, depending on the tolerance requirements. It's worth noting that these tolerances can also be expressed as a percentage of the specified thickness, typically ranging from 4% to 8%. These tolerances ensure that the aluminum coil thickness aligns with desired specifications and allows for an acceptable level of variation for the intended application.

- Q: Is aluminum silicate roll felt the same as aluminum silicate acupuncture blanket?

- No, the unit weight of aluminum silicate fiber felt is greater than that of aluminum silicate acupuncture blanket. Both are thermal insulation and fire-proof material and have the same function.

- Q: I'm trying to cast aluminum using plaster and i was wondering if any one know how much the plaster has to be baked and how to tell if the plaster is dried fully and ways to do it. thx

- Plaster releases water at two points - in ordinary or accelerated drying it loses the water needed for setting and stops feeling cool and feels dry. If it is heated past 900F it loses chemically bound water and may fall apart. Aluminum melts at several hundred degrees higher than this and if the mold is intended to hold a mass of aluminum is is likely to destroy the mold. If the aluminum casting is fairly flat less of a problem. The common method for dealing with this is to add 50% silica flour (bad for lungs warning) to the dry plaster when making the mold. Then the mixed material mold can be used and preheated to take materials at least up to fused/molten glass, although the mold is commonly lost (not reusable) at these temps and just barely holds together.

Send your message to us

Flat Aluminum in Coils (500-2000kgs Available)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords