Aluminum Sheets Flashing AA3105 for Aluminum Trailers Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Sheets AA3105 for Making Aluminium Trailers

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Aluminium Sheets AA3105 for Making Aluminium Trailers

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Sheets AA3105 for Making Aluminium Trailers

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

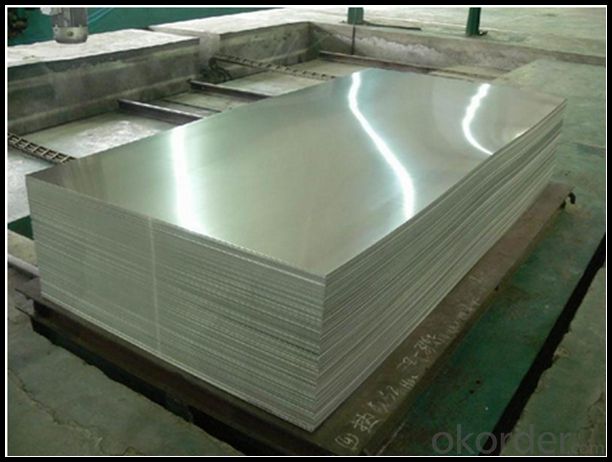

5. Image of Aluminium Sheets AA3105 for Making Aluminium Trailers

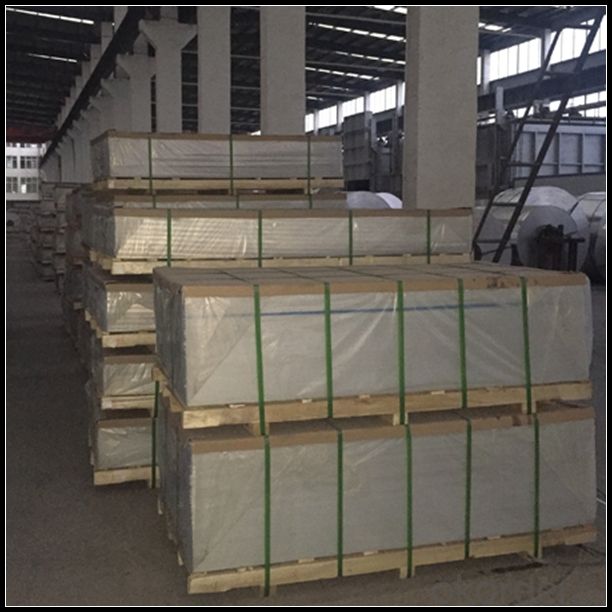

6. Package and shipping of Aluminium Sheets AA3105 for Making Aluminium Trailers

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum sheets perform in extreme temperatures?

- Aluminum sheets generally perform well in extreme temperatures as they have a high melting point and excellent thermal conductivity. This allows them to resist deformation or structural changes under extreme heat or cold conditions. Additionally, aluminum has a low coefficient of expansion, which helps it maintain its shape and integrity under temperature fluctuations. Overall, aluminum sheets are known for their stability and reliability even in extreme temperature environments.

- Q: What is the main influence of the spacing?What are the main effects of spacing?

- Thermal explosion is related to a lot of factors. As to how much impact the lining board has on the thermal explosion, it's really impossible to speak of it. I think it has very little influence

- Q: Can aluminum sheets be used for decorative wall panels?

- Aluminum sheets are indeed suitable for decorative wall panels. As a versatile material, aluminum offers a wide array of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it perfect for both indoor and outdoor applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for limitless design possibilities. Moreover, aluminum can be enhanced in appearance and provided with extra protection against wear and tear through powder-coating or anodizing. Whether it's for residential or commercial spaces, aluminum sheets can impart a modern and stylish touch to any wall, rendering them a highly sought-after choice for decorative wall panels.

- Q: Are there any health risks associated with using aluminum sheets?

- There is ongoing debate and research regarding the potential health risks associated with using aluminum sheets. While aluminum is a common material used in various industries and products, it is important to consider certain factors. Exposure to high levels of aluminum, such as through inhalation or ingestion, has been linked to health issues. Studies suggest that aluminum exposure may be associated with neurological disorders, such as Alzheimer's disease or Parkinson's disease, as well as respiratory problems and bone disorders. However, it is important to note that these studies have not yet established a definitive causal relationship between aluminum and these health conditions. The primary concern with aluminum is its potential to leach into food or beverages when it comes into contact with acidic or salty substances. This leaching can occur during food preparation or storage, especially if using aluminum cookware or foil. Consuming high levels of aluminum through food or drink may pose health risks, particularly for individuals with kidney disease or those who have a higher susceptibility to aluminum toxicity. To mitigate potential health risks, it is recommended to avoid using aluminum cookware or foil when cooking or storing acidic or salty foods. Instead, consider using alternatives such as stainless steel, glass, or silicone. In conclusion, while there are concerns about the potential health risks associated with using aluminum sheets, more research is needed to establish a clear cause-and-effect relationship. It is prudent to minimize exposure to aluminum, especially through food and beverages, by adopting preventive measures and using alternative materials when appropriate. Consulting with health professionals and staying updated on the latest research can help individuals make informed decisions about using aluminum sheets and other aluminum products.

- Q: Can someone explain the movement of electrons in a pure block of aluminum metal? At they free to move around between similar energy levels? Are they bound to Al atoms? What about orbital overlap?

- Any element that allows the transfer of electrical flow to move across it usually has the characteristic of having free movement electrons in the outer shell. This is why metals are particularly good at electrical conduction. The best metal for transferring electrical charge is silver followed by copper and then aluminum. Much electrical wire is made from pure aluminum because it is cheaper than copper or silver and the resistance to flow is only slightly lower than copper. The electrons in the outer shells are still bound to the aluminum nucleus but they are free to accept a charge from neighboring aluminum atoms and transfer that charge to the next aluminum in the electrical flow. This is basically the definition of electrical resistance. Copper performs this transfer more efficiently than aluminum so it's electrical resistivity is less than aluminums. But in both base metals, the outer electrons never leave the atom, they simply transfer their charge to the next atom in line

- Q: What are the semi hard ones? What are the alloys? What are the anti rust ones, such as 3003505210606061, 7075?

- 3003: board. Strip foil. Tensile plate, tube. Extrusion tube. Type. Rod. Rod. Cold bar, cold wire, rivet wire, forging, foil, heat sink material mainly used for processing requires good molding property, high corrosion resistance, good weldability and spare parts not only have these requirements, or performance need than the workpiece of 1*** alloy with high strength, such as transportation of liquid tank and tank, pressure tank, storage device, heat exchanger, chemical equipment, aircraft fuel tank, oil pipe, reflective panels, kitchen equipment, cylinder washing machine, rivet, welding wire.3003 aluminum alloy sheet, plate, tube drawing. The extruded tube housing partition, cap, pipe3004 plate, plate, pipe extrusion tube for tensile. As long as the whole aluminum cans cans, for more than 3003 alloy parts, chemical products production and storage device, sheet processing, building baffle, cable conduit, sewer, various lighting components.3004 aluminum alloy sheet, plate mainly used for housing partition, baffle, sewer, the roof of industrial plant5052 plate, plate, sheet, foil, drawing tube, cold processing bar, cold wire, rivet wire, this alloy has good shaping property, high corrosion resistance, weldability and fatigue strength, medium static strength, used in the manufacture of aircraft fuel tank, tubing, and vehicles, sheet metal parts, ship the instrument, street lamp and rivet wire and so on.

- Q: Can aluminum sheets be used for air ducts?

- Yes, aluminum sheets can be used for air ducts. Aluminum is a commonly used material for air ducts due to its lightweight, durable, and corrosion-resistant properties. It is also easy to work with and can be easily shaped and formed to fit various duct designs.

- Q: What are the standard sizes and availability of aluminum sheets in the market?

- The sizes and availability of aluminum sheets in the market can vary depending on the location and specific requirements. Nevertheless, there are generally available sizes that can be found in most markets. In terms of thickness, aluminum sheets are commonly found in the range of 0.02 to 0.2 inches (0.5 to 5 millimeters). Thinner sheets (0.02 to 0.06 inches) are often utilized for lightweight purposes such as signage or crafts, while thicker sheets (0.1 to 0.2 inches) are typically employed for more heavy-duty applications like construction or industrial use. Regarding width and length, standard sizes of aluminum sheets are often offered in 4 feet by 8 feet (48 inches by 96 inches) or 4 feet by 12 feet (48 inches by 144 inches). These dimensions are widely available and suitable for various applications. However, it is important to note that custom sizes can also be ordered or cut from larger sheets to meet specific project requirements. Aluminum sheets can be found in various locations, including local hardware stores, metal suppliers, and online marketplaces. It is always advisable to check with local suppliers or conduct online research to determine the specific sizes and availability in your area. Additionally, different grades or alloys of aluminum may have varying availability, so it is crucial to consider the specific requirements of your project when sourcing aluminum sheets.

- Q: project on aluminum and i cant think of a good/funny slogan for it! HELP! i have already seen the other possibilities on google, try to be unique, and creative! but if you cant just answer the flipping question PLZ!

- Aluminum: Keeping stoners amazed for over 50 years!

- Q: Yesterday I picked up an 1988 performance bike. I bought it for the parts. It rode really good and now I'm deciding to keep it as is but I'm wondering if the bike is safe to ride. I've hear of aluminum horror stories and I'm assuming old aluminum isn't asnymore safe.Should I toss the frame and put the parts on a steel frame I have or ride it and not worry about it failing.

- 1988? Why do you believe it is aluminum? So far as I can recall, Performance didn't begin offering bicycles AT ALL until about 1992. Even then they had steel frames... their bikes were supplied by a Taiwanese company by the name of UEC who also made (and makes) KHS brand bikes. Regarding early aluminum failures, yes, there were many simply because factories were unfamiliar with the material and thought they could get away without the post treatment that a welded aluminum structure often requires. Another reason for aluminum frame failure was when a few factories attempted to bond aluminum tubes to lugs. This is also a problem with carbon fiber bikes. This is because the epoxy used degasses, or hardens and becomes crystallized. The now brittle epoxy cracks and results in catastrophic failure. This, in the factory's opinion, was not a warranty event. I'll tell you what. Grab a magnet off of your refrigerator and see if it sticks to the frame. if it does- even a tiny bit- then it is steel. If the frame is WELDED aluminum it should be retired since there is no way of telling whether the frame was properly post-treated. If the frame is BONDED then it should be retired because of the possibility of the epoxy fracturing.

Send your message to us

Aluminum Sheets Flashing AA3105 for Aluminum Trailers Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords