Aluminum Expanded Metal Sheets - Aluminium Plate and Slab with Price in Warehouse with Stocks Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

We are come from CNBM INTERNATIONAL CORPORATION, our mainly products are as follows: aluminum sheet, aluminuim coil, aluminium composite panel, aluminium sandwich panel, aluminum ceiling etc. we can also provide the raw material for producing the above items, please feel free to contact us for detailed quotation, thanks in advance. sheet are widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series,etc. The detailed grade are as follows: 1010,3003, 3005, 3105, etc.

The temper is include H14, H12, H22, H44,O,F TEMPER ,etc.

2. Main features of the product

a. Competitive price

b. Shortest service.

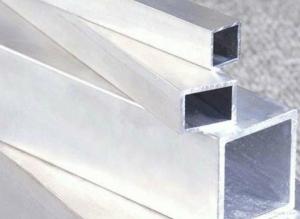

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1250mm*2500mm,at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year

USA, japan, UAE, Vietnam, Canada, etc.

What is your mainly products?

---Normally finish aluminium sheet, aluminum casting coil, etc.

- Q: I am thinking about getting a MacBook Aluminum or a MacBook white. The Aluminum is 2.0 GhZ and the MacBook White is 2.16 GhZ. which should i get? also i am really wondering if you can upgrade the processors in both MacBooks..... Please give me link if you can. THANKS!!

- If okorder /... I'm not sure about the processor's. I dont use Mac that often!

- Q: What is the cost of aluminum sheets compared to other metals?

- The cost of aluminum sheets compared to other metals can vary depending on several factors such as the grade, thickness, size, and market conditions. However, generally speaking, aluminum sheets tend to be more cost-effective compared to other metals. Aluminum is one of the most abundant elements on Earth, making it more readily available and less expensive to produce. Additionally, aluminum has a lower density than many other metals, which means that less material is needed to achieve the same strength and durability. This further contributes to its lower cost. In contrast, metals like steel or titanium may be more expensive due to their scarcity or higher processing costs. However, it's important to note that prices can fluctuate over time due to various economic factors, so it's always recommended to check the current market prices before making any purchasing decisions.

- Q: What is aluminium oxide sheet?

- The oxidation of aluminum in natural and chemical oxidation, and oxidation of several, generally refers to the chemical oxidation oxidation plate plate, is the use of chemical reaction to aluminum formed on the surface of a white coating can reach the anticorrosion effect, can also be made, through technology, color, color, texture

- Q: How do you ensure the surface quality of aluminum sheets?

- To guarantee the surface quality of aluminum sheets, manufacturers can take several steps: 1. Cleanliness is crucial. Prior to any surface treatment or inspection, it is vital to thoroughly clean the aluminum sheets and eliminate any dirt, grease, or contaminants. This can be accomplished using solvents, detergents, or specialized cleaning agents. 2. A visual inspection is necessary. Trained personnel should visually inspect the surface for visible flaws such as scratches, dents, or pitting. Proper lighting and magnification tools should be utilized. 3. Chemical treatments may be required. Depending on the desired surface finish and application, aluminum sheets may undergo chemical treatments such as anodizing, chromate conversion coating, or passivation. These processes can enhance the sheets' surface quality, corrosion resistance, and aesthetic appearance. 4. Mechanical polishing can be employed. To eliminate surface imperfections and achieve a smooth, glossy finish, mechanical polishing techniques like grinding, buffing, or sanding can be utilized. It is important to maintain consistency and avoid over-polishing, which can compromise the integrity of the sheets. 5. Coating and protection are essential. Applying protective coatings like lacquers, paints, or powder coatings can further improve the surface quality, appearance, and durability of aluminum sheets. These coatings act as a barrier against corrosion, abrasion, and environmental factors. 6. Quality control is crucial. Rigorous quality control procedures should be implemented throughout the manufacturing process. Regular inspections, testing, and documentation should be conducted to ensure that the surface quality of aluminum sheets meets the required standards and specifications. 7. Proper handling and packaging are necessary. To prevent surface damage during transportation and storage, it is important to handle and package the sheets correctly. Protective measures such as using protective films, paper interleaves, or cushioning materials should be employed to safeguard the surface quality until the sheets reach their final destination. By following these measures, manufacturers can ensure that the surface quality of aluminum sheets meets the desired specifications and exceeds customer expectations.

- Q: How much is the price of the 6061 aluminum plate?

- Therefore, according to your specifications, quantity and use in what place (that is, quality requirements) in order to quote.Or give you a reference priceMore than 8MM thickness of the domestic low-end (that is, the surface black, flatness is not how kind of) price of 20 yuan /KG or soMade in China at the end of the price of 25-30 yuan /KG, domestic high-end 30 yuan /KG or more.Imports are usually 40-80/KGThe thickness below 8MM is quoted according to the actual thickness

- Q: How are aluminum sheets different from aluminum plate?

- There are two forms of aluminum metal, namely aluminum sheets and aluminum plates, which primarily differ in terms of thickness. Aluminum sheets are usually thin and flat, with a thickness of less than 6mm. They are commonly utilized in situations where lightweight and flexibility are crucial, such as in the fabrication of aircraft, automobiles, and electronic devices. Conversely, aluminum plates are thicker and heavier than sheets, typically measuring 6mm or more in thickness. Plates are frequently employed in applications that necessitate strength and durability, such as in the assembly of heavy machinery, structural supports, and marine equipment. Despite both sheets and plates being composed of aluminum, their distinctive thicknesses render them suitable for distinct purposes.

- Q: Are aluminum sheets suitable for harsh weather conditions?

- Aluminum sheets are highly suitable for harsh weather conditions due to their exceptional properties. Aluminum is a lightweight yet durable material that offers excellent resistance against corrosion, rust, and UV radiation. This makes it particularly resilient against the damaging effects of extreme weather conditions such as heavy rain, snow, high winds, and intense sunlight. Furthermore, aluminum has a high strength-to-weight ratio, allowing it to withstand the pressure exerted by severe weather without sustaining significant damage. Additionally, aluminum sheets can be coated with protective finishes such as anodization or powder coating, further enhancing their ability to withstand harsh climates. Overall, aluminum sheets are an excellent choice for applications requiring resilience in harsh weather conditions.

- Q: What are the dimensions of standard aluminum sheets?

- The dimensions of standard aluminum sheets vary depending on the intended application. However, common sizes for standard aluminum sheets range from 0.02 to 0.249 inches in thickness, 36 to 72 inches in width, and 96 to 144 inches in length.

- Q: How do aluminum sheets perform in high-temperature environments?

- Due to its exceptional thermal conductivity and relatively low melting point, aluminum sheets are highly effective in high-temperature conditions. With a melting point of 660.3°C (1220.5°F), aluminum is able to endure elevated temperatures without melting, unlike many other metals. Furthermore, its remarkable thermal conductivity enables efficient heat dissipation from the surface, preventing overheating and maintaining the integrity of structures. This quality makes aluminum sheets ideal for applications in industries such as aerospace, automotive, and construction, which often encounter high temperatures. However, it is crucial to acknowledge that prolonged exposure to extremely high temperatures can lead to a weakening of aluminum and a reduction in its mechanical properties. Consequently, in extreme high-temperature environments, it may be necessary to explore alternative materials or implement additional protective measures to ensure optimal performance.

- Q: Can the aluminum sheets be used for printing applications?

- Yes, aluminum sheets can be used for printing applications. Aluminum provides a smooth and flat surface, making it ideal for printing graphics, images, and text. The sheets can be easily printed on using various printing methods such as offset printing, screen printing, and digital printing. Printing on aluminum sheets offers durability, resistance to fading and weathering, and a professional and sleek appearance. It is commonly used for signage, labels, nameplates, and decorative purposes in industries like advertising, automotive, aerospace, and packaging.

Send your message to us

Aluminum Expanded Metal Sheets - Aluminium Plate and Slab with Price in Warehouse with Stocks Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords