Aluminum Sheets Kaccha House - Aluminium Coils for Decoration Ceiling AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Coils for Decoration Ceiling AA3003

Aluminium Coils for Decoration Ceiling AA3003 is one semi-finished aluminium material. The coils are widly used in the building,decoration and aluminium circle. The alloy AA1050 is the most common alloy in the aluminium industry. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Decoration Ceiling AA3003

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

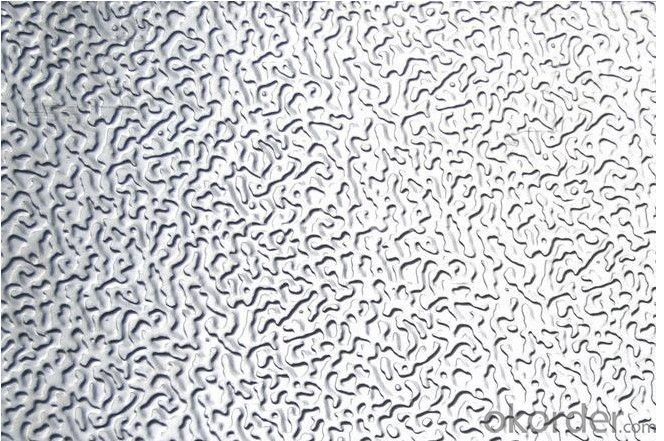

3. Image of Aluminium Coils for Decoration Ceiling AA3003

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA1100 | HO | 0.2MM-3MM | 1000-1500MM | Max 3 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: This question is asking for a list of different types of fasteners that can be used to attach aluminum sheets to a structure.

- <p>There are several types of fasteners used for attaching aluminum sheets to a structure, including: 1. Rivets: These are permanent fasteners that join two pieces by deforming the rivet material. 2. Screws: These are threaded fasteners that can be inserted and removed as needed. 3. Bolts: Similar to screws, bolts are used with nuts to secure aluminum sheets. 4. Adhesives: Chemical adhesives can be used for bonding aluminum sheets without visible fasteners. 5. Welding: Although not a fastener, welding can join aluminum sheets permanently. 6. Clips and Clamps: These are used for temporary or non-structural attachment. 7. Self-tapping screws: These screws create their own threads in the material being fastened. Each type has its own advantages and is chosen based on the specific requirements of the project.</p>

- Q: Is it possible to use aluminum sheets for constructing a sustainable building?

- <p>Yes, aluminum sheets can be used to create a sustainable building due to their recyclability, low thermal conductivity, and durability. Aluminum is a lightweight material that can reduce the energy consumption in transportation and construction. It also has a high recycled content ratio and can be easily recycled, which reduces waste. Additionally, aluminum's low thermal conductivity can contribute to energy efficiency in buildings by reducing heat transfer, thus lowering energy costs for heating and cooling. However, it's important to consider the entire life cycle of the material and ensure that the manufacturing and disposal processes align with sustainable practices.</p>

- Q: How do you prevent scratches during transportation of aluminum sheets?

- To minimize the occurrence of scratches when transporting aluminum sheets, there are several steps that can be taken: 1. Adequate packaging: It is important to securely package the aluminum sheets using suitable materials like bubble wrap, foam, or cardboard. This will offer cushioning and protection against external impacts. 2. Application of protective layers: Inserting paper or plastic film between individual sheets will prevent direct contact and minimize the risk of scratching. 3. Secure stacking: When loading the aluminum sheets onto transportation vehicles, ensure they are stacked securely to prevent any movement or shifting during transit. This can be achieved by using appropriate strapping or palletizing techniques. 4. Gentle handling: Properly train personnel involved in the transportation process to handle the aluminum sheets with care. They should avoid dragging or sliding them against rough surfaces that could cause scratches. 5. Avoid contact with sharp objects: Take measures to ensure that the aluminum sheets do not come into contact with sharp objects or edges. This can be accomplished by keeping them separate from other materials or using protective covers. 6. Regular inspections: Regularly inspect the aluminum sheets during transportation to identify any potential scratches or damages. If any are discovered, immediate action should be taken to prevent further harm. By implementing these preventive measures, the likelihood of scratches occurring during the transportation of aluminum sheets can be significantly reduced. This will ensure that the sheets are delivered in optimal condition to their destination.

- Q: Are the aluminum sheets available in different finishes (e.g., brushed, polished)?

- Aluminum sheets can be obtained in various finishes, such as brushed or polished, providing different surface textures and appearances. These finishes are achieved by employing diverse processes that modify the aluminum sheets. Brushed finishes, for instance, create a textured pattern by delicately brushing the surface with fine abrasive materials, resulting in a satin-like look. Conversely, polished finishes involve utilizing abrasive compounds or polishing wheels to buff the surface to a high shine. Consequently, these distinct finishes enable the customization and versatile utilization of aluminum sheets across different industries.

- Q: What is the typical hardness of aluminum sheets?

- The typical hardness of aluminum sheets can vary depending on the specific alloy and tempering process used, but it generally falls within the range of 40-70 on the Rockwell B scale.

- Q: what will happen when aluminum sheet is put into copper chloride solution?

- the chemical equation of the reaction, 2Al+3CuCl2=2AlCl3+3Cu, the phenomena when aluminum sheet is put into copper chloride solution: there is red solid generating on the surface of aluminum sheet.

- Q: This question asks for the typical dimensions of aluminum sheets utilized in the construction industry.

- <p>The standard size for aluminum sheets used in construction can vary depending on the region and specific application. However, commonly used sizes include 4x8 feet, 4x10 feet, and 5x10 feet. These sheets are typically 0.020 to 0.060 inches thick. It's important to note that custom sizes are also available to meet specific project requirements. Always check with local suppliers or industry standards for the most accurate sizing information.</p>

- Q: Are the aluminum sheets suitable for manufacturing heat exchanger tubes?

- Yes, aluminum sheets are suitable for manufacturing heat exchanger tubes. Aluminum has excellent thermal conductivity, corrosion resistance, and is lightweight, making it an ideal material for heat transfer applications.

- Q: What are the different types of surface treatments available for powder-coated aluminum sheets?

- Some different types of surface treatments available for powder-coated aluminum sheets include anodizing, chemical etching, mechanical polishing, and electroplating. Each treatment offers unique benefits and can enhance the appearance, durability, and corrosion resistance of the aluminum sheets.

- Q: What is the yield strength of aluminum sheets?

- The yield strength of aluminum sheets can vary depending on various factors such as the alloy of aluminum, the tempering process, and the thickness of the sheets. Generally, aluminum sheets have a yield strength ranging from 10,000 psi (69 MPa) to 45,000 psi (310 MPa). However, it is important to note that these values are approximate and can vary based on the specific grade and temper of aluminum being considered.

Send your message to us

Aluminum Sheets Kaccha House - Aluminium Coils for Decoration Ceiling AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords