Aluminum Sheets for Sale Buffalo NY - Aluminium Coil for Air Conditioning Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

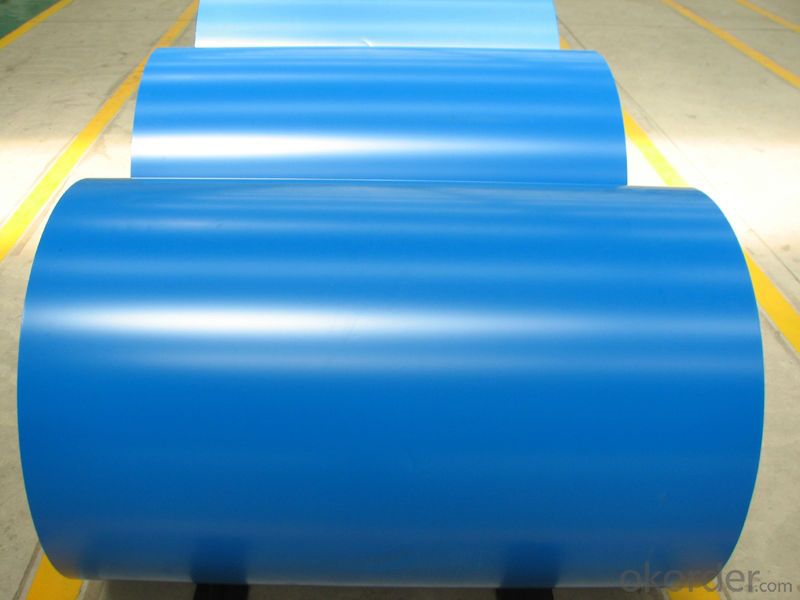

Structure of Aluminium Coil for Air Conditionnal Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coil for Air Conditionnal Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Coil for Air Conditionnal Application:

Aluminium Coil for Air Conditionnal Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Coil for Air Conditionnal Application:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: How do you store aluminum sheets?

- Aluminum sheets should be stored in a dry and well-ventilated area, preferably indoors, to prevent corrosion. They should be stacked horizontally on a flat surface, with a protective covering such as plastic or cardboard between each sheet to avoid scratches. Additionally, it is advisable to separate different gauges or alloys to avoid galvanic corrosion. Regular inspection and maintenance are essential to ensure their longevity.

- Q: How would you write the formula for aluminum sulfate and calcium chloride?

- AlSO4 CaCl

- Q: How do aluminum sheets perform in terms of water resistance?

- Aluminum sheets have excellent water resistance properties. Due to the natural oxide layer that forms on its surface, aluminum is highly resistant to corrosion and effectively prevents the penetration of water. This oxide layer, also known as aluminum oxide, acts as a protective barrier, inhibiting the reaction between aluminum and water molecules. Additionally, aluminum sheets can be further enhanced with different surface treatments, such as anodizing or coating, to improve their water resistance even further. These treatments create a thicker and more durable oxide layer, making the aluminum sheets highly resistant to water damage, moisture, and rust. Overall, aluminum sheets are a reliable choice for applications that require water resistance, ensuring long-lasting performance in various environments.

- Q: Can aluminum sheet be used for architectural applications?

- Yes, aluminum sheet can be used for architectural applications. Aluminum is a versatile material known for its strength, durability, and corrosion resistance. It is commonly used in the construction industry for architectural cladding, roofing, and facades, among other applications. Aluminum sheets are available in various thicknesses, allowing architects and designers to achieve different aesthetic and functional requirements. They can be easily shaped, bent, and formed to create unique architectural elements, such as panels, screens, louvers, and decorative features. Furthermore, aluminum sheets can be coated or finished to enhance their appearance and protect them from environmental factors. Anodizing, powder coating, or painting can be applied to improve the material's resistance to weathering, UV radiation, and pollution. The lightweight nature of aluminum makes it a preferred choice for architectural applications as it reduces the overall weight of the structure and facilitates easier installation. Additionally, aluminum is a sustainable material that can be recycled indefinitely, making it an environmentally friendly option for architectural projects. In conclusion, aluminum sheets are a viable and popular choice for architectural applications due to their strength, versatility, durability, and aesthetic appeal.

- Q: Can aluminum sheets be easily shaped or bent?

- Indeed, aluminum sheets possess a remarkable capability to be effortlessly molded or flexed. Renowned for its exceptional malleability and ductility, aluminum exhibits a remarkable propensity to be readily fashioned into diverse contours and curves. The manipulation of this versatile metal can be accomplished through an assortment of techniques, encompassing rolling, pressing, and even manual utilization of tools. Given its pliability, aluminum emerges as the preferred choice within industries such as automotive, aerospace, and construction, wherein the fabrication of intricate shapes and bends is a common necessity. Moreover, the lightweight nature and inherent resistance to corrosion further enhance aluminum's suitability for shaping and bending endeavors.

- Q: Are 101 aluminum sheets readily available in the market?

- Yes, 101 aluminum sheets are readily available in the market.

- Q: Can aluminum sheets be anodized with custom colors?

- Yes, aluminum sheets can be anodized with custom colors. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum, and during this process, dyes can be applied to achieve a wide range of custom colors.

- Q: What's the standard thickness of aluminum sheet?

- the thickness of tobacco aluminum foil and red wine bottle cap is designed according to customers demands and manufacturer has no stated specification.

- Q: This question asks about the effects of using aluminum sheets in the construction industry on the environment.

- <p>The environmental impacts of using aluminum sheets in construction are multifaceted. On the positive side, aluminum is lightweight, which reduces energy consumption during transportation. It is also recyclable, with a high percentage of construction aluminum being recycled, reducing waste. However, the production of aluminum is energy-intensive, contributing to greenhouse gas emissions. Additionally, mining for bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. Despite these concerns, aluminum's durability and resistance to corrosion can extend the lifespan of buildings, reducing the need for frequent replacements and thus the overall environmental footprint over time.</p>

- Q: Can aluminum sheets be used for honeycomb panels?

- Yes, aluminum sheets can be used for honeycomb panels. Honeycomb panels are typically made by bonding two thin sheets of material, such as aluminum, to a honeycomb core material. Aluminum sheets are commonly used for their lightweight and high strength properties, making them an ideal choice for honeycomb panel construction. The honeycomb structure provides excellent strength-to-weight ratio, making the panels suitable for various applications, including aerospace, automotive, construction, and furniture industries. The aluminum sheets offer durability, corrosion resistance, and ease of fabrication, making them a popular choice for honeycomb panels.

Send your message to us

Aluminum Sheets for Sale Buffalo NY - Aluminium Coil for Air Conditioning Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords