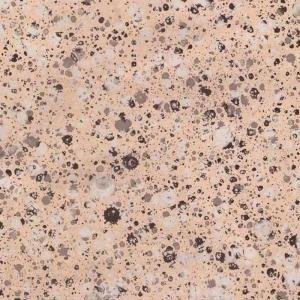

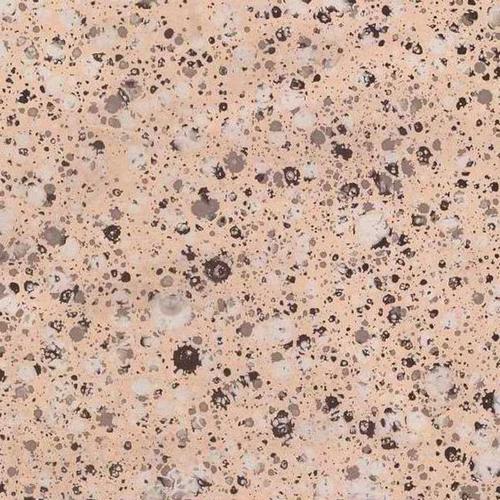

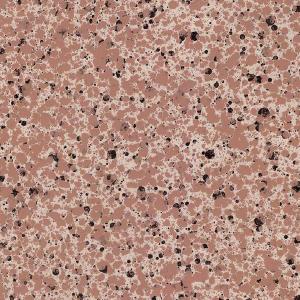

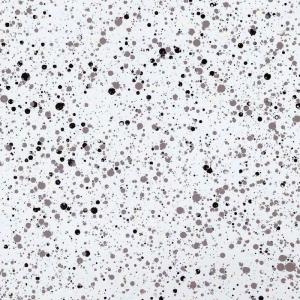

024 Aluminum Coil with Marble Grain Coating

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated sheetand coil choose aluminium sheet coil as raw material, after de-ester, cleaning,passivation layer processing, and then painting on this basis, the paint areprovided by famous international companies like PPG and Valspar from UnitedStates or Becker from Sweden, represent the most advanced level in the world.After the test of exposure by natural light in Florida, the quality assurance is more than morethan 20 years. As poor performance of color coated steel corrosion, rust,yellow rust after a large amount of the deficiency of serious impact on thebuilding's overall appearance. However, because of the advantages of rawmaterials, Aluminium coated coil have a high strength, corrosion resistance,high weather resistance, can be used recycle, save energy and protect theenvironment and other characteristics. Not only have the same strength with colorcoated steel, but also overcome the shortage of color coated steel. So, the Aluminiumcoated coil has been widely used as roofing and ceiling decorative envelopesystem board in modern constructions like large factories, exhibition halls,stadiums, airports, train station hospital and so on. We can choose Aluminiumcoated coil in different thickness and color, by cutting, pressing, punching,bending and other follow-up molding process for large span, the larger theoverall roofing, wall decorative panels used in construction; or cut them intosmall panels by bending, stamping mold or other processing for indoordecorative roofing plate; we can also composite them with polyurethane foam oraluminium honeycomb for energy-saving decorative wall plates.

Alloy | 1050,1060,1100,3003,3004,3005,3104,3105,5052,5005,8011 |

Temper | O,H42,H44,H46,H48 |

Thickness (mm) | 0.25mm-1.5mm for aluminium coated coil; 1.50mm-4.0mm for aluminium coated sheet. |

Width (mm) | 100mm to 2000mm |

Length (mm) | 800mm to 6000mm for sheet |

- Q: Can aluminum coils be used for electrical transmission lines?

- Yes, aluminum coils can be used for electrical transmission lines.

- Q: What is the composition of aluminum coils?

- Aluminum coils are typically composed of pure aluminum or an aluminum alloy. Pure aluminum coils consist of 99.5% aluminum, with trace amounts of other elements. Aluminum alloys, on the other hand, are made by combining aluminum with other metals such as copper, magnesium, manganese, or zinc. These alloys are specifically designed to enhance the strength, corrosion resistance, and other desired properties of the aluminum coils. The exact composition of aluminum coils may vary depending on the specific application and requirements, but they generally contain a high percentage of aluminum along with small quantities of other elements to create a more durable and efficient product.

- Q: This question seeks to understand the various types of aluminum coils that are commonly found in the market.

- <p>Aluminum coils available on the market today can be categorized based on their properties and applications. These include: 1. Plain Aluminum Coils: Used for general purposes like packaging and construction. 2. Embossed Aluminum Coils: Feature a textured surface, used in decorative applications. 3. Alloy Aluminum Coils: Made from a mixture of aluminum and other metals for enhanced strength or corrosion resistance. 4. Color Coated Aluminum Coils: Coated with paint or plastic for aesthetic or protective purposes. 5. Heat Treated Aluminum Coils: Processed to improve their mechanical properties. 6. Mirror Finish Aluminum Coils: Have a highly reflective, polished surface. 7. Pre-painted Aluminum Coils: Coated with a layer of paint before being used in construction or other applications. Each type serves specific industries and applications, with variations in thickness, width, and alloy composition.</p>

- Q: Are aluminum coils resistant to mold and mildew?

- Yes, aluminum coils are highly resistant to mold and mildew. Aluminum does not provide a favorable environment for mold or mildew growth, making it an excellent choice for applications where moisture and humidity are concerns.

- Q: How long do aluminum coils last?

- The lifespan of aluminum coils can vary depending on various factors such as maintenance, usage, and environmental conditions. On average, well-maintained aluminum coils can last between 15 to 20 years. However, with proper care and regular cleaning, some aluminum coils have been known to last even longer, up to 30 years or more. It is important to note that regular maintenance, such as cleaning the coils, checking for any damage or corrosion, and ensuring proper airflow, can significantly extend the lifespan of aluminum coils. Additionally, factors like exposure to harsh weather conditions, humidity levels, and the quality of installation can also impact the longevity of aluminum coils.

- Q: helicopters rotorblades are made of honeycombed aluminum to give them strength, so isn't it a good idea for automakers to use the same technology to strengthen the frames of autos to make them lesslikely to cave in during a side impact auto accident?

- Honeycombed materials are not strong in all directions. Honeycombed materials are strong in a force at 0 degrees, but will collapse under a teensy force at 90 degrees. Since a car can be damaged from many directions, the use of honeycombed materials would not be ideal. The website I've listed is about the strength of honeycombed materials and is interesting, but does not specifically address your question.

- Q: Can aluminum coils be used for electrical applications?

- Yes, aluminum coils can be used for electrical applications. Aluminum is a highly conductive material and is commonly used in various electrical applications such as transformers, motors, and generators. It offers advantages such as lightweight, good thermal conductivity, and cost-effectiveness, making it a suitable choice for electrical coils.

- Q: Can aluminum coils be used in food packaging?

- Yes, aluminum coils can be used in food packaging. Aluminum is a popular choice for food packaging due to its excellent barrier properties, lightweight nature, and ability to maintain the freshness and quality of food products. It is widely used in various forms, including coils, for packaging food items like beverages, snacks, and canned goods.

- Q: How are aluminum coils protected against moisture during storage?

- Various methods and materials are typically employed to safeguard aluminum coils against moisture during storage. One commonly utilized technique involves the application of a protective coating, such as a thin layer of oil or a corrosion-resistant film, which establishes a barrier between the coil and any moisture present in the surroundings. This coating effectively prevents direct contact between the aluminum surface and water, thereby minimizing the likelihood of corrosion or other forms of moisture-induced harm. In addition to protective coatings, it is possible to store aluminum coils in a controlled environment with low humidity levels. This can be accomplished by placing the coils in a dry warehouse or utilizing dehumidifiers to eliminate excess moisture from the storage area. By regulating the humidity, the probability of moisture condensation on the coils is diminished, affording them further protection against potential damage. Moreover, appropriate packaging plays a vital role in shielding aluminum coils from moisture during storage. Frequently, the coils are enveloped in moisture-resistant materials, such as plastic or moisture-proof paper, which create a barrier to prevent moisture from reaching the coils. Additionally, the packaging is often sealed to establish an airtight environment, thereby minimizing the chances of moisture infiltration. Regular inspection and maintenance are also crucial to ensure the ongoing protection of aluminum coils during storage. This entails examining the integrity of the protective coatings, monitoring the storage environment for any fluctuations in humidity levels, and promptly addressing any indications of moisture damage. On the whole, the utilization of protective coatings, controlled storage environments, appropriate packaging, and regular maintenance are key elements in safeguarding aluminum coils against moisture during storage. By implementing these measures, the risk of moisture-related damage is significantly reduced, ensuring the coils' quality and integrity until they are ready for utilization.

- Q: What are the applications of aluminum coils?

- Due to their unique properties and versatility, aluminum coils find wide-ranging applications in various industries. The construction industry is one major field where these coils are extensively used. They are lightweight, durable, and resistant to corrosion, making them suitable for roofing, siding, and insulation purposes. Additionally, aluminum coils are commonly employed in the production of gutters, downspouts, and ventilation systems for buildings. In the automotive sector, aluminum coils are utilized for manufacturing different components like heat shields, radiators, and condensers. The lightweight nature of aluminum makes it an ideal choice for enhancing fuel efficiency and reducing the overall weight of vehicles. Moreover, aluminum coils are employed in the production of heat exchangers and air conditioning systems in automobiles. The packaging industry also heavily relies on aluminum coils. They are commonly used to manufacture beverage cans, food containers, and packaging materials. Aluminum's high ductility and excellent formability make it a preferred material for producing these products. Additionally, aluminum coils act as a barrier against moisture, light, and oxygen, ensuring the preservation and protection of the packaged contents. In the electrical and electronics industry, aluminum coils find a crucial application. They are utilized in the production of transformers, power distribution systems, and electrical conductors. The high electrical conductivity and low density of aluminum make it advantageous for these purposes. Furthermore, aluminum coils are employed in the manufacturing of appliances such as refrigerators, air conditioners, and washing machines. They are also utilized in the production of furniture, decorative items, and various consumer goods. In conclusion, aluminum coils have vast and diverse applications in industries ranging from construction and automotive to packaging, electrical, and consumer goods. The combination of lightweight, durability, corrosion resistance, and excellent formability make aluminum coils an indispensable material in numerous sectors.

Send your message to us

024 Aluminum Coil with Marble Grain Coating

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords