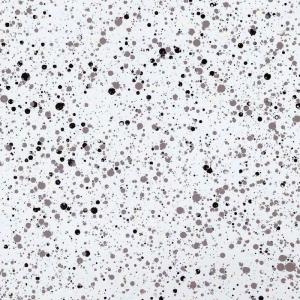

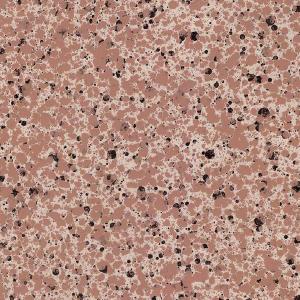

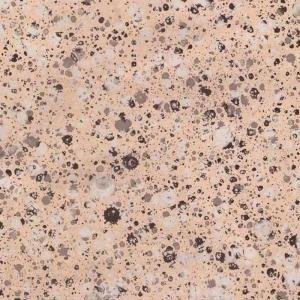

Royal Brown Marble Grain Aluminum Coil

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated sheetand coil choose aluminium sheet coil as raw material, after de-ester, cleaning,passivation layer processing, and then painting on this basis, the paint areprovided by famous international companies like PPG and Valspar from UnitedStates or Becker from Sweden, represent the most advanced level in the world.After the test of exposure by natural light in Florida, the quality assurance is more than morethan 20 years. As poor performance of color coated steel corrosion, rust,yellow rust after a large amount of the deficiency of serious impact on thebuilding's overall appearance. However, because of the advantages of rawmaterials, Aluminium coated coil have a high strength, corrosion resistance,high weather resistance, can be used recycle, save energy and protect theenvironment and other characteristics. Not only have the same strength with colorcoated steel, but also overcome the shortage of color coated steel. So, the Aluminiumcoated coil has been widely used as roofing and ceiling decorative envelopesystem board in modern constructions like large factories, exhibition halls,stadiums, airports, train station hospital and so on. We can choose Aluminiumcoated coil in different thickness and color, by cutting, pressing, punching,bending and other follow-up molding process for large span, the larger theoverall roofing, wall decorative panels used in construction; or cut them intosmall panels by bending, stamping mold or other processing for indoordecorative roofing plate; we can also composite them with polyurethane foam oraluminium honeycomb for energy-saving decorative wall plates.

Alloy | 1050,1060,1100,3003,3004,3005,3104,3105,5052,5005,8011 |

Temper | O,H42,H44,H46,H48 |

Thickness (mm) | 0.25mm-1.5mm for aluminium coated coil; 1.50mm-4.0mm for aluminium coated sheet. |

Width (mm) | 100mm to 2000mm |

Length (mm) | 800mm to 6000mm for sheet |

- Q: What is the electrical conductivity of aluminum coils?

- The electrical conductivity of aluminum coils is very high, making aluminum an excellent choice for conducting electricity efficiently.

- Q: The question asks if magnetic induction can be used to inspect the quality of an aluminum coil.

- <p>No, you cannot use magnetic induction to inspect the quality of an aluminum coil. Magnetic induction is a method used to detect flaws or discontinuities in ferromagnetic materials, such as steel, by inducing eddy currents. Aluminum is not a ferromagnetic material, so it does not retain magnetism or support the formation of eddy currents in the same way. Instead, other non-destructive testing methods like ultrasonic testing or radiographic testing may be more appropriate for inspecting the quality of aluminum coils.</p>

- Q: What are the advantages of using aluminum coils over other materials?

- Some advantages of using aluminum coils over other materials include its lightweight nature, excellent thermal conductivity, corrosion resistance, and ease of fabrication. Additionally, aluminum coils offer good electrical conductivity, making them suitable for various applications in industries like automotive, construction, and aerospace.

- Q: How are aluminum coils cut and shaped?

- Various methods and tools are utilized to cut and shape aluminum coils, depending on the desired size and shape. Slitting, shearing, and laser cutting are the most commonly employed techniques. Slitting is the act of dividing a wide coil into narrower strips. This procedure entails passing the coil through a series of circular blades that make precise cuts along its length. Thin aluminum strips are typically produced using this method, which can then be further processed or utilized in various applications. Shearing is another popular approach for cutting aluminum coils. It involves the use of a machine with a moving blade to slice through the coil. By applying pressure to the coil, a clean and straight cut is achieved. Shearing is commonly employed for cutting thicker aluminum coils and is ideal for creating straight cuts without deformations. Laser cutting is a more advanced technique used to cut and shape aluminum coils. It employs a high-powered laser beam to either melt or vaporize the metal along a predetermined path. This method offers exceptional precision and enables the creation of complex shapes and designs on the aluminum. Laser cutting is widely used in industries that require intricate and detailed cuts. Following the cutting process, various methods such as bending, rolling, stamping, or forming can be employed to further shape the aluminum coils. These techniques allow for the creation of different geometries and forms based on the specific requirements of the intended application. Overall, the cutting and shaping of aluminum coils involve a variety of techniques and tools, each suitable for different requirements. The choice of method depends on factors such as the coil's thickness, desired shape, and the level of precision necessary for the final product.

- Q: Is it safe or advisable to use aluminum coil for wrapping food?

- <p>Using aluminum coil to wrap food is not recommended. Aluminum can react with acidic or alkaline foods, potentially leaching harmful aluminum particles into the food. It's also not designed for food contact and may not be safe at high temperatures. Instead, use food-grade aluminum foil, which is specifically designed for cooking and wrapping food, ensuring it doesn't come into contact with non-food surfaces that could contaminate it.</p>

- Q: Can aluminum coils be used for automotive body panels?

- Certainly, automotive body panels can be made using aluminum coils. In fact, aluminum is gaining popularity in the automotive sector due to its numerous advantages. Its lightweight nature contributes to enhanced fuel efficiency and overall vehicle performance. Furthermore, aluminum exhibits exceptional resistance to corrosion, making it a durable option for automotive body panels. Additionally, aluminum can be easily shaped and molded, enabling intricate designs and improved aerodynamics. All in all, utilizing aluminum coils for automotive body panels presents a viable choice with a multitude of benefits.

- Q: What is the balanced chemical equation for aluminum and cobalt?That is all the information that the question gives. If you could help me out, I would really, really appreciate it.

- That's pretty sparse. Perhaps the question is referring to a single replacement reaction. Aluminum is above cobalt in the activity series, which allows us to predict that aluminum metal will reduce cobalt ions, while aluminum is oxidized. This occurs as long as there is an ion present which will react with the aluminum oxide layer on the surface of aluminum. This passivating Al2O3 layer keeps aluminum metal from reacting. The presence of chloride ions will break down the passivating layer allowing the aluminum metal below to react. Al2O3(s) + 6H+ + 8Cl- -- 2[AlCl4]- + 3H2O(l) 2Al(s) + 3Co2+ -- 2Al3+ + 3Co(s)

- Q: Can aluminum coils be used in the production of solar reflectors?

- Certainly! Solar reflectors can utilize aluminum coils in their production. Due to its exceptional reflectivity and durability, aluminum is widely employed in the manufacturing of these reflectors. The coils can be manipulated and molded into the desired shape for the reflector, facilitating efficient sunlight reflection onto the solar panels. Furthermore, aluminum's lightweight nature simplifies its handling and installation in solar reflector systems.

- Q: actually pollute more than the process of extracting it from earth and producing new aluminum?I saw a report about 5 years ago on this and was wondering if anyone else had info on this subject.

- There is a significant savings - especially in electricity - about 90% less energy used to recycle aluminum than it takes to smelt ore and process it into useable aluminum.

- Q: Can aluminum coils be used for solar panel applications?

- Yes, aluminum coils can be used for solar panel applications. They are often utilized as the base material for solar panels due to their lightweight, corrosion-resistant, and durable properties. Additionally, aluminum coils offer good thermal conductivity, enabling efficient heat dissipation in solar panels.

Send your message to us

Royal Brown Marble Grain Aluminum Coil

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords