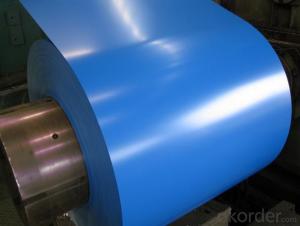

Alu-Zinc Galvalume Steel Coils/Plate SGCC Gi Dx51d

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Details

Basic Info.

Type:Steel Plate

Standard:ASTM, AISI, GB, JIS, DIN, BS

Certification:ISO, SGS, BV, RoHS, IBR

Surface Treatment:Galvalume

Technique:Hot Rolled & Cold Rolled

Application:Ship Plate, Boiler Plate, Container Plate, Flange Plate

Special Use:Carbon Steel

Stock:Not Stock

Thick:0.12-4.0mm

Width:600-1250mm

Zinc Coating:Az50-Az150G/M2

Material:Dx51d,Dx52D,G350-G550

Surface:Anti-Fingerprint,Minimumed Spangle ,Bright , Oiled

Export Markets:Global

Additional Info.

Trademark:Sino Steel

Packing:Properly Packed for Ocean Freight Exportation

Standard:SGS, ISO9001

Origin:Shandong

HS Code:721061000

Production Capacity:350000 Tons/Year.

Product Description

Hot Dipped 55% Aluminum Zinc Alloy Coated Steel by the Hot-Dip Process

Hot Dip Galvalume steel coil EN 10327 JIS G3321, ASTM A792M 55% AL-ZN coated

Specification:

| Commodity | AZ150 AFP G550 Galvalume steel coil with SGS certification |

| Technical Standard: | JIS,GB,DIN,BS,ASTM |

| Grade | DX51D / DX52D/ DX53D/G300/G550 |

| Types: | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.12-4mm |

| Type of coating: | aluminum-zinc alloy |

| Zinc coating | AZ50-AZ150 55% Al, 43.5%Zn, 1.5%Si. |

| Surface treatment | Pre-painted/ skin pass/ oiled/slightly oiled/unoiled/ dry/ anti-fingerprint/Non anti-fingerprint |

| Surface structure: | minimized spangle / regular spangle |

| ID coil | 508mm or 610mm |

| Coil weight | 3-8 MT per coil/ sheet will be cut as clients's requirments |

| Package: | Properly packed for ocean freight exportation in 20''containers |

| Application: | Industrial panels, roofing and siding for painting |

| Price terms | FOB,CFR,CIF,CNF,DAP,etc |

| Payment terms | 30%TT deposit in advance +70% TT balance against copy of B/L or irrevocable 70% L/C at sight |

| delivery time | Within 25 work days after deposit received. |

| Remarks | Insurance is all risks |

| MTC will be handed on with shipping documents | |

| Third party inspection such as SGS supported |

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: How are steel coils used in the production of electrical connectors?

- Steel coils are used in the production of electrical connectors as a primary material for manufacturing the connector's housing or casing. The steel coils are typically shaped, cut, and formed into the desired shape and size before being further processed and assembled with other components to create the final electrical connector product.

- Q: How do steel coils contribute to the construction sector?

- Steel coils contribute to the construction sector in several ways. Firstly, they are used to manufacture structural components such as beams, columns, and steel frames, which provide strength and support to buildings and infrastructure. Secondly, steel coils are used to produce reinforcement bars that are embedded in concrete, enhancing its tensile strength and durability. Additionally, steel coils are utilized in the construction of bridges, pipelines, and other large-scale projects that require robust and long-lasting materials. Overall, steel coils play a vital role in the construction sector by providing the necessary materials for sturdy and resilient structures.

- Q: im buying a sword and i dont know if i should buy a cold steel sword or a normal sword and that i can some how make that cold steel

- Cold Steel takes a billet (read piece of metal stock) in high carbon steel, usually 1060 which is pretty good, and then heats it up and pounds it into shape with a pre-made form. This is called forging. Their swords are not Folded (the traditional manner) they are Forged. This is different from taking a piece of 1060 steel and just grinding it down into shape. The forging process creates very strong steel (not as strong as folding) that is much stronger than a sword or knife made from grinding a piece of metal down into shape. Cold Steel's stuff is generally thicker, but they are practical and with enough practice you can wield it just like a thinner lighter sword. Their weapons are what you would call battle ready meaning you could feasibly take it into a sword fight and use it like its more traditionally crafted counter part. The only downfall is its weight and and the fact that it isn't as strong as a folded steel sword, but it would do very well.

- Q: How are steel coils used in the manufacturing of elevator components?

- Steel coils are used in the manufacturing of elevator components as they provide the necessary strength and durability required for various parts such as brackets, frames, and shafts. The coils are shaped, cut, and welded to create the desired elevator components, ensuring a sturdy and reliable structure that can withstand heavy loads and constant usage.

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- Definitely Steel Buildings and other prefab buildings are really durable than other concrete structures. They are also weather resistant and I think your friend is making a wise decision of buying a steel house... Also, these are usually cheaper than other buildings.

- Q: As we all know Shaq killed the movie Steel by suckin so bad but does anyone know what happened to the comic book version.

- Was cancelled after the 25th issue or so....the movie probably killed the comic too!

- Q: How do steel coils contribute to the packaging industry?

- Steel coils are indispensable in the packaging industry because they offer a strong and flexible material for packaging various products. Using steel coils in packaging guarantees the protection and preservation of goods during transportation and storage. The strength and durability of steel coils are essential contributions to the packaging industry. Steel is well-known for its high strength-to-weight ratio, making it ideal for packaging heavy and bulky items. Steel coils can endure significant pressure and impact, ensuring that goods remain intact and undamaged throughout the supply chain. This strength also allows for packages to be stacked, optimizing storage space and minimizing the risk of damage. Moreover, steel coils are highly resistant to corrosion and moisture. This property is especially crucial in the packaging industry as it helps safeguard goods from environmental factors that could potentially compromise their quality. Steel coils can be coated or treated to enhance their corrosion resistance, ensuring that packaged products remain in excellent condition. Furthermore, steel coils are versatile and can be easily customized to meet specific packaging requirements. They can be cut and shaped into various forms, such as sheets, straps, or bands, to secure and protect different types of products. Additionally, steel coils can be seamlessly integrated with other packaging materials, like cardboard or plastic, to provide added strength and stability. Another advantage of steel coils in the packaging industry is their recyclability. Steel is one of the most widely recycled materials globally, and steel coils can be easily recycled and reused. This aspect of sustainability makes steel coils an environmentally friendly choice for packaging, contributing to waste reduction and resource conservation. To summarize, steel coils play a crucial role in the packaging industry by offering strength, durability, corrosion resistance, versatility, and recyclability. Their utilization ensures the secure transportation and storage of goods, providing a dependable and sustainable packaging solution for various industries.

- Q: Steel is strong in both tension and compression. Concrete is only strong in compression, and is very fragile in tension. Plus, concrete is heavy--a huge drawback in, say, a bridge deck. And its fairly expensive. And it hides the condition of the steel embedded within it. So what does it bring to the table? Why use it at all?

- As a composite material, reinforced concrete can be an economical alternative to structural steel in building, bridge and other superstructures. Reinforced concrete can be formed into almost any shape in the field. The bulk of reinforced concrete material - the aggregates - can often be produced local to a project, reducing manufacturing cost. Reinforced concrete weight can be a benefit, resisting loads that cause displacement, uplift and overturning.

- Q: What is the use for spring steel that take advantage of its unique properties?

- The primary use is for springs. It can be deflected to a large extent by applying a force it will return to its original shape when the force is removed. The force/displacement relationship tends to be a constant. A lesser use is to use spring steel wire as a vibrating string on a stringed instrument.

- Q: No. Not Stainless steel, I mean STEEL.Not a specific type, but STEEL.Thanks. xo

- This Site Might Help You. RE: Is Steel a Pure Substance or a Mixture? No. Not Stainless steel, I mean STEEL. Not a specific type, but STEEL. Thanks. xo

Send your message to us

Alu-Zinc Galvalume Steel Coils/Plate SGCC Gi Dx51d

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords