Aluminum Alu Product for Figure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

- Q: I've been collecting old a/c's and was wondering if it's either worth taking the copper tubes out or just take the aluminum and copper to the recycling centerBtw I'm doing this for money.

- If you are doing it for money, then your labor is free, and the profits are 100%The recycle center won't want the job of separating the copper from the other metals, so they will decline any waySo get startedAnd turn in just the copper, and just the aluminum if you want the money.

- Q: which percentage of waste is recycled in the USA per year?

- Today, this country recycles 28 percent of its waste, a rate that has almost doubled during the past 15 yearsWhile recycling has grown in general, recycling of specific materials has grown even more drastically: 42 percent of all paper, 40 percent of all plastic soft drink bottles, 55 percent of all aluminum beer and soft drink cans, 57 percent of all steel packaging, and 52 percent of all major appliances are now recycledTwenty years ago, only one curbside recycling program existed in the United States, which collected several materials at the curb.

- Q: i stole about 1000 dollars worth of aluminum tubing and got charged with 2 feloniesTheft 1 for stealing the and criminal mischief for cutting the tubes into peicesIm only 18 and i have a clean recordi go to court in a few weeks and was wondering if it is possible to plead down the felonies to misdemeners? and also do you think i will have to go to jail? for how long? what will the punishments be? thankyou

- The buoyant force is equal to the weight of the water displacedIn other words, however much 550 pennies weighs, you have to displace that weight of water with your boatYour goal should be to try to fashion as large a hull as possible under water, and then find a place to put the pennies.

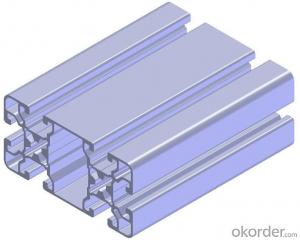

- Q: What is the HS code for aluminum profile?

- What type of aluminum? Fluorocarbon polymer sprayed aluminum profile HS Code: 7606 anodized aluminum profile, custom HS code 7604, the total is unclear

- Q: So, I'm kind of confused in chemistry.Can someone name some normal, everyday things that areelementscompoundsand mixturesI get them mixed up!

- Make Over 200 Juicy, Mouth-Watering Paleo Recipes You've NEVER Seen or Tasted Before?

- Q: I just bought Better N EggI want to make meatloaf but they tell me that you need the yolk for the meat to bindWill the whites work?

- Mini Turkey Meatloaves Preparation Time: 20 minutes Baking Time: 40 minutes Serves: 6 Ingredients: Meatloaves Ingredients: 20 ounces (1 package) lean ground turkey 2/3 cup ground seasoned bread crumbs 1/2 cup finely chopped onion 1/3 cup finely chopped celery 1/4 cup Better'n Eggs? 1 tablespoon chopped parsley 1 teaspoon ground mustard 1/2 teaspoon salt 1/3 cup ketchup Glaze Ingredients: 2 tablespoons ketchup 1 tablespoon brown sugar 1/2 teaspoon ground mustard Better'n Eggs Instructions: 1Heat oven to 350° FIn medium bowl combine all meatloaf ingredients; mix well, using hands if necessaryForm into 6 (4x2 inch) loavesPlace on aluminum foil lined 15x10x1-inch baking pan 2In small bowl combine all glaze ingredients; mix wellSpread glaze over top of each loafBake for 35 to 40 minutes or until no longer pink Nutritional Facts: 1 serving, Calories: 224, Fat: 6 g, Cholesterol: 63 mg, Sodium: 572 mg, Carbohydrate: 17 g, Dietary Fiber: 1 g, Protein: 24 g

- Q: Where can we get Coca-Cola Blāk? I heard the French version has more coffee flavor

- EZ means EASY My company called EZ tube display as EXhiliteExhilite is a light-weight aluminum tube frame systemIt offers a complete line of trade show display with numerous design modelsWe provide configuration flexibility with multifaceted components which facilitate different combinations and for future expansionWashable tension fabrics pillowcase graphics slip over the frame structure to express a perfect display in trade-showExhilite is our Flag-ship product which will be adapted in our global chain-service in trade-show businessExhilite also provide custom-made display system to suite your needsWe have imported 3-D bending machine and high precision digital printer -(Dgen from Korea) supported by our highly-creative design team which will be a perfect match to your design expectationWe also provide installation and dismantling service in exhibition and trade-show.

- Q: So our puppy got into the trash can while I was in the shower and ate some aluminum foil. Will it affect her and what may happen? What can I do? She seems ok, a little whiney, and poppin' a little more than usual. I wasn't able to get her into the vet until later this afternoon and am worrying about it, so I thought I'd ask.

- I think she would be fine. When she goes potty or poops somewhere look for blood and keep an eye on her!

- Q: I've always been curious.You can cook something on aluminum foil in an oven, and then you can touch the foil right after taking it out of the oven and it's not even hot, not even a little bit.Why is this?Thanks!

- Your fingers can drain away the small amount of heat within thin aluminum without getting burned but can not drain off enough heat from the baking pan to drop its temperature and avoid a burnYour finger and the aluminum will try to come to the same temperature when you touch the aluminum, but your finger will win.

Send your message to us

Aluminum Alu Product for Figure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches