Al-Zinc Coated steel Rolled coil for roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

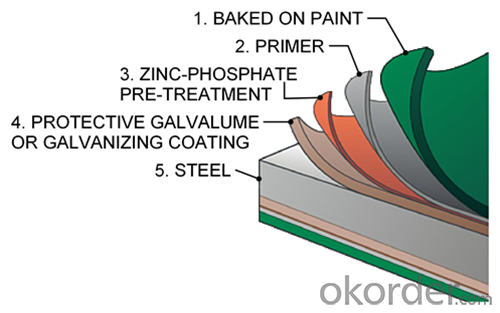

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of steel coil cutting processes?

- There are several different types of steel coil cutting processes, including shearing, slitting, and laser cutting.

- Q: What is the tensile strength of steel coils?

- The tensile strength of steel coils varies depending on the specific grade and composition of the steel. However, on average, steel coils have a tensile strength ranging from 400 to 600 megapascals (MPa).

- Q: Many gerber knives are made out of what gerber calls high Carbon steels and I was wondering if anyone knew exactly what is this mysterious steel.

- Carbon, when added to steel increases the hardness of the metal. The higher the carbon content the harder(pure carbon = diamond) the blade will be and the longer it will hold its sharpened edge. Too much carbon however can make it too brittle to use as a blade. iron, carbon and chromium(for the stainless in stainless steel) mixed in the right portion makes a high carbon stainless steel knife. All of which is kinda pointless if the blade is not forged correctly.

- Q: What are the factors driving the growth of the steel coil industry?

- There are several factors driving the growth of the steel coil industry. Firstly, the increasing demand for steel products across various sectors such as construction, automotive, and infrastructure is contributing to the growth of the industry. Steel coils are widely used in these sectors for manufacturing various products such as automobiles, buildings, bridges, and pipelines. Secondly, rapid industrialization and urbanization in emerging economies are fueling the growth of the steel coil industry. Countries like China, India, and Brazil are witnessing significant infrastructure development and construction activities, which require a large amount of steel coils for various applications. Additionally, technological advancements in the manufacturing process and the use of advanced steel alloys are driving the growth of the industry. These advancements have led to the production of high-quality steel coils that offer better strength, durability, and corrosion resistance. Moreover, the growing focus on sustainable and eco-friendly practices is also driving the growth of the steel coil industry. Steel is a highly recyclable material, and the increasing awareness about the environmental benefits of using steel is boosting its demand. Furthermore, favorable government policies and initiatives to promote domestic steel production and reduce imports are also contributing to the growth of the industry. Governments are implementing measures such as import tariffs and subsidies to support local steel manufacturers, which is driving the demand for steel coils. In conclusion, the factors driving the growth of the steel coil industry include increasing demand from various sectors, rapid industrialization, technological advancements, environmental awareness, and supportive government policies.

- Q: What kind of steel should be used for constructing a steel building?

- Quality okorder /

- Q: How does the surface finish of steel coils affect their performance?

- The surface finish of steel coils plays a significant role in determining their performance. A smooth and uniform surface finish enhances the coil's ability to resist corrosion, improves its aesthetic appeal, and allows for easier cleaning and maintenance. It also facilitates better adhesion of coatings or finishes, which can enhance the coil's durability and protect it from environmental factors. On the other hand, a rough or uneven surface finish may compromise the coil's performance by promoting corrosion, reducing its ability to withstand wear and tear, and potentially impairing its functionality in certain applications. Therefore, the surface finish of steel coils is a critical factor that directly impacts their overall performance and longevity.

- Q: How can steel coils be recycled?

- Steel coils can be recycled by first removing any contaminants or coatings from the surface. The coils are then shredded into smaller pieces and melted in a furnace. The molten steel is then formed into new coils or other steel products.

- Q: What are the different types of steel coil cutting blades?

- Various types of steel coil cutting blades exist, each specifically designed for particular cutting purposes. 1. Slitting Blades: These blades are utilized to cut steel coils into narrow strips. They possess a straight cutting edge and come in different widths to accommodate various slitting needs. Industries like automotive, construction, and metal fabrication commonly employ these blades. 2. Shearing Blades: These blades are created to cut steel coils into flat sheets. They feature a curved cutting edge that enables a clean and precise cut. Steel service centers, where large coils are transformed into flat sheets for further manufacturing processes, frequently utilize shearing blades. 3. Circular Blades: Also known as rotary blades, these blades are employed for continuous cutting of steel coils. With a circular shape adorned with sharp teeth along the edge, they can effectively cut through the coil as it passes through the cutting machine. Industries such as packaging, printing, and paper manufacturing often make use of circular blades. 4. Guillotine Blades: These blades are employed to cut steel coils in a straight downward motion. Possessing a vertically moving straight cutting edge, they can effectively slice through the coil. Guillotine blades are frequently used in heavy-duty cutting applications that involve thick steel coils or large quantities of material. 5. Slitter Knives: Similar to slitting blades, slitter knives are typically smaller and employed in slitting machines that require multiple blades. Industries requiring high-precision slitting, such as electrical transformer production or precision metal stamping, often rely on slitter knives. Each type of steel coil cutting blade possesses unique characteristics and designs that render them suitable for specific cutting tasks. The appropriate blade selection depends on factors like steel coil thickness and width, desired cut quality, and specific application requirements.

- Q: engineering sloutions related to steel fabrication

- not okorder /

- Q: What are the main properties of steel coils?

- The main properties of steel coils include high strength, durability, resistance to corrosion, and the ability to be shaped and formed into various sizes and dimensions. Steel coils are also known for their excellent heat and electrical conductivity, making them suitable for various industrial applications.

Send your message to us

Al-Zinc Coated steel Rolled coil for roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords