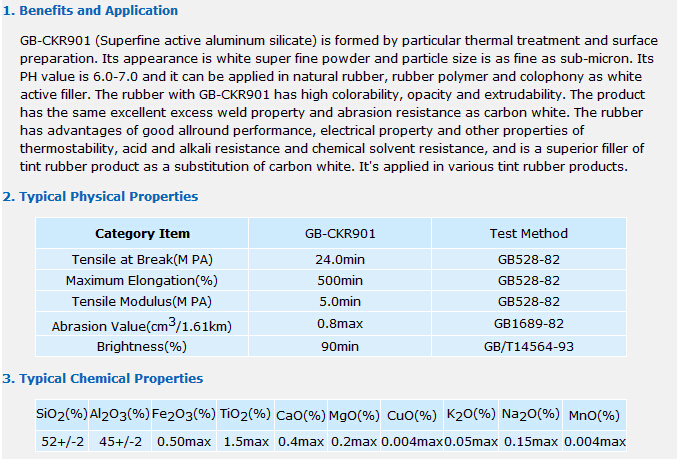

ACTIVE ALUMINA SILICATE IN RUBBER (GB-CKR901)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

4.Application

4.Application

- Q: Are there any differences between bentonite and kaolin?

- Bentonite (Bentonite) predominantly montmorillonite aqueous clay minerals. The chemical composition of montmorillonite: (Al2, Mg3) Si4O10 OH2 nH2O, because it has special properties such as swelling, adhesion, adsorption, catalysis, thixotropy, suspension and cation exchange. So widely used in various industrial fields.

- Q: What are the surface modification technologies of calcined kaolin and the matters needing attention?

- Calcined kaolin is a kind of mineral material with high whiteness, large specific surface area, good insulation and good thermal stability, which is calcined, dehydrated and removed volatile substances. Calcined kaolin has excellent chemical corrosion resistance, solvent resistance, acid and alkali resistance and good reinforcing and processing performance, widely used in paints, coatings, paper, rubber and plastic products, cable, ceramics and other industries.

- Q: What is the difference between diatomite and kaolin? Thank you

- The special porous structure of natural diatomite can be observed under microscope, and the microstructure of diatomite is the characteristic of physical and chemical properties of diatomite.

- Q: How to remove iron impurities in kaolin and increase their whiteness

- The types of pigment ions are different, and the reagents and methods used are different:1, the surface of the adsorbed kaolinite is Fe3+, that is, when iron exists in the form of Fe2O3, the reaction of Fe3+ with Na2S2O4 is reduced to two valent iron salt, which is removed by rinsing and filtering;2, when the adsorption ion is Fe2+, that is iron in the form of FeS2, the oxidant should be used and its reaction, the oxidation of soluble ferrous sulfate and ferric sulfate, so that it can be washed away colorless oxides;3, the majority of samples containing both Fe3+ and Fe2+, the oxidation reduction combined bleaching method, first with the oxidant and reducing agent will become Fe2+ Fe3+ its reduction to Fe2+. Removed by rinsing, filtering, etc.

- Q: The building is kaolin. Does it have radiation? District 15 years ago is a kaolin processing plant, there will be residual radiation it?

- The first thing to stress is that the world is full of radiation, whether it's land, sea, mountains, fields, rocks, soil...... We call it the background radiation intensity".

- Q: The cosmetic effect of kaolin?

- Kaolin is a nonmetal mineral, good quality products for whiteness high component, high temperature resistant, soft texture, good acid and alkali resistance, no stimulation to the skin, and has certain adsorption ability, remove skin dirt, grease on the skin absorption and waste etc..

- Q: What is kaolin?

- 1. brightness and brightnessWhiteness is one of the main parameters of kaolin's technological properties. Kaolin with high purity is white. For ceramic raw materials, the whiteness is more important after calcination. The higher the whiteness of calcination, the better the quality

- Q: High silica can be converted into kaolin? Add or remove some of the substances, specific operations! Thank you

- In the 50% general and kaolin silica, and alumina was the main component, Magnesium Oxide, iron, sodium, calcium, potassium and other small, therefore, the two components have significant differences, its essence is far different. Rely on laboratory reagents to add remove some substances is almost impossible to get into high silica kaolin

- Q: Kaolin with magnetic separator, how about iron?

- Kaolin separator iron removal process is dry and wet dressing process method for magnetic separation of magnetite, in iron removal process, it can improve the reuse rate in the process of iron removal process, less water consumption, save water, reduce production costs, reduce pollution, dust and dust removal device with special magnetic separation, not air pollution is a kind of high production efficiency, good product quality, no environmental pollution process of creative.

- Q: How are laterite and kaolin weathering crusts formed respectively?

- This soil layer contains very little nutrients, mainly the B layer. (soil profiles can be found)The reason for red clay is that it is red when it is trivalentHow is kaolin formed?Kaolin is a mainly composed of kaolin clay. After fully weathered feldspar, kaolin, quartz and generate soluble salts; then with the rain, the river rafting on it and then re deposition, quartz and soluble salts have been separated, can be accounted for in kaolin kaolin. The largest porcelain is. Good raw material for the production of porcelain.

Send your message to us

ACTIVE ALUMINA SILICATE IN RUBBER (GB-CKR901)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches