Grainger Aluminum Plate

Grainger Aluminum Plate Related Searches

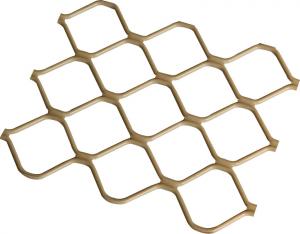

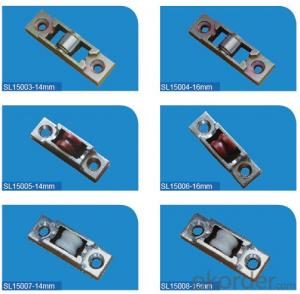

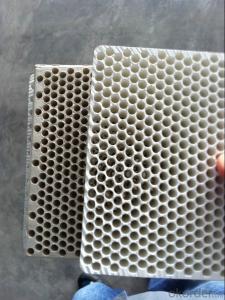

Aluminum Cooking Plate Aluminum Grill Plate Aluminum Grid Plate Aluminum Spinning Plate Drill Aluminum Plate Aluminum Tooling Plate Aluminum Gland Plate Aluminum Floor Plate Grooved Aluminum Plate Aluminum Triangle Plate Aluminum Mounting Plate Aluminum Joining Plate Aluminum Thawing Plate Aluminum Plenum Plate Aluminum Vin Plate Ground Aluminum Plate Aluminum Paper Plate Gold Plate Aluminum Kaiser Aluminum Plate Aluminum Metal Plate Aluminum Surface Plate Aluminum Profile Plate Aluminum Cooling Plate Drilled Aluminum Plate Polished Aluminum Plate Avenger Aluminum Plate Aluminum Serving Platters Finned Aluminum Plate Aluminum Heater Plate Aluminum Flat PlateGrainger Aluminum Plate Supplier & Manufacturer from China

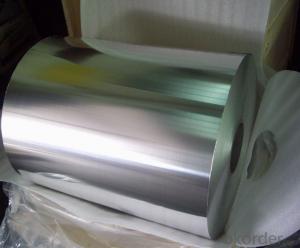

Grainger Aluminum Plate is a versatile material known for its strength, lightweight properties, and corrosion resistance. It is widely used in various industries for manufacturing components and structures that require these characteristics. The aluminum plate is available in different grades, thicknesses, and sizes to cater to the diverse needs of customers. This product is highly sought after for its ability to withstand harsh environmental conditions and maintain its integrity over time.The Grainger Aluminum Plate is commonly used in applications such as construction, aerospace, automotive, and marine industries. Its lightweight nature makes it an ideal choice for reducing the overall weight of structures and vehicles, while its strength ensures durability and longevity. Additionally, its corrosion resistance makes it suitable for applications where the material may be exposed to moisture or other corrosive elements. This versatility makes the Grainger Aluminum Plate a popular choice among engineers and designers looking for a reliable and high-performance material.

Okorder.com is a leading wholesale supplier of Grainger Aluminum Plate, offering a vast inventory of this product to cater to the needs of various industries. As a reputable supplier, Okorder.com ensures that the aluminum plates are of the highest quality and meet the specific requirements of their customers. With a commitment to customer satisfaction, Okorder.com provides competitive pricing and efficient shipping options to make the procurement process as seamless as possible. This makes Okorder.com a reliable choice for businesses looking to source high-quality Grainger Aluminum Plate for their projects.

Hot Products