Raw Materials for Refractory:76% Rotary/Shaft/Round Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

76% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Raw Material for Refractory

Introduction

Calcined bauxite is one of the principal ore of aluminum. Calcined bauxite contains hydrous aluminum oxides and aluminum hydroxides, formed through the laterization of aluminous rocks in tropical and subtropical areas .calcined bauxite is obtained by calcining (heating)superior grade bauxite at high temperature (from 85OC to 1600C) .this removes moisture thereby increasing the alumina content. compared to an alumina content of about 57%to 58%in raw bauxite, calcined bauxite has an alumina content of 84%to88%.the heating is carried out in rotary kilns

1.Applications

Raw bauxite is typically classified according to its intended commercial application,such as abrasive ,cement ,chemical, metallurgical, and refractory .as raw material for use in high alumina and super duty refractory bricks and shapes ,plastics ,castable refractory, motors, gun mixes, ramming mixes, abrasive grains and other products.

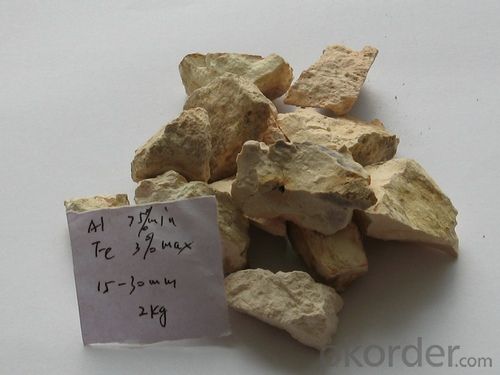

2.specifications

Item | Al2O3 | Fe2O3 | TiO2 | K2O+Na2O | CaO+MgO | Bulk density |

GAL65 | ≥65 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.6 |

GAL75 | ≥75 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.7 |

GAL80 | ≥80 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.8 |

GAL85 | ≥85 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.0 |

GAL86 | ≥86 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.1 |

GAL87 | ≥87 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.2 |

GAL88 | ≥88 | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

GAL90 | ≥90 | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

Calcined Bauxite Grade:

1.Refractory Grade: |

Refractory grade bauxite has high refractoriness, good mechanical strength and moderate slag resistance. Bauxite in the refractory industry is typically used in ladle working lining, tundish furniture, delta sections, general perpose repairment, aluminium melting furnace and mineral processing.

3. Rotary calcined bauxite: |

Rotary Kiln Bauxite, as the name suggests, it is the bauxite produced by rotary kiln. there are three kinds of kilns for bauxite production mainly, rotary kiln, shaft kiln and round kiln.

4. Shaft kiln calcined bauxite: |

Shaft kiln bauxite, the bauxite calcined by shaft kiln. the raw material-bauxite ore is loaded from the top of kiln together with coal powder and combustion improver,the fire of calcination comes from kiln bottom, about 1300-1400 ℃After the complete calcination, the bauxite is carried out from the bottom.

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What is the role of adding chromium oxide green in unshaped refractory materials

- Generally, less is added in corundum or corundum spinel refractory material, but it can significantly improve the material performance such as high temperature strength, erosion resistance, thermal and shock stability, etc.

- Q: For refractory, what is critical particle size? Thank you.

- Critical granularity means the maximum size of particles in refractory.

- Q: How can refractory materials be divided?

- There are many criteria for the classification of refractories.Just referring to a book about refractory.

- Q: How long can gypsum board endure fire?

- Fire endurance refers to the fire-resistent limit of the whole system of light-gauge steel structure coupled with gypsum. It does nor merely refers to gypsum board. Fire endurance of the common gypsum board with the thickness of 9.5mm keeps 1.5 hours. Those gypsum board with the thickness of 12mm has a fire endurance of 3 hours.

- Q: Is fireclay corrosive?

- No. All of the refractory materials have stable chemical properties and their usability can be guaranteed under high temperatures.

- Q: How to detect the acid resistance of refractory? Is there any standard? Thank you

- What material it is. There are many kinds of refractory materials, and I basically understand all petrochemical refractory.

- Q: Please answer the questions about the packing and transportation requirements of refractory materials.. Requirements for packing of refractory bricks

- Exports should be fumigated outside of South East asia. Pallet packing is the most common, convenient and inexpensive.

- Q: What's the material of electrical fire prevention board?

- Industrial electrical fire prevention board is mainly aimed at fire protection and thermal insulation. Iron plate is electrically conductive with good thermal conductivity, which will cause the result that the equipment is not insulated and suffers larger superheating surface! ! ! !

- Q: What is high alumina refractory?

- It refers to inorganic non-metallic material with refractoriness of higher than 1580℃. Refractoriness refers to the celsius temperature that the cone-shaped refractory sample without load can resist, and under which the sample won't soften and melt down. Refractory material appears together with high temperature technology, and roughly dates from the Middle Bronze age. In the Eastern Han Dynasty (AD25~AD220) of China, fireclay refractories has been used as furnace refractories and saggers for making porcelains. In the early 20th century, refractory material develops toward the direction of high purity, high dense and ultra high temperature products, and meanwhile unshaped refractory and refractory fiber with no need of firing at all and with low energy consumption appear.

- Q: How many grades of fire?rating are there for interior decoration materials?

- It can be divided into construction classification and fire resistance rating. Fire prevention for buildings. Fire prevention measures should be taken in the architectural design to prevent fires and reduce fire hazards to life and property. Building fire protection includes two aspects: fire prevention before fire disaster and measures in fire disaster, among which the former is mainly to confirm the fire resistant rating and fire-resistant structure.

Send your message to us

Raw Materials for Refractory:76% Rotary/Shaft/Round Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords