6000/6200/6300 series deep groove ball bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

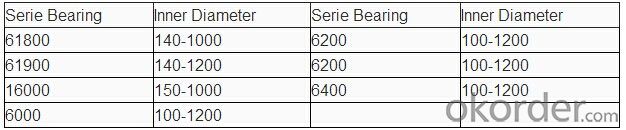

Specification

6000/6200/6300 series deep groove ball bearing

Specification:

Deep groove ball beaings composed of four basic parts: Inner ring, outer ring, ball and cage. In normal operation cases, inner raceway, outer raceway and ball mainly bear load, and the cage separate and maintain a stable effect for ball.

Product Application:

Deep groove ball bearings the most widely used in mechanical industry. Such as precision instruments, low noise electric motor, automobile, motorcycle, woodworking machinery, textile machinery transmission shaft, mining machinery, electromechanical equipment, plastic machinery, office equipment, medical equipment, fitness, national defense, aviation, aerospace and sports equipment and general machinery, etc.

| Name | Deep Groove Ball Bearing | ||||||||||||

| Type | Ball | ||||||||||||

| Materials | GCr15,Ceramic,Plastic,Chrome steel,stainless steel,carbon steel | ||||||||||||

| cage's material | Steel,Brass,Nylon,Iron, Copper | ||||||||||||

| Place of original | Shandong,China(Mainland) | ||||||||||||

| Seals type | Open,Sealed,ZZ,Z,2RS,RS | ||||||||||||

| Clearance | C0,C1,C2,C3,C4,C5,C6 | ||||||||||||

| Precision | ABEC-1 | ||||||||||||

| Feature | This is consisted of an inner and other ring with a cage containing a complement of precision balls. | ||||||||||||

| Main application | Automobile,electrical equipment,instruments,agriculture machinery and many kinds of special machinery. | ||||||||||||

| Brand | OEM,ODM | ||||||||||||

| Market | America,Middle East,Southeast Asia,Brazil | ||||||||||||

| Quality level | AA+,A,B,C | ||||||||||||

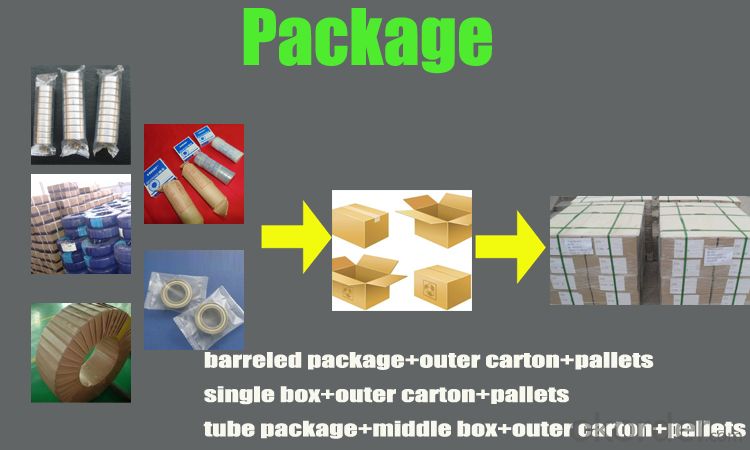

| Package | 1,barreled package+outer carton+pallets | ||||||||||||

| 2,single box+outer carton+pallets | |||||||||||||

| 3,tube package+middle box+outer carton+pallets | |||||||||||||

| 4,According to your requirement | |||||||||||||

| MOQ | 10PCS | ||||||||||||

| Port | Qingdao | ||||||||||||

| Payment Terms | T/T,PAYPAL,WESTERN UNION | ||||||||||||

| Delivery time | 5-25days,According to QTY | ||||||||||||

Package

Factory

- Q: Why is the rated speed of deep groove ball bearings (reference speed) greater than the limit speed, greater than almost double?. Only deep groove ball bearings are like this? Why?

- The maximum speed of various bearings can be checked by table, and the ultimate speed of deep groove ball bearings is very high. But, "why is the rated speed of deep groove ball bearings (reference speed) greater than the limit speed, greater than almost double?". Only deep groove ball bearings are like this?" Where does that come from? No, it will damage the bearings very soon.

- Q: What does "2RZ" mean in deep groove ball bearings 60000-2RZ?

- 2RZ stands for non-contact rubber dust cover

- Q: The deep groove ball bearing rubber ring is too thick. What's wrong with it?

- Deep groove ball bearing sealing ring in the case of increased thickness will increase torque, bearing feel bad, service life reduced. Generally non contact, light contact, standard contact! The specific thickness design shall be determined according to the dustproof groove of the ferrule, so as to achieve the desired effect

- Q: Deep groove ball bearings, iron cap seals and rubber cover seals are distinguished?

- Deep groove ball bearings, rubber cover for sealing rings, deep groove ball bearings, iron cover for dust cover, sealing ring than dust cover dust, good sealing; iron cover only dustproof, waterproof rubber cover, waterproof and dustproof.Also, tell me about the classification of rolling bearings. 1. contact seals: felt rings, oil seals, lip seals, seals. 2.: non contact seal oil seal gap seal, labyrinth seal

- Q: How can we split the deep groove ball bearings?

- The steel cage can be disassembled first.

- Q: Deep groove ball bearings, 37 diameter, 20 diameter, what type of bearings?

- It is estimated that the non-standard bearings6004 bearing outer diameter 426204, bearing outer diameter 476304, bearing outer diameter 52

- Q: I want the standard is best GB, and if other mechanical standards are also ok. 2, mainly to bearing diameter tolerance (preferably all grades have).

- Go online to search. You should be able to find what you need

- Q: Check the check manual, found strange, deep groove ball bearing dynamic load and static load is large, much largerBut the dynamic load of spherical roller bearing is much smaller than that of static load. The tall man knows, tell me to solve the puzzle!

- Rated dynamic load refers to the rated life of 1 million RPM bearings bear the load,Rated static load refers to the bearing load, the static load of the largest roller and raceway contact, permanent deformation and rolling body raceway and rolling body for the diameter of the 1/10000. Know the definition, your problem is not a problem.

- Q: Are deep groove ball bearings rolling bearings?

- The most obvious difference between them is that the rolling bearings have rolling bodies between the outer ring and the inner ring, but there is no between the inner and outer rings of the sliding bearings.

- Q: The difference between deep groove ball bearings and thrust ball bearings

- Thrust ball bearings can only withstand one-way axial loadDeep groove ball bearings are mainly subjected to radial loads and small axial loads at the same time...

Send your message to us

6000/6200/6300 series deep groove ball bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords