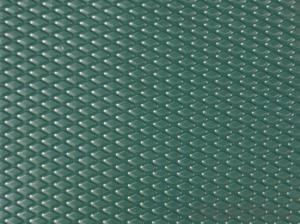

5mm Cost Price Alumet Baked Enamel Embossed Aluminum Alloy Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Company&Products Introducting

Established | 2012 years |

Product Type | Aluminium plate, Aluminium sheet, Aluminium coil, Aluminium strip.etc |

Product Martial | 1xxx series,3xxx series,5xxx series, 6xxx series,8xxx series |

Hardness state | HO,H14, H18, H24.etc |

Product Size | Thickness:0.1mm-10mm, 100mm<width<2000mm, Length :2000mm - 8000mm Also accept customized |

Surface Treatment | Mill finished |

Processed | Aluminium 5 bar, embossed plate, aluminium per-printed coil, aluminium tile,etc |

Min order quantity | 5 tons |

Short lead time | 15-20 days |

Application | Architectural/Decoration,Household,Transformer,Appliance,Transportation,Electrommunication,Food, etc |

Month Capacity | 5000 tons |

Accepted Payment Type | T/T,L/C |

Port of Loading | Shanghai |

Packing | Export wooden pallets. Customer's requests. |

Oversea Market | South America, Southeast Asia, Africa, Oceania, Mid East |

Ratio of Domestic/Export | 70%,30% |

Our advantage | Manufacture near from Shanghai reasonable price, various product, ensure quality |

Specifications:

1.Aluminum Sheet and Plate & Panel.

2.without oxidation and scratch.

3.Thickness:0.1mm-10mm

4.long-term of cooperation

5.the quality of the malitary level

- Q: Can aluminum sheet be used for aerospace structural components?

- Certainly, aerospace structural components can indeed utilize aluminum sheet. In the aerospace industry, aluminum is widely employed owing to its advantageous characteristics, including a high strength-to-weight ratio, resistance to corrosion, and excellent formability. By using aluminum sheet for these structural components, it becomes possible to construct aircraft that are lightweight, a crucial factor for optimizing fuel efficiency and performance. Moreover, aluminum is readily accessible and cost-effective, making it a favored option for aerospace applications. Nevertheless, it is worth mentioning that the selection of the aluminum sheet's specific grade and thickness will depend on the precise requirements and specifications of the aerospace structural component.

- Q: Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Indeed, aluminum sheets are well-suited for the production of electronic enclosures. The reason for aluminum's popularity in this regard lies in its remarkable combination of strength, durability, and lightness. Moreover, its capacity for conducting electricity effectively qualifies it for dissipating the heat generated by electronic components. Furthermore, aluminum sheets can be effortlessly molded, shaped, and machined to meet the precise specifications of electronic enclosures, thereby allowing for personalized and adaptable designs. Additionally, its ability to resist corrosion renders it suitable for safeguarding electronic devices against environmental elements. In summary, aluminum sheets offer the perfect material solution for the manufacturing of electronic enclosures.

- Q: This question asks for a comparison of the positive and negative aspects of utilizing aluminum sheets in various applications.

- <p>Advantages of using aluminum sheets include their lightweight nature, which reduces transportation and handling costs. They are also corrosion-resistant, making them suitable for outdoor applications. Aluminum sheets are recyclable and environmentally friendly, with a high recycled content rate. They are also easy to fabricate and can be cut, bent, and shaped into various forms. Disadvantages include lower strength compared to steel, which may require thicker sheets for certain applications. They can also be more expensive than some other materials, and their light reflection can sometimes be a concern in certain environments.</p>

- Q: I'm trying to use as little aluminum as possible as it can be related to health problems, and I'm just trying to be a little more careful. I just bought the Emerilware pro-clad pot and pan set, and it's stainless steel but says Emerilware Pro-Clad is constructed with an aluminum core bonded between two layers of stainless steel ideal for... Therefore, I'm still cooking with aluminum. Is it safer since it's between 2 pieces of stainless steel? Does any stainless steel cookware not use aluminum? Thanks.

- Aluminum and titanium are lighter, but they are easier to scratch (due to non-stick coatings) and do not hold heat as well. Stainless steel is more durable and distributes heat better. You can also clean it with sand or ice without having to worry about scratching it. If you are going to fry with it, you will need oil since the food will stick without it. When I go ultra light, I use a jet boil with a titanium pot to boil water for cooking. When I want to go gourmet, I use the GSI stainless steel set.

- Q: What are the common sizes of aluminum sheets?

- The common sizes of aluminum sheets vary, but some of the standard sizes include 4x8 feet, 4x10 feet, and 5x10 feet. These sizes are widely available and commonly used in various industries.

- Q: 25mm thickness of hard aluminum processing to 6mm how to process, thank you all

- For a subject, use a saw. Can produce several, milling too wasteful.

- Q: What are the different methods of cutting aluminum sheets?

- To cut aluminum sheets, one can utilize various methods based on specific requirements and material thickness. Some commonly employed techniques include: 1. Shearing: By means of a shearing machine, straight lines can be cut in the aluminum sheet. The machine applies force to a blade, resulting in material separation. Shearing is a swift and efficient approach, especially suitable for thinner gauges. 2. Sawing: For cutting aluminum sheets, circular or bandsaws equipped with specialized metal-cutting blades are commonly employed. This method allows for greater precision and controlled cuts, making it ideal for thicker sheets. 3. Laser cutting: This highly precise and efficient technique employs a concentrated beam of light to melt and vaporize the aluminum, resulting in a clean and smooth cut. Laser cutting is particularly advantageous for intricate designs and complex shapes. 4. Waterjet cutting: This method involves the use of a high-pressure stream of water mixed with abrasive particles to cut through aluminum sheets. It is applicable to various thicknesses and allows for precise cuts without generating heat. Waterjet cutting is often preferred for thicker sheets or when high precision is required. 5. Plasma cutting: By employing a high-temperature plasma torch, aluminum sheets can be melted and cut. The torch generates an electric arc, ionizing the gas and creating a plasma state. Although versatile and capable of cutting through different thicknesses, plasma cutting may yield rougher edges in comparison to laser or waterjet cutting. When selecting the most suitable method for cutting aluminum sheets, it is crucial to consider project-specific requirements such as desired cut quality, speed, and complexity.

- Q: What is the weight of aluminium plate now?

- The following is the density of each series of aluminum sheets for reference.Pure aluminum 2.7 TC7 4.4Antirust aluminium LF2, LF43 2.68, TC8 4.48LF3 2.67 TC9 4.52LF5, LF10, LF11 2.65, TC10 4.53LF6 2.64 pure nickel, anode nickel, electric vacuum nickel 8.85LF21 2.73, nickel, copper, nickel, magnesium, nickel silicon alloy 8.85Hard aluminium, LY1, LY2, LY4, LY6 2.76, Ni Cr alloy 8.72LY3 2.73 (Zn0.1, Zn1, zinc, Zn2, Zn3) 7.15LY7, LY8, LY10, LY11, LY14 2.8, cast zinc 6.86LY9, LY12 2.78, 4-1 casting zinc aluminum alloy 6.9LY16, LY17 2.84, 4-0.5 casting zinc aluminum alloy 6.75Wrought aluminium LD2, LD30 2.7 lead and lead antimony alloy 11.37LD4 2.65 lead anode plate 11.33LD5 2.75

- Q: What are the different heat treatment options available for aluminum sheets?

- Aluminum sheets can undergo various heat treatment options, each imparting distinct characteristics and properties to the material. 1. Annealing: To relieve internal stresses and enhance ductility and machinability, the aluminum sheet is heated to a specific temperature and gradually cooled down. 2. Solution Heat Treatment: This treatment involves subjecting the aluminum sheet to high temperatures and swiftly cooling it in water or another cooling medium. By dissolving and homogenizing alloying elements, solution heat treatment improves strength and hardness. 3. Precipitation Hardening: Also known as age hardening, this treatment is typically performed after solution heat treatment. It entails heating the aluminum sheet at a lower temperature for a specific duration, allowing alloying elements to precipitate and form fine particles. This process enhances strength and hardness without compromising ductility. 4. Stress Relieving: To alleviate residual stresses developed during fabrication or machining, the aluminum sheet is heated to a specific temperature and gradually cooled. This reduces the risk of distortion or cracking. 5. Hardening: Achieving hardening involves heating the aluminum sheet to a specific temperature and rapidly quenching it. This process boosts strength and hardness, making the material suitable for applications requiring high strength-to-weight ratios. It is important to consider the desired properties and application requirements when selecting a heat treatment option for aluminum sheets. Seeking guidance from a metallurgical expert or referring to material specifications can aid in determining the most appropriate choice.

- Q: Can aluminum sheets be used for automotive heat shields?

- Yes, aluminum sheets can be used for automotive heat shields. Aluminum is a popular choice for heat shields in the automotive industry due to its excellent thermal conductivity and heat resistance properties. It has a high melting point and can effectively dissipate heat, making it suitable for protecting various components from excessive heat exposure. Additionally, aluminum sheets are lightweight and easy to shape, allowing for custom designs to fit specific automotive applications. Overall, aluminum sheets are a reliable and cost-effective option for automotive heat shields.

Send your message to us

5mm Cost Price Alumet Baked Enamel Embossed Aluminum Alloy Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords