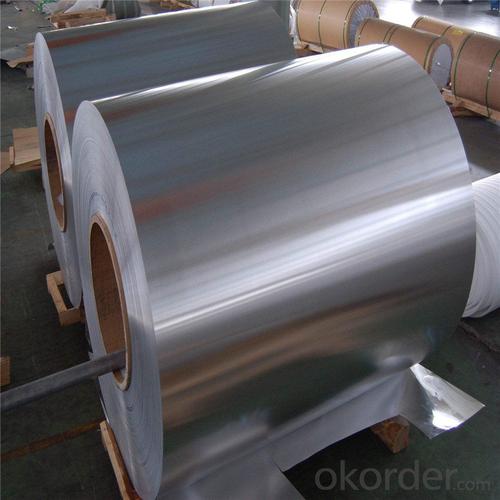

5754 Coated Aluminum Coil - 1050/1100/1070 1060 Aluminum Coil with Good Price and Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Coil 1060/1050/1100/1070

Chemical Composition:

| COMPOSITION % Percent | |||||||||

Si | Fe | Cu | Mn | Mg | Zn | Ti | Other elements | Al | ||

Each | Total | |||||||||

1070 | 0.200 | 0.250 | 0.040 | 0.030 | 0.030 | 0.040 | 0.030 | 0.03 | — | 99.70 |

1060 | 0.250 | 0.350 | 0.050 | 0.030 | 0.030 | 0.050 | 0.030 | 0.03 | — | 99.60 |

1050 | 0.250 | 0.400 | 0.050 | 0.050 | 0.050 | 0.050 | 0.030 | 0.03 | — | 99.50 |

1100 | Si+Fe:0.95 | 0.05-0.2 | 0.050 | — | 0.100 | — | 0.05 | 0.15 | 99.00 | |

Applications:

High electro conductibility, and heat conductibility, good formability, bending and extending, commonly used for Chemical and food storage, electric conductor, soft pipe for brewing industry, heat exchanger, decoration etc.

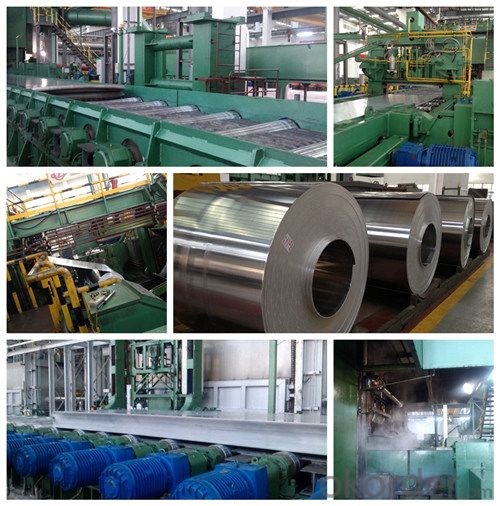

Production line:

- Q: How do aluminum coils contribute to sustainability efforts?

- Aluminum coils contribute to sustainability efforts by being highly recyclable, energy-efficient, and durable. They can be recycled repeatedly without losing their properties, reducing the need for virgin aluminum production and minimizing waste. Additionally, aluminum coils have a low weight-to-strength ratio, resulting in energy savings during transportation. Their durability ensures a longer lifespan, reducing the frequency of replacements and the associated environmental impact. Overall, aluminum coils play a crucial role in promoting a more sustainable and circular economy.

- Q: What are the advantages of using aluminum coils?

- Using aluminum coils in various applications offers several advantages. To begin with, aluminum coils are known for their lightweight properties, distinguishing them from materials like copper or steel. Their reduced weight makes handling and transportation easier, ultimately decreasing the overall weight of the system or product in which they are utilized. Moreover, their lightweight nature contributes to simplified installation and maintenance procedures. Additionally, aluminum coils exhibit exceptional corrosion resistance. They naturally develop a protective oxide layer on their surface, preventing further oxidation and corrosion, even in harsh environments. This quality renders them particularly suitable for outdoor applications or areas exposed to high humidity or chemicals. Furthermore, aluminum coils possess high thermal conductivity, enabling efficient heat transfer. This characteristic proves valuable in heating, ventilation, and air conditioning (HVAC) systems, as it enhances energy efficiency and reduces overall energy consumption. In addition, aluminum coils demonstrate remarkable flexibility, allowing them to be easily formed into various shapes and sizes. This flexibility grants designers greater freedom and customization options, making aluminum coils suitable for a wide range of applications. They can be effortlessly bent, cut, or shaped to meet specific requirements without compromising structural integrity. Lastly, aluminum coils are cost-effective. Aluminum is abundant and readily available, making it more affordable compared to other materials. Moreover, its lightweight nature reduces transportation costs, while its corrosion resistance eliminates the need for frequent maintenance and replacements, resulting in long-term cost savings. To summarize, the advantages of using aluminum coils encompass their lightweight properties, exceptional corrosion resistance, high thermal conductivity, flexibility, and cost-effectiveness. These characteristics have established aluminum coils as a popular choice in various industries, including construction, automotive, aerospace, and HVAC.

- Q: I was wondering if you could mold clay into a sphere then fill it with aluminum. Then put it over a fire and wait until the aluminum melts then put it in a freezer and it would come out as a sturdy, aluminum sphere. Thanks!

- Do not try this at home! Seriously, this is exactly the kind of process that is used for casting metals. However, you need to have very strong molds with no cracks in them. Also, aluminum presents special problems. Solid aluminum does not corrode the way iron does, because it very quickly forms a protective tough layer of aluminum oxide. But molten aluminum can catch fire, with devastating consequences.

- Q: How are aluminum coils used in the production of furniture?

- Aluminum coils are widely used in the production of furniture due to their various beneficial properties. These coils are typically made from high-quality aluminum alloy, which offers excellent corrosion resistance, durability, and lightweight characteristics. In the furniture manufacturing process, aluminum coils are primarily used for creating the framework or structure of the furniture pieces. They are often formed into various shapes and profiles to provide the necessary strength and rigidity required for the furniture item. The coils can be easily bent, cut, and joined together to create different components such as chair frames, table legs, or cabinet structures. This versatility allows manufacturers to design and produce furniture with intricate and customized shapes and sizes. Moreover, aluminum coils are highly adaptable to different finishing techniques. They can be anodized, painted, or powder-coated to enhance their aesthetic appeal and provide additional protection against wear and tear. This makes aluminum-coiled furniture resistant to scratches, stains, and fading, ensuring longevity and a visually appealing appearance. Additionally, aluminum coils offer a lightweight alternative to other materials like steel or wood, making furniture easier to transport and handle. This is particularly advantageous in the case of outdoor furniture or pieces that need to be frequently moved or rearranged. Furthermore, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, allowing manufacturers to reduce their carbon footprint and contribute to a more sustainable production process. In summary, aluminum coils play a vital role in the production of furniture by providing strength, durability, versatility, and aesthetic appeal. Their use in furniture manufacturing helps create lightweight, customizable, and sustainable furniture pieces that meet the demands of modern consumers.

- Q: Can aluminum coils be used in the manufacturing of electronic devices?

- Electronic devices can utilize aluminum coils due to their versatile nature and widespread use in various industries, including electronics. Transformers, inductors, and other components of electronic devices often incorporate aluminum coils. The lightweight nature of aluminum coils is one of their major benefits in electronic devices. Compared to materials like copper, aluminum is significantly lighter, making it easier to handle and transport. Moreover, aluminum possesses excellent thermal conductivity, promoting efficient heat dissipation within electronic devices. In addition, aluminum coils exhibit resistance to corrosion, which is vital in electronic applications where exposure to moisture or harsh environments is likely. This corrosion resistance plays a crucial role in extending the lifespan of electronic devices and ensuring their reliability. Furthermore, aluminum coils can be easily shaped and sized to fit various electronic device designs. This flexibility allows for customization to meet specific requirements, such as fitting into compact spaces or achieving desired electrical characteristics. In summary, aluminum coils offer numerous advantages in the manufacturing of electronic devices, including their lightweight nature, good thermal conductivity, resistance to corrosion, and flexibility in design.

- Q: This question asks for methods to determine whether an aluminum coil is safe for use.

- <p>To determine if your aluminum coil is safe to use, first, check for any visible signs of damage such as cracks, corrosion, or deformation. Ensure that the coil meets the required specifications for your application, including thickness, width, and alloy type. Verify the coil's compliance with safety standards and certifications relevant to your industry, such as ASTM or ISO standards. Test the coil's mechanical properties to ensure it has the necessary strength and ductility. Finally, consider the coil's history and usage; it should not have been exposed to extreme temperatures or corrosive environments that could compromise its integrity. Consulting with a materials expert or conducting a thorough inspection can provide further assurance of the coil's safety.</p>

- Q: My budgies took at bath in an aluminum pie tin today. At first they bit it just because it was their first time. Should I be worried that they might get poisoned?

- Nah, when I was a baby I took baths in aluminum pie tins all the time.

- Q: This question asks about the duration an aluminum coil can last before it needs to be replaced or becomes unusable.

- <p>The lifespan of an aluminum coil can vary significantly depending on its application, quality of the material, and environmental conditions. Generally, if properly stored and used, aluminum coils can last for several years without significant degradation. However, in industrial settings where coils are subjected to continuous use and harsh conditions, their lifespan might be reduced to a few years or even less. Regular maintenance and inspection can help extend the lifespan of aluminum coils.</p>

- Q: How are aluminum coils processed and shaped into different forms?

- Aluminum coils go through a series of processes to shape them into different forms. The first step is the uncoiling process, where the coil is unwound and straightened. This allows for easier handling and further processing. Next, the aluminum coil goes through a cleaning process to remove any dirt, grease, or other impurities that may be present on the surface. This is done to ensure that the final product has a clean and smooth finish. After cleaning, the coil is typically subjected to a series of heat treatments to improve its mechanical properties. This process, known as annealing, involves heating the coil to a specific temperature and then slowly cooling it down. Annealing helps to increase the aluminum's ductility, making it easier to shape and form. Once the coil is annealed, it can be processed into different forms using various techniques. One common method is called roll forming, where the coil is passed through a series of rollers that gradually bend and shape it into the desired form. Roll forming is often used to create sheets, strips, or tubes. Another popular shaping technique is called stamping, which involves using a die and press to cut or shape the aluminum coil into specific shapes. Stamping is commonly used to create intricate designs or components with precise dimensions. In addition to roll forming and stamping, other methods such as extrusion, bending, and welding can also be used to shape aluminum coils into different forms. These processes allow for the creation of a wide range of products, including automotive parts, household appliances, construction materials, and more. Overall, the processing and shaping of aluminum coils involve a combination of cleaning, heat treatment, and various forming techniques. These processes ensure that the aluminum is transformed into the desired form while maintaining its structural integrity and desired properties.

- Q: What are the necessary safety measures to be taken while handling and using aluminum coils?

- <p>When using aluminum coil, safety precautions include wearing appropriate personal protective equipment such as gloves and safety glasses to prevent cuts and eye injuries. Ensure good ventilation to avoid inhaling aluminum dust or fumes. Keep the work area clean and free from clutter to prevent tripping hazards. Use proper tools to handle the coils to avoid strain or injury. Be cautious of electrical hazards if the aluminum coil is being used in conjunction with electrical equipment. Always follow the manufacturer's guidelines for safe operation and storage of aluminum coils.</p>

Send your message to us

5754 Coated Aluminum Coil - 1050/1100/1070 1060 Aluminum Coil with Good Price and Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords